Overview

This article delineates ten cost reduction strategies for manufacturers designed to enhance efficiency. These strategies encompass:

- Renegotiating vendor contracts

- Consolidating suppliers

- Implementing e-procurement software

Each strategy is bolstered by actionable tips and data that illustrate potential savings, thereby offering a comprehensive framework for manufacturers to pinpoint and eradicate inefficiencies within their operations.

Introduction

Manufacturers today confront an ever-evolving landscape of challenges and opportunities, with the imperative to enhance efficiency and reduce costs at an all-time high. By implementing strategic cost reduction initiatives, businesses can not only elevate their bottom line but also position themselves for sustainable growth in an increasingly competitive market.

However, the pressing question remains: what specific actions can manufacturers undertake to effectively streamline operations and maximize savings? This article explores ten actionable strategies that empower manufacturers to:

- Identify inefficiencies

- Renegotiate contracts

- Foster a cost-conscious culture

Ultimately, these strategies pave the way for enhanced profitability and operational excellence.

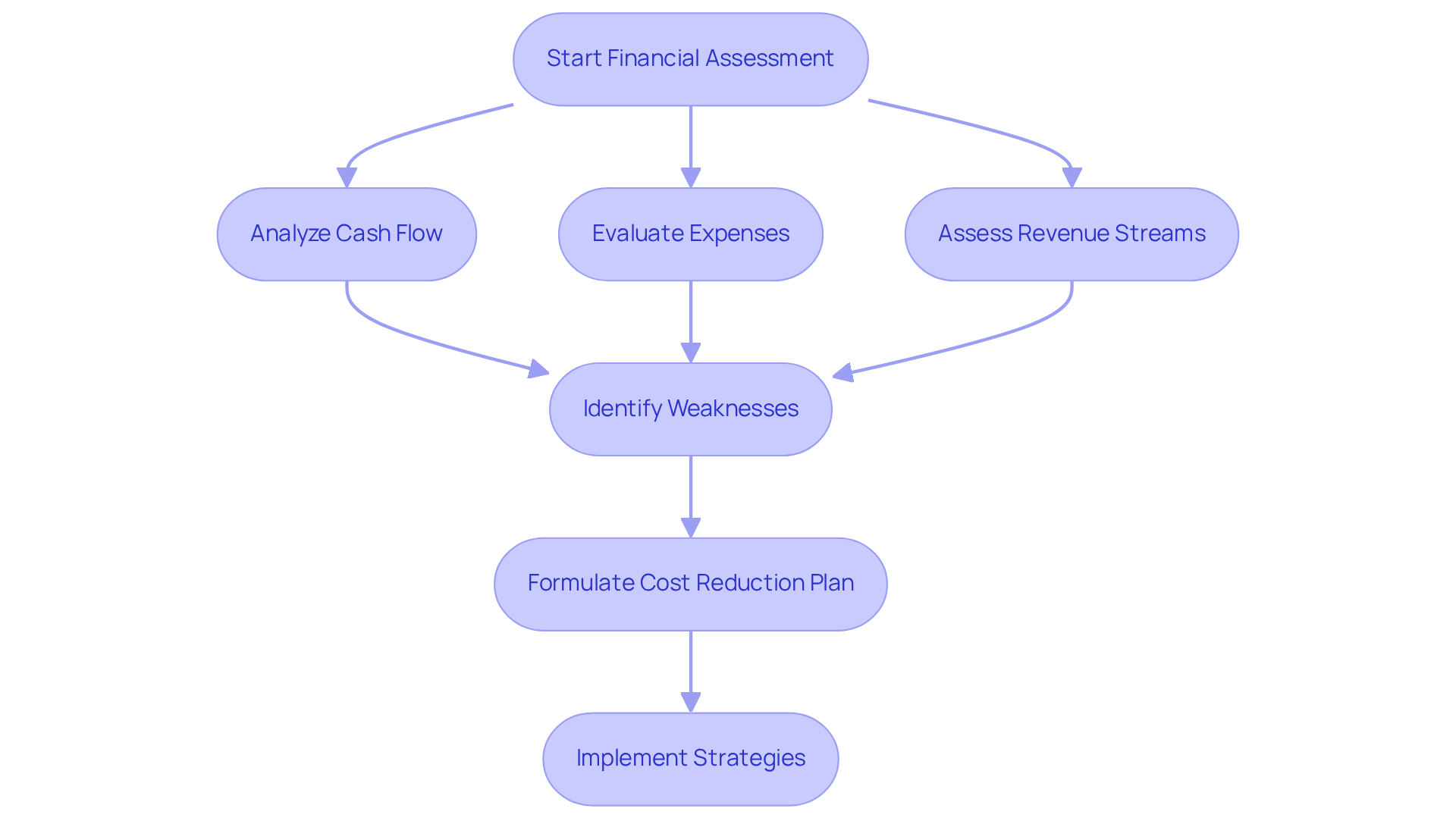

Transform Your Small/ Medium Business: Comprehensive Financial Assessment for Cost Reduction

A thorough financial assessment is essential for small to medium manufacturers, involving an in-depth analysis of cash flow, expenses, and revenue streams. Our team will pinpoint underlying business issues and collaborate to formulate a plan that mitigates weaknesses, enabling the business to reinvest in key strengths. This process uncovers inefficiencies and highlights opportunities for savings. For instance, examining historical monetary data can reveal spending patterns that indicate unnecessary expenses, while benchmarking against industry standards can uncover areas ripe for improvement. By gaining a clear understanding of your economic landscape, you can strategically prioritize cost reduction strategies for manufacturers.

Actionable Tip: Utilize analysis tools like QuickBooks or Xero to automate data gathering and reporting, facilitating the recognition of trends and anomalies in your spending habits. This approach not only enhances accuracy but also empowers you to make informed decisions that drive efficiency and profitability.

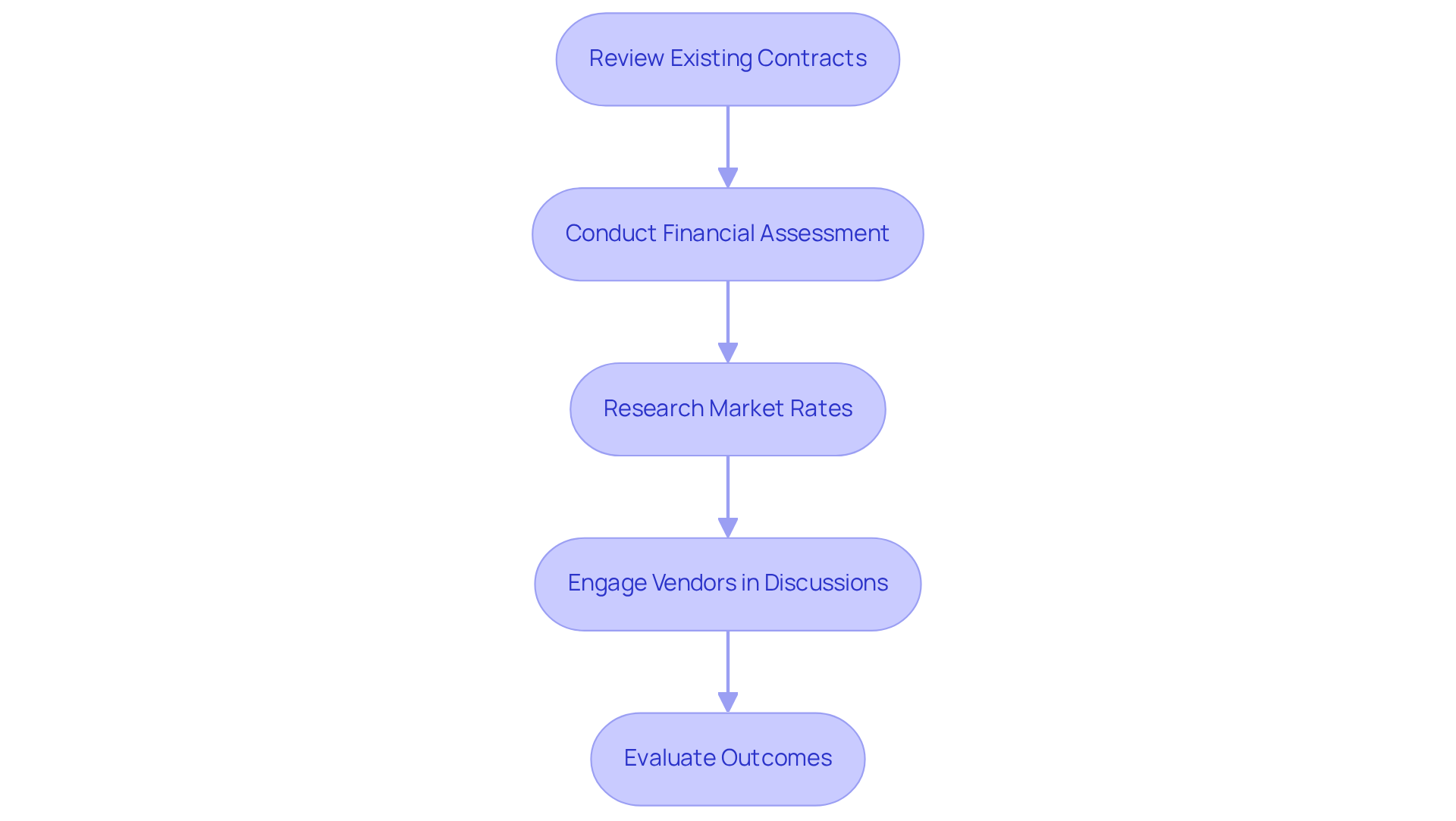

Renegotiate Vendor Contracts: Unlock Savings in Supply Chain Management

Renegotiating vendor agreements is a crucial approach for manufacturers to unlock substantial reductions in supply chain management through cost reduction strategies for manufacturers. Begin by thoroughly reviewing existing contracts to pinpoint outdated or unfavorable terms. A comprehensive financial assessment can help identify opportunities for cost reduction strategies for manufacturers, allowing them to preserve cash and reduce liabilities, which makes it easier to negotiate better terms. Research current market rates for similar services; this information serves as a powerful tool during negotiations. Engage in transparent discussions with vendors to communicate your needs and explore opportunities that align with cost reduction strategies for manufacturers, such as bulk purchasing or long-term agreements that may lead to substantial discounts. For instance, firms have realized an initial cost reduction of 28.5% and a further cost prevention of 24.3% over two years through successful contract renegotiation, illustrating effective cost reduction strategies for manufacturers that result in millions in benefits each year. Moreover, a worldwide agricultural chemicals firm achieved $75 million in cost reduction strategies for manufacturers by renegotiating labor service agreements.

Actionable Tip: Schedule regular evaluations of vendor contracts to ensure they remain competitive and aligned with your changing organizational needs. Utilize real-time analytics to monitor the success of your negotiations and track savings by spend category as part of your cost reduction strategies for manufacturers, helping to identify strengths and areas for improvement. Consider extending payment terms with high spend vendors to boost cash flow.

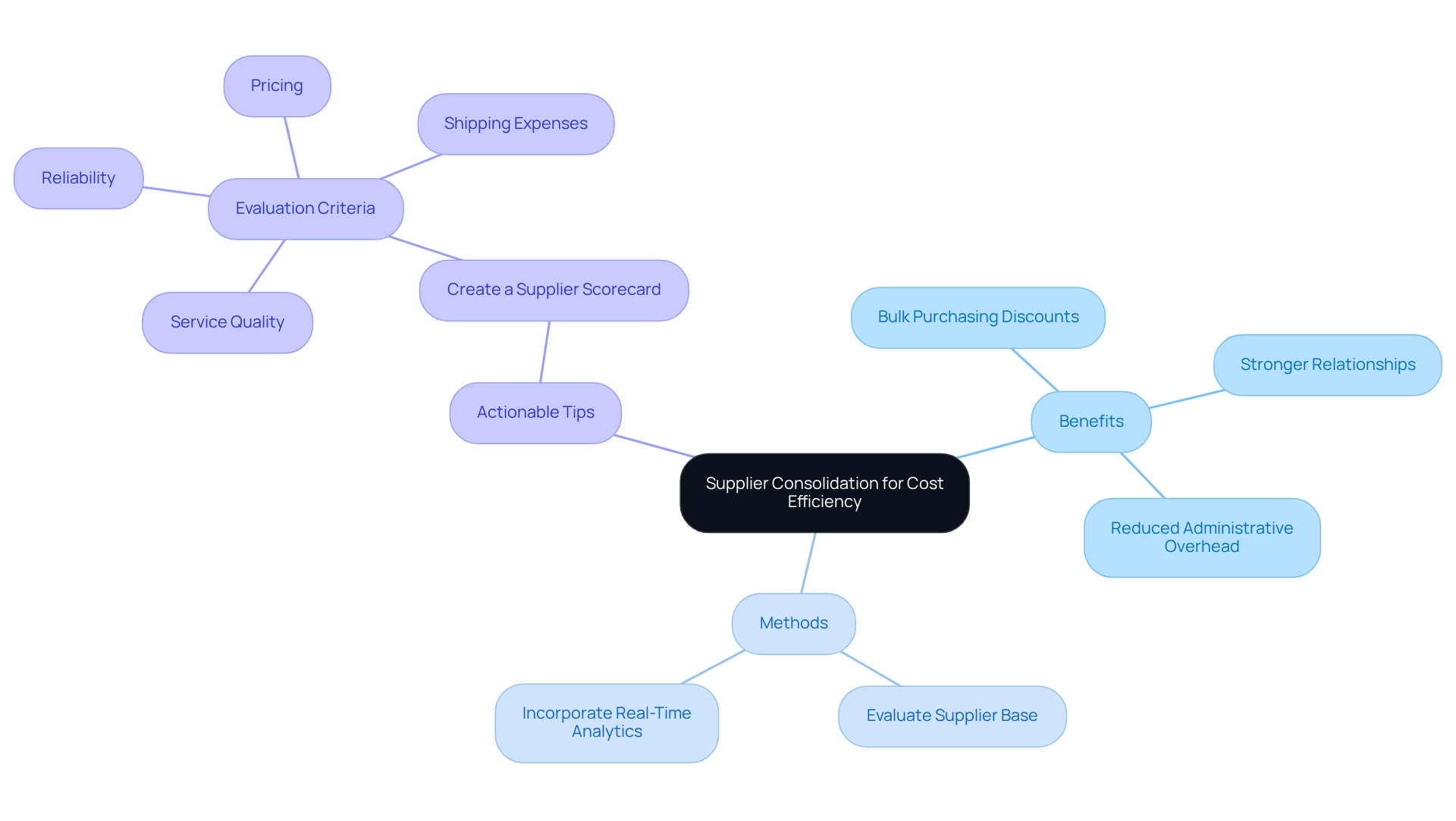

Consolidate Suppliers: Streamline Procurement for Cost Efficiency

Consolidating suppliers represents a strategic approach that is part of cost reduction strategies for manufacturers, aimed at reducing the number of vendors to streamline procurement processes. This method not only facilitates bulk purchasing discounts but also fosters stronger relationships with key suppliers. By evaluating your current supplier base, you can identify those capable of providing multiple products or services, which allows for more effective negotiations and better terms. This focus on fewer suppliers significantly reduces administrative overhead, enabling procurement teams to concentrate on strategic initiatives rather than managing numerous vendor relationships.

Moreover, incorporating real-time analytics into your supplier management can further enhance this process. Utilizing Transform Your Small/Medium Business's client dashboard, which provides continuous performance monitoring, allows procurement teams to make informed decisions quickly, adapting strategies based on current data. This approach not only supports a shortened decision-making cycle but also aids in diagnosing business health effectively.

Actionable Tip: Create a supplier scorecard to evaluate performance based on reliability, pricing, service quality, and shipping expenses. This tool will assist in determining which suppliers can be merged, ultimately improving procurement efficiency and generating financial benefits by implementing cost reduction strategies for manufacturers. Statistics suggest that organizations can attain purchasing expense reductions of 8-12% through effective supplier consolidation, a projection based on trends that highlights the financial advantages of this strategy in 2025.

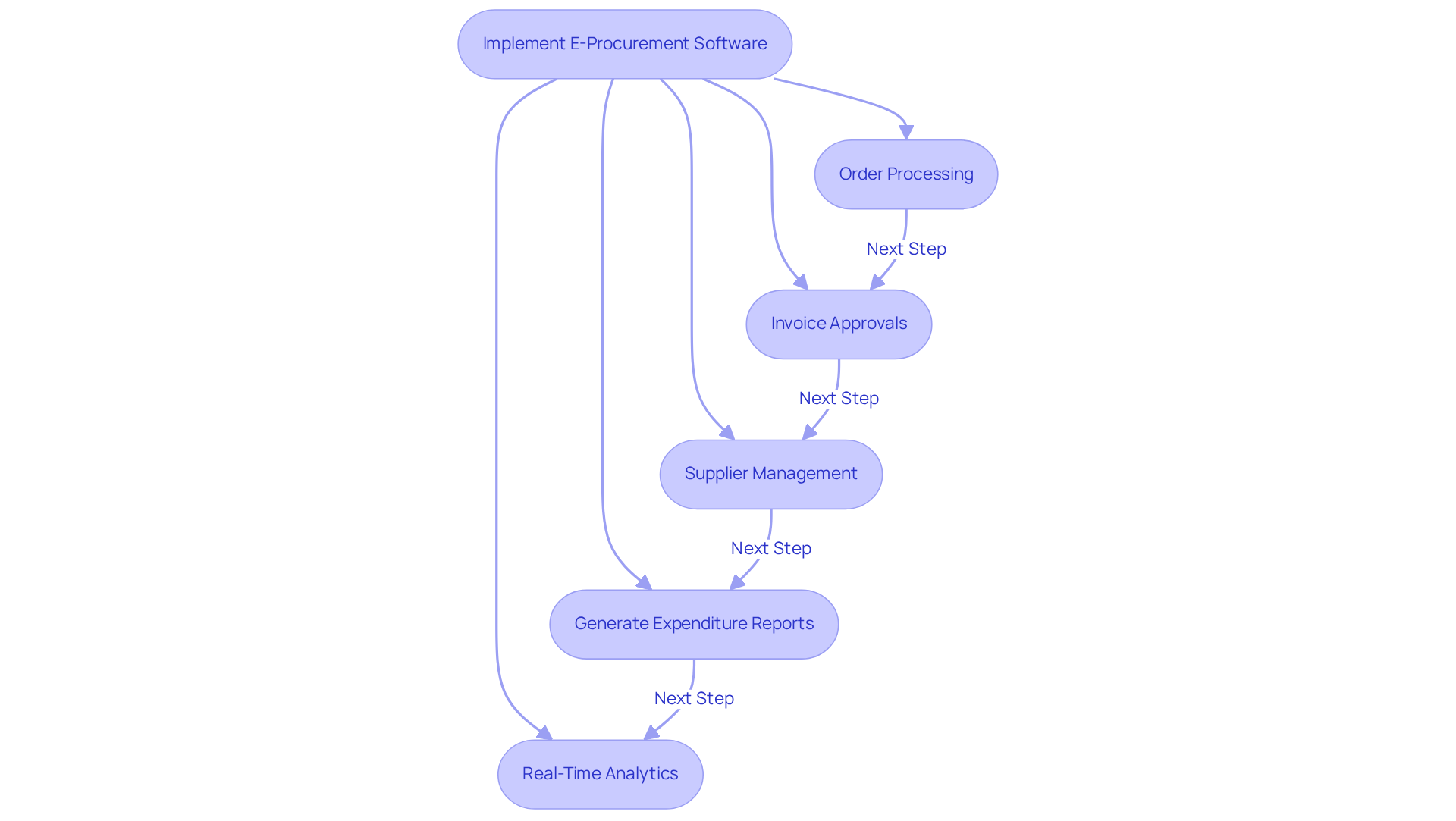

Implement E-Procurement Software: Automate and Optimize Purchasing Processes

Implementing e-procurement software can dramatically enhance purchasing processes by automating key tasks such as order processing, invoice approvals, and supplier management. This automation not only minimizes manual errors but also significantly reduces processing times, allowing teams to focus on strategic activities. Companies utilizing e-procurement solutions have reported savings of up to $20,000 in goods and services over just four months, demonstrating effective cost reduction strategies for manufacturers.

Moreover, e-procurement platforms offer critical insights into spending patterns, enabling organizations to make informed purchasing decisions. With the capability to produce expenditure reports in seconds instead of hours, organizations can attain enhanced visibility and control over their procurement activities. As of 2025, the trend towards adopting e-procurement technology continues to grow, with many manufacturers recognizing its role in cost reduction strategies for manufacturers by optimizing purchasing processes and driving efficiency. Notably, over 40 percent of surveyed companies have decentralized purchasing processes, highlighting a significant challenge that e-procurement can effectively address.

Furthermore, the incorporation of real-time analytics within e-procurement systems facilitates continuous oversight of operational performance, allowing organizations to modify strategies swiftly based on data-informed insights. This capability supports a streamlined decision-making process, essential for effective cost reduction strategies for manufacturers in various industries.

Actionable Tip: Choose an e-procurement platform that effortlessly connects with your current accounting systems and tackles specific issues, such as maverick spending and compliance monitoring, to guarantee smooth data flow and thorough reporting.

Embrace Remote Work Model: Reduce Overhead and Increase Flexibility

Embracing a remote work model presents substantial opportunities for businesses to adopt cost reduction strategies for manufacturers by significantly cutting costs associated with office space, utilities, and supplies. Companies adopting flexible work arrangements not only attract a broader talent pool but also enhance employee retention rates. For instance, research shows that organizations can save as much as $11,000 per employee annually by transitioning to a hybrid model, which encompasses reductions in real estate expenses and boosts productivity among remote workers. Moreover, support expenses average $1,231 per virtual office employee, underscoring the financial implications of remote work.

To implement this model effectively, establishing clear communication channels and equipping employees with the necessary tools for remote collaboration is crucial. Regular check-ins with remote employees can help maintain engagement and ensure productivity remains high. For example, utilizing video conferencing tools for weekly team meetings fosters connection and accountability. Furthermore, HR leaders assert that flexible work options significantly improve employee satisfaction, with 89% believing such arrangements enhance overall well-being. Notably, 79% of participants in a FlexJobs survey indicated they would feel more loyal to their employer if offered flexible remote work arrangements. This approach not only cultivates a more committed workforce but also positions companies to thrive in a competitive landscape, particularly in the manufacturing sector where retention is vital for operational success.

Review and Renegotiate Office Leases: Cut Real Estate Costs

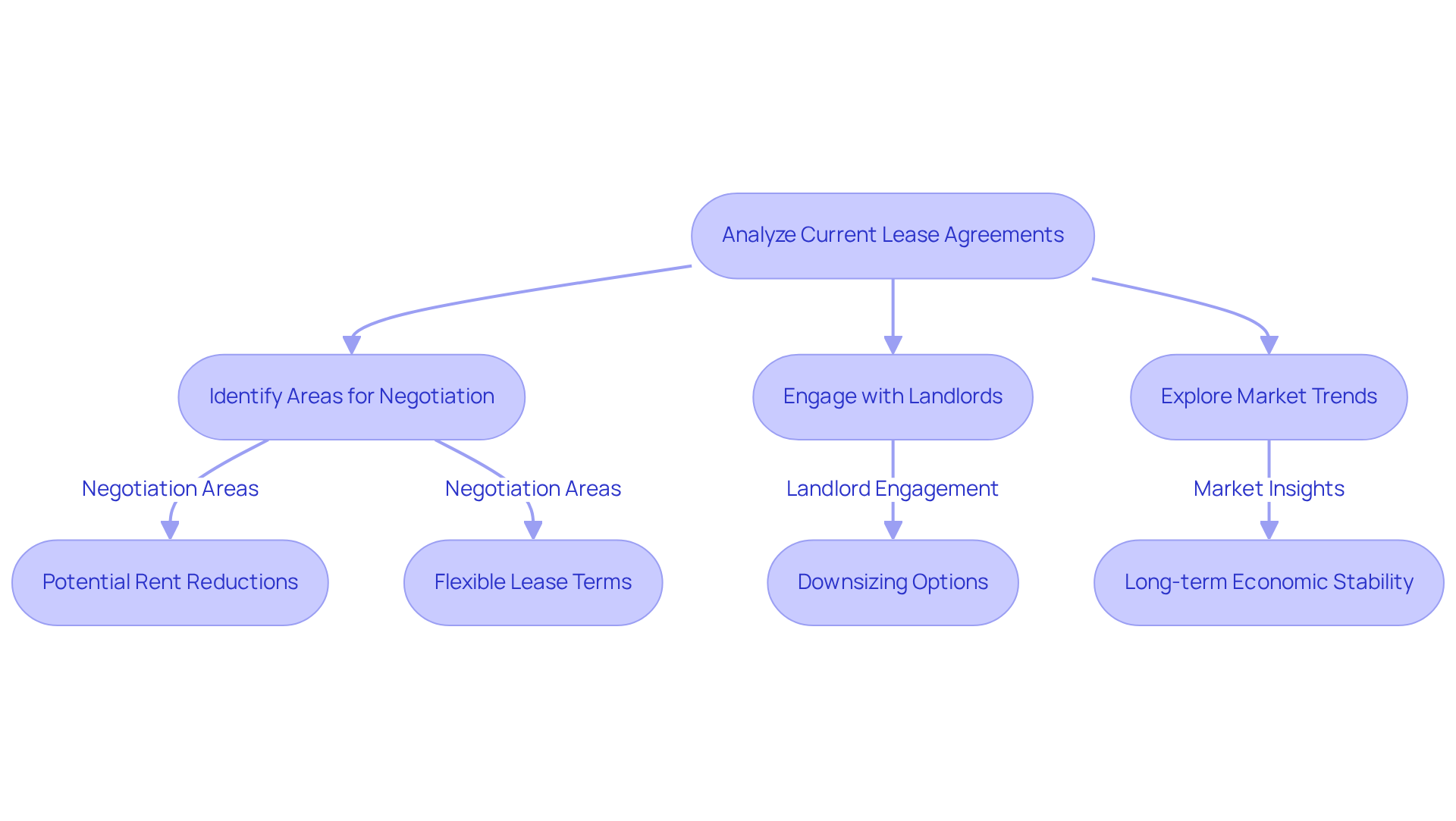

Examining and renegotiating office leases is one of the cost reduction strategies for manufacturers aiming to reduce real estate expenses. Begin by conducting a thorough analysis of your current lease agreements to identify areas ripe for negotiation, such as potential rent reductions or more flexible lease terms. Engaging proactively with landlords can initiate discussions about your specific needs, including options for downsizing or relocating to more cost-effective spaces.

Current trends indicate that many companies are exploring shorter lease terms, with 49% of respondents considering this option, reflecting a growing demand for flexibility in office arrangements. Moreover, leveraging market insights can significantly enhance your negotiating position.

Actionable Tip: Stay informed about market trends and utilize them during negotiations to secure the most favorable terms possible. This approach not only aids in implementing cost reduction strategies for manufacturers but also positions your enterprise for long-term economic stability.

Leverage Accounting Automation: Enhance Efficiency and Reduce Labor Costs

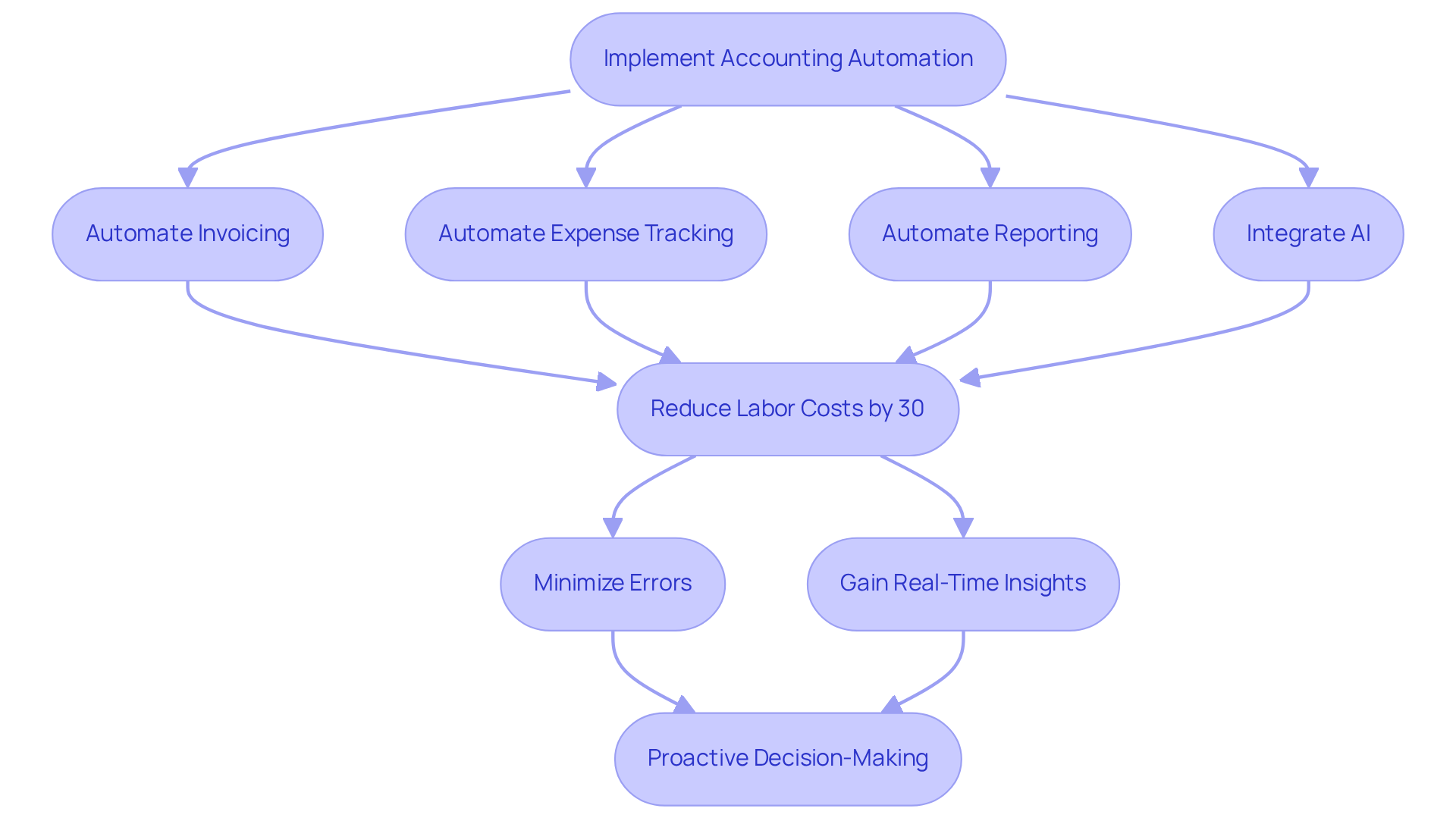

Harnessing accounting automation can significantly enhance monetary operations for manufacturers. Companies can implement cost reduction strategies for manufacturers by automating critical tasks such as invoicing, expense tracking, and reporting, achieving substantial reductions in labor costs—often exceeding 30%—while minimizing errors associated with manual processes. This transformation not only saves valuable time but also delivers real-time insights into financial performance, facilitating proactive decision-making and ongoing monitoring of organizational health. Moreover, organizations that integrate AI with automation can achieve significant labor savings, highlighting the importance of implementing cost reduction strategies for manufacturers compared to those relying solely on traditional automation, underscoring the necessity of selecting the right software. This strategy fosters a streamlined decision-making cycle, empowering teams to make decisive actions that sustain and elevate organizational performance.

Actionable Tip: Invest in accounting software that seamlessly integrates with other organizational systems, such as CRM and ERP platforms. This integration optimizes workflows, enhances data accuracy, supports compliance, and bolsters security, ultimately leading to improved operational efficiency.

Review and Reduce Subscriptions: Eliminate Unnecessary Expenses

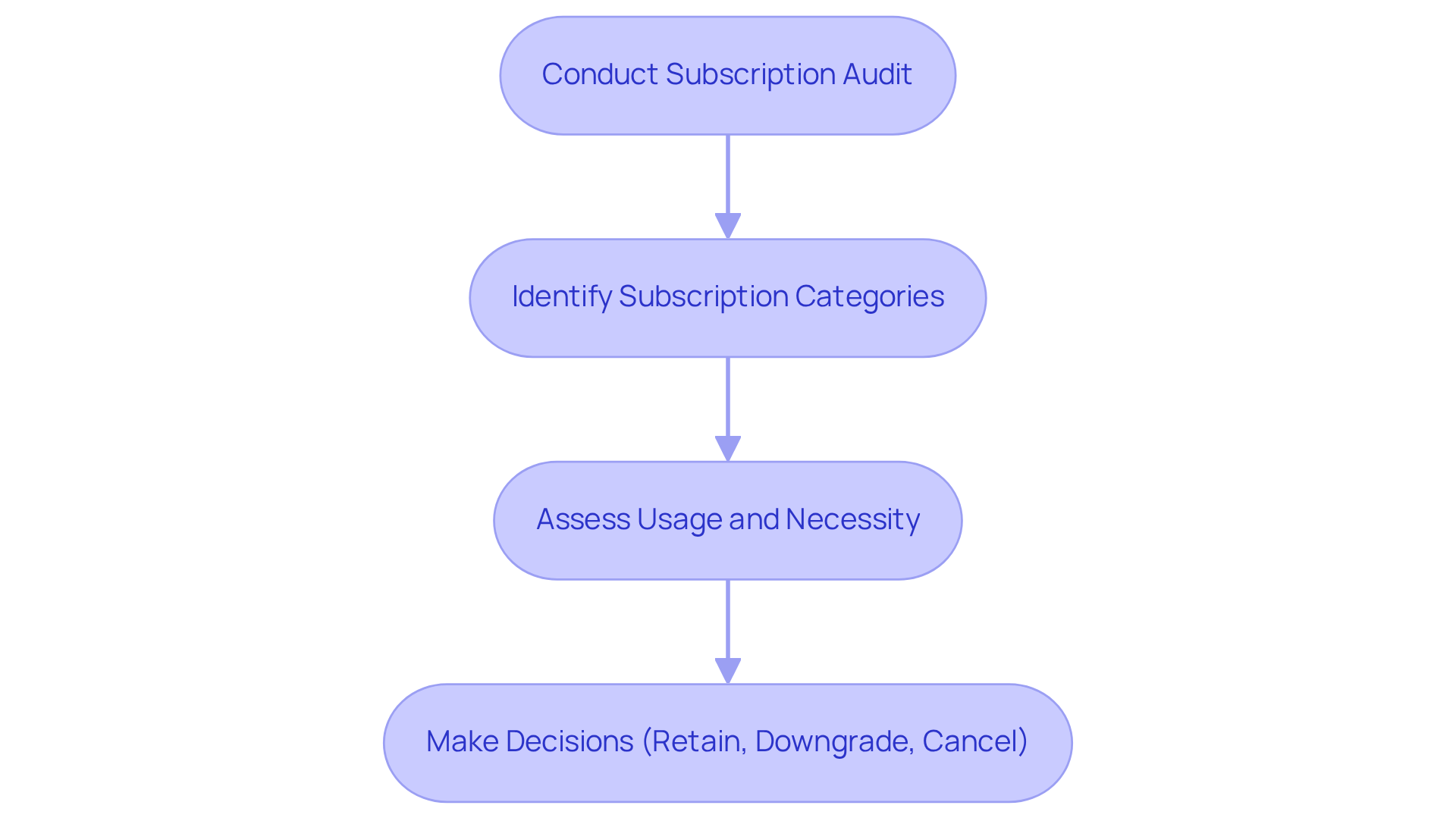

Conducting a subscription audit is a vital strategy for manufacturers looking to implement cost reduction strategies by identifying and eliminating unnecessary expenses. Many organizations inadvertently pay for services that are either underutilized or no longer essential. By systematically reviewing all subscriptions, companies can identify cost reduction strategies by categorizing them based on usage and necessity, enabling informed decisions on which services to retain, downgrade, or cancel entirely.

Our team facilitates a streamlined decision-making process throughout this audit, empowering your organization to take decisive action swiftly. Moreover, leveraging real-time analytics through subscription management tools can significantly enhance this process. These tools simplify the identification of wasteful expenditures, allowing businesses to utilize cost reduction strategies and improve overall financial efficiency. In 2025, companies that adeptly manage their subscriptions can anticipate average savings of up to 30%, profoundly impacting their bottom line. Financial analysts underscore that adopting cost reduction strategies by reducing unnecessary subscriptions not only conserves cash flow but also reallocates resources towards more productive investments, ultimately driving operational efficiency.

Reduce Inventory Waste: Optimize Stock Management for Cost Savings

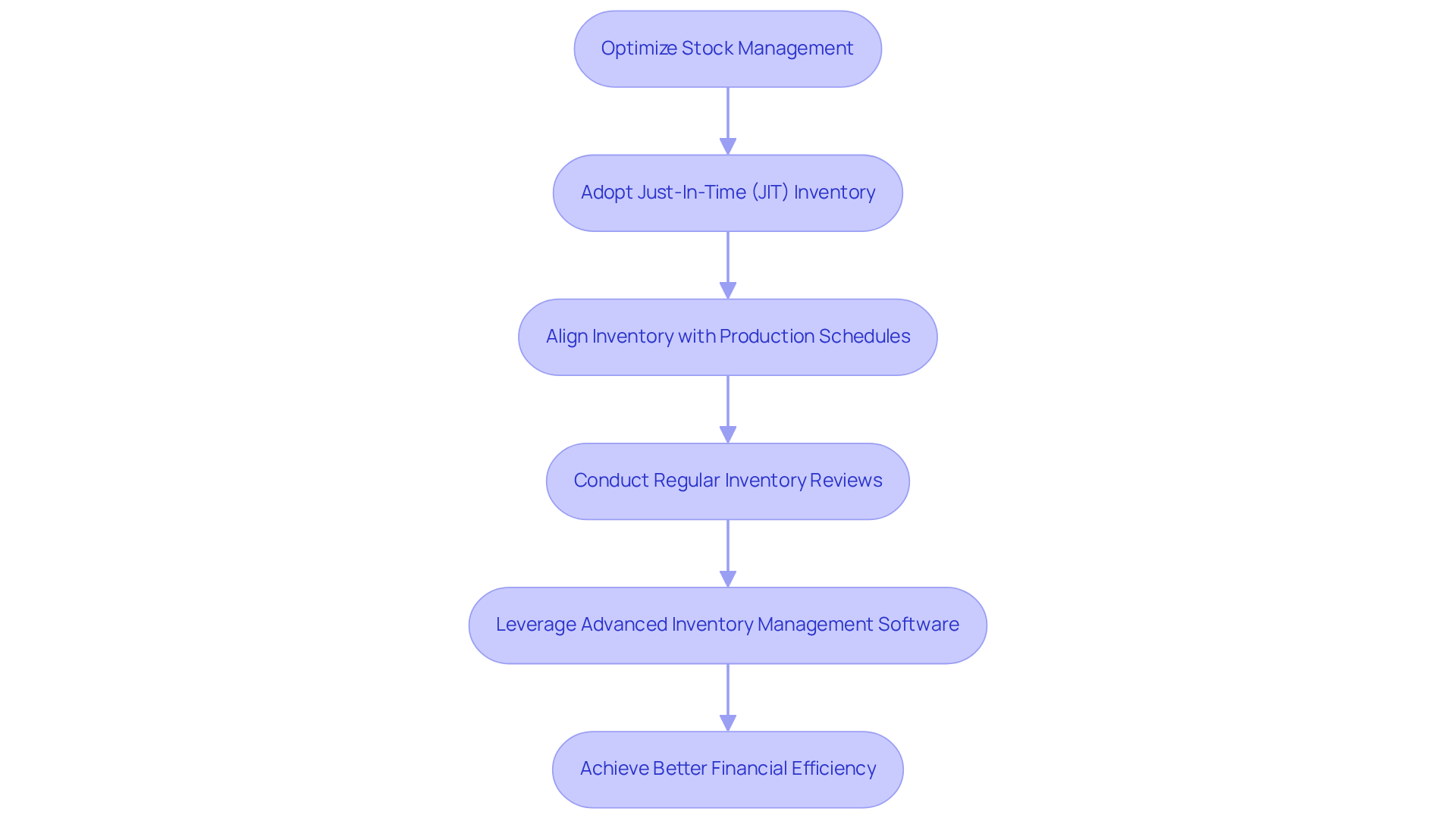

Minimizing inventory waste is essential for manufacturers to adopt cost reduction strategies for manufacturers and improve financial efficiency. By adopting Just-In-Time (JIT) inventory management, businesses can utilize cost reduction strategies for manufacturers to significantly reduce surplus stock and decrease holding expenses. Aligning inventory levels closely with production schedules is essential in implementing cost reduction strategies for manufacturers, as it not only reduces waste but also enhances cash flow. Furthermore, regular reviews of inventory levels and the implementation of cost reduction strategies for manufacturers, combined with adjustments in purchasing practices based on accurate demand forecasts, help prevent overproduction and stockouts.

Actionable Tip: Leverage advanced inventory management software to gain real-time insights into stock levels and automate reordering processes. This ensures that inventory is replenished only as needed. Such a proactive method optimizes operations and leads to substantial financial benefits.

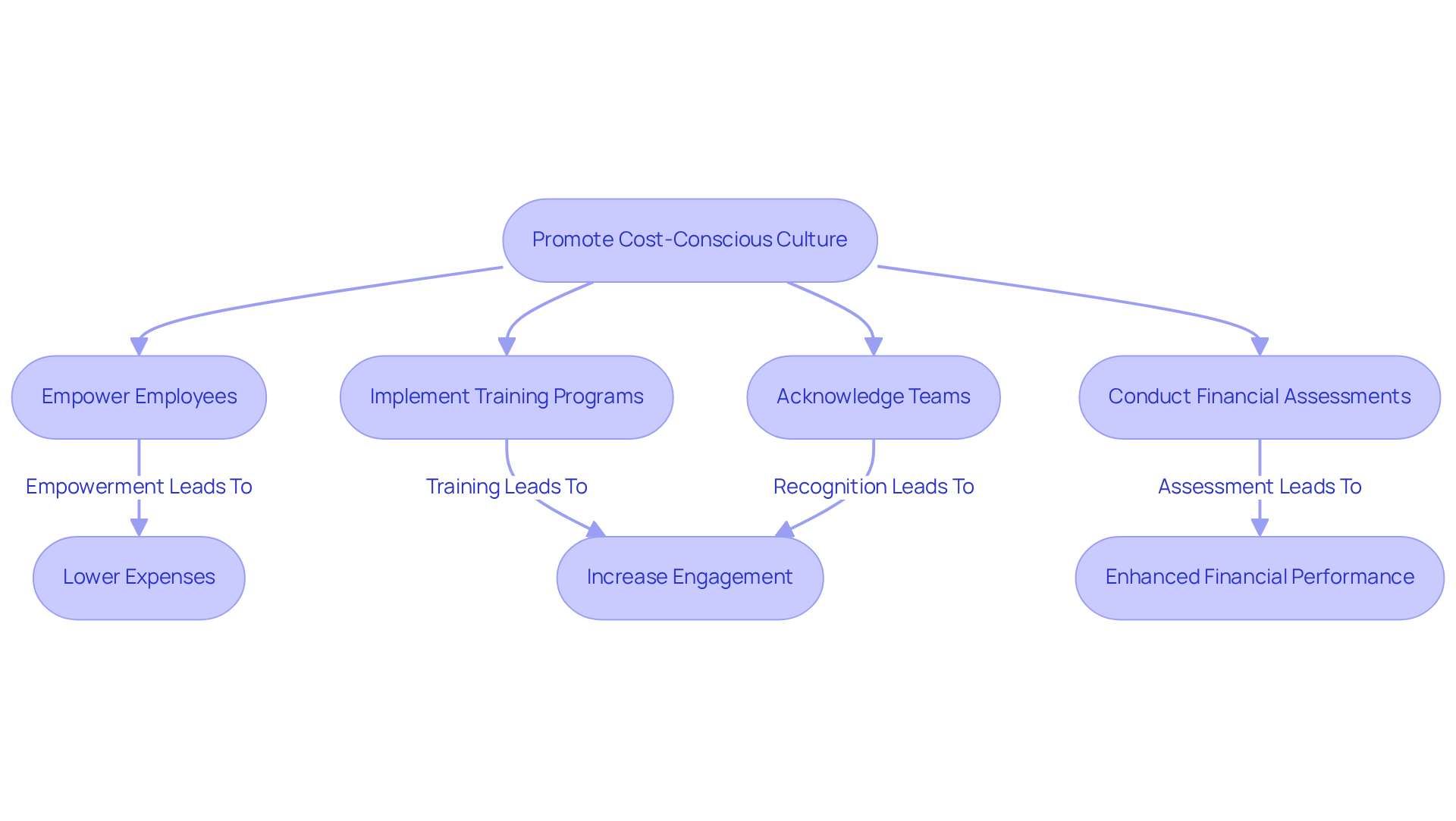

Promote a Cost-Conscious Culture: Foster Awareness and Accountability

Fostering a cost-conscious culture is essential for manufacturers to successfully implement cost reduction strategies and achieve sustainable savings within your organization. Empower employees to take ownership of their spending by encouraging them to identify areas for improvement. Implement extensive training programs that emphasize the importance of financial management, equipping staff with the skills to identify and respond to savings opportunities. Moreover, a thorough Financial Assessment can further enhance this initiative by identifying cost reduction strategies that preserve cash and reduce liabilities, providing a solid foundation for informed decision-making.

Acknowledging and rewarding teams that effectively lower expenses can enhance motivation and responsibility. Engaged staff can decrease turnover expenses by 33% of an employee's yearly salary. Establish clear cost-saving goals and monitor progress regularly. Commemorating milestones not only strengthens the significance of financial awareness but also nurtures a sense of collective responsibility among staff. Research indicates that organizations with high employee engagement can achieve a 21% higher productivity rate and experience a 25% lower turnover rate compared to those with low engagement, highlighting the potential for significant savings through cost reduction strategies.

By embedding these practices into your organizational culture, alongside comprehensive Financial Assessments focusing on cash preservation and efficiency, you can drive efficiency and enhance overall financial performance.

Conclusion

Implementing effective cost reduction strategies is essential for manufacturers aiming to enhance efficiency and ensure long-term sustainability. By focusing on comprehensive financial assessments, renegotiating vendor contracts, and embracing innovative technologies like e-procurement software, manufacturers can unlock significant savings and streamline their operations. These strategies not only emphasize the importance of identifying and eliminating unnecessary expenses but also highlight the potential for substantial cost savings across various facets of the manufacturing process.

Throughout this discussion, key insights such as the benefits of:

- Consolidating suppliers

- Automating accounting processes

- Fostering a cost-conscious culture

have been explored. Each strategy presents unique opportunities for manufacturers to optimize their operations and reduce overhead costs. By adopting a proactive approach to procurement, inventory management, and employee engagement, organizations can create a robust framework for financial efficiency and operational excellence.

Ultimately, the path to cost reduction transcends mere expense cutting; it involves fostering a mindset that values efficiency and accountability within the organization. By prioritizing these strategies, manufacturers can navigate the complexities of the market and position themselves for success in 2025 and beyond. Embracing a culture of continuous improvement and leveraging data-driven insights will empower businesses to not only survive but thrive in an increasingly competitive landscape.

Frequently Asked Questions

Why is a comprehensive financial assessment important for small to medium manufacturers?

A comprehensive financial assessment is essential as it involves an in-depth analysis of cash flow, expenses, and revenue streams, helping to identify underlying business issues, uncover inefficiencies, and highlight opportunities for savings.

How can historical monetary data aid in cost reduction for manufacturers?

Examining historical monetary data can reveal spending patterns that indicate unnecessary expenses, allowing businesses to strategically prioritize cost reduction strategies.

What role does vendor contract renegotiation play in cost reduction?

Renegotiating vendor contracts can lead to substantial reductions in supply chain management costs by identifying outdated terms, researching current market rates, and engaging in transparent discussions with vendors.

Can you provide an example of cost reduction achieved through contract renegotiation?

Firms have realized an initial cost reduction of 28.5% and a further cost prevention of 24.3% over two years through successful contract renegotiation, with one agricultural chemicals firm achieving $75 million in cost reductions.

What is the benefit of consolidating suppliers for manufacturers?

Consolidating suppliers reduces the number of vendors, streamlining procurement processes, facilitating bulk purchasing discounts, and fostering stronger relationships with key suppliers, ultimately resulting in cost efficiency.

How can real-time analytics enhance supplier management?

Incorporating real-time analytics allows procurement teams to monitor supplier performance continuously, make informed decisions quickly, and adapt strategies based on current data, improving overall procurement efficiency.

What is a supplier scorecard and how can it be used?

A supplier scorecard evaluates supplier performance based on criteria such as reliability, pricing, service quality, and shipping expenses, helping to determine which suppliers can be merged to improve procurement efficiency.

What financial benefits can organizations expect from effective supplier consolidation?

Organizations can attain purchasing expense reductions of 8-12% through effective supplier consolidation, highlighting the financial advantages of this strategy.