Overview

This article delves into best practices for cost reduction strategies within supply chains, specifically tailored for CFOs aiming to boost operational efficiency and profitability. It underscores the critical importance of optimizing inventory management, enhancing supplier negotiations, leveraging technology, and fostering a culture of continuous improvement. These essential tactics can lead to substantial savings and significantly enhance the financial health of organizations.

Moreover, by implementing these strategies, CFOs can not only streamline operations but also position their companies for sustainable growth. The focus on inventory management allows for better resource allocation, while improved supplier negotiations can yield more favorable terms and pricing. Additionally, leveraging technology facilitates data-driven decision-making, further driving efficiency.

Consequently, fostering a culture of continuous improvement encourages teams to innovate and adapt, ensuring that cost reduction is not merely a one-time effort but an ongoing commitment to excellence. By embracing these practices, organizations can achieve remarkable financial outcomes and reinforce their competitive edge in the market.

Introduction

In the competitive landscape of 2025, businesses are increasingly recognizing the critical importance of cost reduction within their supply chains. As market volatility intensifies, the pressure to streamline operations while curbing expenses has reached unprecedented levels. Effective cost reduction strategies not only bolster financial performance but also enhance overall supply chain efficiency, directly influencing cash flow and profitability.

With trends indicating longer delivery times and rising operational costs, organizations must adopt innovative approaches to:

- Optimize inventory management

- Improve supplier negotiations

- Leverage technology for smarter logistics

This article delves into the key strategies and best practices that CFOs can implement to navigate these challenges, foster a culture of continuous improvement, and ultimately drive sustainable growth in an ever-evolving business environment.

Understanding the Importance of Cost Reduction in Supply Chains

Implementing cost reduction strategies in the supply chain is essential for maintaining competitiveness and profitability in 2025. As businesses navigate a volatile market, the pressure to optimize operations has never been greater. Thus, implementing cost reduction strategies in the supply chain is crucial for minimizing expenses. Strategies such as the '20 Strategies for Optimal Business Performance' not only strengthen the bottom line but also enhance overall logistics efficiency, directly impacting the cash conversion cycle.

For CFOs, every dollar saved through these strategies translates into significant improvements in the company's financial health, facilitating reinvestment in growth initiatives and innovation. Recent trends indicate that the average time to deliver products from suppliers to customers has increased by 20% since 2020, underscoring the urgent need for strategic interventions. Key initiatives, such as optimizing inventory management through demand forecasting and Just-in-Time inventory systems, along with streamlining transportation by consolidating shipments, negotiating with carriers, and employing cost reduction strategies in the supply chain, are essential for achieving these savings. These optimized procedures and effective transportation represent critical components of cost reduction strategies, playing a major role in decreasing expenses and improving cash flow and profitability.

Moreover, a dedication to minimizing expenses fosters a culture of efficiency and responsibility within organizations, aligning all departments toward common financial goals. The significance of supplier diversity must also be acknowledged; it not only fosters economic expansion but also strengthens communities, further amplifying the social influence of expense-saving initiatives.

Case studies show that the container sector is presently undergoing a surge, with anticipated fleet growth expected to hit 5.1 million TEUs in 2023-24, 2.6 times greater than historical averages. However, this increase brings challenges in capacity management, highlighting the necessity for cost reduction strategies in the supply chain to effectively address potential inefficiencies. By prioritizing these strategies and leveraging real-time analytics for continuous performance monitoring, CFOs can ensure their organizations remain agile and responsive in an ever-evolving landscape.

To access these strategies, consider investing $99.00, which can significantly enhance your approach to mastering the cash conversion cycle.

Key Strategies for Effective Cost Reduction in Supply Chain Management

To effectively reduce costs in supply chain management, CFOs should consider the following strategies:

- Optimize Inventory Management: Implementing just-in-time inventory systems can significantly reduce holding expenses and minimize waste. Despite the potential benefits, only 22% of small businesses currently utilize inventory management software, indicating a substantial opportunity for improvement. By adopting advanced inventory management techniques, companies can enhance visibility and decision-making. Real-time analytics, as demonstrated by Netstock's new AI capabilities, empower small- and medium-sized businesses with actionable insights, allowing for better inventory control and strategic planning.

- Enhance Supplier Negotiations: Building strong relationships with suppliers is crucial for negotiating better terms and pricing. Companies that engage in mature supplier collaboration report 40% shorter lead times and 35% lower safety stock requirements, highlighting the efficiency gains that can be achieved through effective negotiation strategies. As Marijn Overvest, Founder of Procurement Tactics, states, "I have a deep passion for procurement, and I’ve upskilled over 200 procurement teams from all over the world." This underscores the significance of cultivating connections to attain substantial savings in procurement, backed by ongoing performance evaluation through real-time analytics.

- Streamline Transportation and Logistics: Examining transportation pathways and consolidating shipments can result in significant decreases in freight expenses. In 2024, 33% of U.S. small enterprises still encountered delivery delays due to persistent global disturbances, highlighting the critical necessity for effective logistics management. By utilizing real-time data, businesses can make informed decisions that enhance customer satisfaction and maintain sales.

- Leverage Automation: Utilizing technology to automate repetitive tasks can lead to substantial labor savings and enhanced accuracy. Automation not only streamlines operations but also allows teams to focus on strategic initiatives that drive growth. This approach supports a shortened decision-making cycle, enabling quicker responses to market changes.

- Implement Lean Practices: Embracing lean methodologies aids in removing waste and enhancing process efficiency throughout the logistics network. By consistently evaluating and improving processes, companies can attain sustainable savings while enhancing overall performance. The integration of real-time analytics into lean practices allows for ongoing adjustments and improvements, ensuring that businesses remain agile and responsive.

By incorporating these cost reduction strategies in supply chain management, CFOs can successfully navigate the complexities of logistics management and achieve significant savings, particularly in addressing the challenges faced by small to medium enterprises.

Leveraging Technology for Supply Chain Cost Optimization

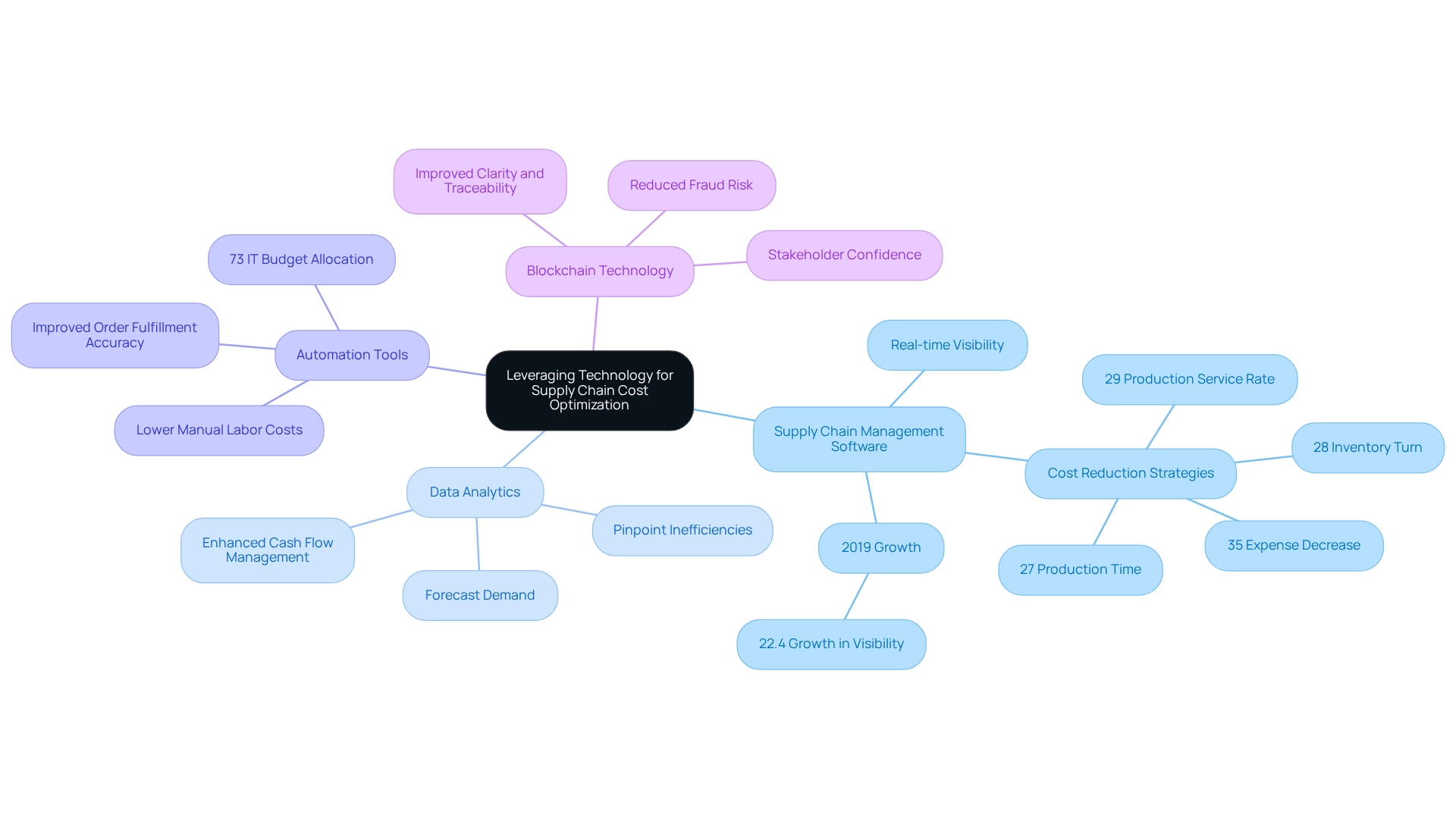

Technology is essential for optimizing supply chain costs, and CFOs should prioritize the following advancements to enhance efficiency and drive savings:

- Supply Chain Management Software: Adopting comprehensive software solutions is crucial for achieving real-time visibility into inventory levels, order statuses, and supplier performance. This clarity not only simplifies processes but also aids in making informed decisions, ultimately leading to effective cost reduction strategies in supply chain and resulting in substantial savings. In fact, organizations that adopted advanced visibility solutions for logistics experienced a remarkable 22.4% growth in 2019, underscoring the significance of transparency in preventing minor issues and improving customer service. Daily performance indicators for supply chain optimization emphasize that cost reduction strategies in supply chain lead to an expense decrease of 35%, a production service rate of 29%, an inventory turn of 28%, and a production time of 27%, highlighting the essential role of technology in achieving these metrics. Our team supports a shortened decision-making cycle throughout the turnaround process, allowing your team to take decisive action to preserve your business. Additionally, we work collaboratively to identify underlying business issues and create plans to mitigate weaknesses, ensuring a comprehensive approach to improvement.

- Data Analytics: Leveraging data analytics allows businesses to pinpoint inefficiencies and accurately forecast demand. By analyzing historical data and market trends, CFOs can develop cost reduction strategies in supply chain to make better decisions regarding resource allocation, ensuring that inventory levels align with actual demand. This proactive strategy can implement cost reduction strategies in supply chain, resulting in a decrease in surplus inventory expenses and enhanced cash flow management. We continually monitor the success of our plans through our client dashboard, which provides real-time business analytics to continually diagnose your business health. Our pragmatic approach to data testing ensures that we maximize returns on invested capital in both the short and long term.

- Automation Tools: Investing in automation tools for warehousing and logistics is one of the effective cost reduction strategies in supply chain, as it can significantly lower manual labor costs while enhancing accuracy in order fulfillment. Automation not only speeds up processes but also minimizes human error, leading to improved operational efficiency. As logistics leaders increasingly designate their IT budgets—73% in 2023, according to recent surveys—toward growth and performance enhancements, automation remains a key area of focus. Shanna Reynolds, a Program Assistant, notes that "applications are reviewed on an individual basis using a holistic approach," highlighting the importance of evaluating technology solutions comprehensively.

- Blockchain Technology: Investigating blockchain technology can offer improved clarity and traceability within the logistics network. By establishing an unchangeable record of transactions, blockchain diminishes the risk of fraud and mistakes, which can result in significant savings. The capacity to monitor products across the distribution network guarantees responsibility and nurtures confidence among stakeholders.

Integrating these technological innovations not only enhances logistics expenses but also positions organizations to implement cost reduction strategies in supply chain and achieve sustainable growth in a progressively competitive environment. Continuous business performance monitoring and relationship-building through real-time analytics are essential for operationalizing turnaround lessons and ensuring long-term success. By thoughtfully organizing solutions and assessing investment returns, companies can attain substantial enhancements in their logistics management.

Establishing a Culture of Continuous Improvement in Supply Chain Operations

Creating a culture of ongoing enhancement within logistics operations is vital for implementing cost reduction strategies in the supply chain. CFOs at Transform Your Small/Medium Business can foster this culture through several strategic initiatives:

- Encouraging Employee Involvement: Actively engage employees at all levels to identify inefficiencies and propose enhancements. This involvement not only empowers staff but also taps into their firsthand experience, leading to innovative solutions that can streamline operations.

- Regular Training and Development: Invest in ongoing training programs to equip staff with the latest skills and knowledge necessary for optimizing processes. A well-trained workforce is more adept at adjusting to changes and applying best practices, which are essential for implementing cost reduction strategies in the supply chain and ultimately improving efficiency in logistics.

- Setting Performance Metrics: Establish clear and measurable performance metrics to track progress and pinpoint areas needing improvement. By consistently assessing these metrics, organizations can make informed choices that promote ongoing improvement in logistics operations. The importance of prompt and precise logistics operations is underscored by the fact that 65% of customers would forsake a retailer after only two to three delayed deliveries.

- Feedback Loops: Implement robust feedback mechanisms to collect insights from both employees and customers. This approach allows organizations to respond swiftly to challenges and seize opportunities, reinforcing a culture of agility and responsiveness. The impact of late or inaccurate deliveries on customer loyalty highlights the need for effective feedback systems.

- Streamlined Decision-Making and Real-Time Analytics: Leverage real-time business analytics to monitor performance continuously. By utilizing a client dashboard that provides real-time insights, CFOs at Transform Your Small/Medium Business can make quicker, data-driven decisions that enhance operational efficiency and support turnaround strategies. This proactive strategy not only assists in assessing business wellbeing but also in implementing lessons acquired during the turnaround process.

The financial advantages of a proactive method to resource management are clear. Firms that have invested in sustainable resource initiatives have reported an average earnings increase of 23%. Furthermore, as organizations face challenges such as talent shortages and operational disruptions, fostering a culture of continuous improvement becomes not just beneficial but necessary for long-term success. The present investment environment, illustrated by the $6.3 million in ISEED funding revealed to aid U.S. manufacturing, further highlights the significance of improving logistical capabilities through workforce development.

Utilizing Data Analytics for Informed Supply Chain Decisions

Data analytics serves as a crucial tool for enhancing logistics management, enabling CFOs to implement effective cost reduction strategies. However, it is essential to recognize that despite the vast potential of big data, many organizations still lack the capabilities to fully capitalize on it. By harnessing the power of analytics, CFOs can:

- Streamline Decision-Making: Our team facilitates a shortened decision-making cycle throughout the turnaround process, empowering CFOs to take decisive actions that preserve their businesses. This agility is vital in today’s fast-paced environment, where timely decisions can significantly affect operational efficiency.

- Analyze Key Performance Indicators (KPIs): Regularly reviewing KPIs is fundamental for assessing logistical performance. This practice not only highlights areas needing improvement but also aligns operational goals with strategic objectives. In 2025, the focus on KPIs will be critical, as organizations increasingly rely on data-driven insights to enhance their logistics processes.

- Forecast Demand Accurately: Predictive analytics enables businesses to anticipate customer demand with greater precision. By leveraging historical data and market trends, firms can significantly reduce the risks associated with overproduction and excess inventory, ultimately leading to savings and improved cash flow.

- Evaluate Supplier Performance: Analyzing supplier data is essential for assessing reliability, quality, and cost-effectiveness. By applying robust assessment criteria, CFOs can make informed purchasing decisions that bolster logistics resilience and efficiency. This strategic approach not only mitigates risks but also fosters stronger supplier relationships.

- Optimize Transportation Routes: Utilizing analytics to determine the most efficient paths supports cost reduction strategies within the supply chain while enhancing delivery times. By analyzing real-time data, organizations can adapt to changing conditions, ensuring that logistics operations remain agile and responsive.

Integrating these data analytics strategies into logistics decision-making not only enhances operational efficiency but also equips businesses to effectively manage potential disruptions. For example, brick-and-mortar retailers have successfully adopted data-driven optimization techniques to manage inventory, improving sales performance and reducing out-of-stock situations. As the landscape of logistics management evolves, the ability to leverage data analysis will be a critical differentiator for companies pursuing sustainable growth.

Moreover, with the median yearly income of logistics managers at $79,400, the financial implications of efficient logistics management underscore the need for skilled professionals in this domain. As Shanna Reynolds aptly states, "Applications are reviewed on an individual basis using a holistic approach," which parallels the necessity for a comprehensive perspective in supply chain analytics.

Incorporating Sustainability into Cost Reduction Strategies

Sustainability and financial savings are not mutually exclusive; in fact, they can effectively enhance each other. CFOs should consider the following sustainable practices to enhance operational efficiency and drive down costs:

- Energy Efficiency Initiatives: Implementing energy-saving measures can lead to significant decreases in utility expenses. For instance, adopting energy-efficient technologies in shipping has demonstrated potential for substantial fuel savings, which is crucial given the volatility of fuel prices. A recent case study titled "Opportunities for Energy Efficiency in Shipping" highlighted that energy efficiency technologies could reduce fuel consumption in both new and existing vessels, presenting a timely opportunity for the shipping sector to enhance its cost-effectiveness. Moreover, the slower progress on energy efficiency results in higher energy consumption and CO emissions, making the urgency of adopting such measures even more critical. As Lucas Boehlé, lead author on energy efficiency, noted, "Tracking energy efficiency progress for all regions and countries" is essential for understanding and improving our impact.

- Sustainable Sourcing: Choosing suppliers that emphasize sustainable practices not only supports environmental objectives but can also result in savings. By cultivating partnerships with suppliers dedicated to sustainability, companies can improve their supply chain resilience and potentially reduce procurement expenses. This approach aligns with the growing trend of companies seeking to integrate sustainability into their core operations, which has been shown to improve overall financial performance through cost reduction strategies in the supply chain.

- Waste Minimization Initiatives: Creating thorough waste minimization initiatives can greatly lower disposal expenses. By employing cost reduction strategies in the supply chain to minimize waste in production and logistics, organizations can streamline operations and alleviate the financial burden associated with waste management. For instance, introducing a grey water recycling system can result in energy savings of roughly 35.7% and total operational savings of about 31.5% within a month, highlighting the financial advantages of waste minimization initiatives. This statistic underscores the importance of waste reduction as a viable example of cost reduction strategies in the supply chain.

- Circular Economy Practices: Investigating possibilities for recycling and reusing materials can significantly lessen the demand for new resources and the related expenses. Adopting circular economy principles not only preserves resources but also creates opportunities for innovation and savings. As businesses increasingly adopt these practices, they can expect to see improvements in both sustainability metrics and financial outcomes.

Furthermore, the recent training week organized by the International Energy Agency in Paris focused on promoting global advancements in energy efficiency, underscoring the increasing significance of these initiatives in distribution networks, especially in emerging and developing economies.

By incorporating cost reduction strategies in the supply chain into logistics management, CFOs can achieve notable savings while aiding broader environmental objectives, ultimately positioning their organizations for long-term success.

Implementing Best Practices for Sustainable Cost Reduction in Supply Chains

To effectively implement sustainable cost reduction strategies within supply chains, CFOs should consider the following best practices:

- Develop a Strategic Plan: Create a thorough plan that outlines specific expense minimization goals and the actionable steps necessary to accomplish them. This plan should align with both long-term strategic objectives and daily operational execution, ensuring that all elements of the logistics network are optimized for efficiency.

- Engage Stakeholders: Actively involve key stakeholders throughout the planning and implementation phases. This involvement is essential for obtaining support and nurturing a cooperative atmosphere, which can greatly improve the chances of successful savings initiatives. Research indicates that organizations that integrate procurement into various departments, such as IT, can uncover substantial savings opportunities, thereby improving overall operational efficiency. Laura Juliano from Boston Consulting Group emphasizes this point, noting that many organizations have experienced turnover in procurement roles, leading to inefficiencies. By involving procurement in IT spending, businesses can identify and capitalize on significant savings opportunities.

- Monitor and Adjust: Establish a framework for regularly reviewing progress against established goals. This ongoing assessment allows for timely adjustments to strategies, ensuring that the organization remains agile and responsive to changing circumstances within the supply chain. Utilizing real-time business analytics through the client dashboard provided by Transform Your Small/ Medium Business can facilitate this process, enabling CFOs to make informed decisions quickly and effectively. The shortened decision-making cycle supported by this dashboard allows for rapid responses to emerging challenges and opportunities.

- Communicate Successes: Promote a culture of continuous improvement by sharing successes and lessons learned across the organization. Emphasizing accomplishments not only strengthens the dedication to expense minimization but also fosters additional innovation and teamwork among groups. Establishing connections through open dialogue can improve the overall efficiency of budget-saving approaches.

As Joseph D'Souza, founder of ElectroIQ, states, 'Strategic planning is crucial for maneuvering through the intricacies of expense management in today's dynamic business environment.' By adopting these practices, CFOs can implement cost reduction strategies in supply chains that drive sustainable cost reductions, enhancing the resilience and profitability of their operations while leveraging streamlined decision-making and real-time analytics to monitor performance effectively.

Conclusion

In the face of escalating market volatility and rising operational costs, effective cost reduction within supply chains emerges as an essential strategy for businesses aiming to sustain competitiveness and profitability in 2025. This article has highlighted several key strategies that CFOs can implement to navigate the complexities of supply chain management, including:

- Optimizing inventory management

- Enhancing supplier negotiations

- Streamlining transportation logistics

- Leveraging technology

- Fostering a culture of continuous improvement

By focusing on innovative approaches such as just-in-time inventory systems and advanced data analytics, organizations can significantly reduce costs while enhancing operational efficiency. The integration of technology, including automation and blockchain, not only supports these initiatives but also positions companies for sustainable growth in an increasingly competitive landscape. Moreover, incorporating sustainability into cost reduction efforts reinforces the notion that economic and environmental goals can align, offering a pathway to both financial savings and social responsibility.

Ultimately, the commitment to continuous improvement and strategic planning is vital for achieving long-term success. By engaging employees, monitoring performance metrics, and fostering strong supplier relationships, businesses can create a resilient supply chain that not only withstands current challenges but also thrives in the future. As organizations embrace these best practices, they will be better equipped to navigate the evolving business environment, ensuring that cost reduction efforts contribute meaningfully to their overall success and sustainability.

Frequently Asked Questions

Why are cost reduction strategies important in supply chain management for 2025?

Cost reduction strategies are essential for maintaining competitiveness and profitability as businesses face a volatile market. They help minimize expenses, strengthen the bottom line, and enhance overall logistics efficiency.

What impact do cost reduction strategies have on a company's financial health?

Every dollar saved through cost reduction strategies improves a company's financial health, allowing for reinvestment in growth initiatives and innovation.

What recent trend has affected product delivery times?

The average time to deliver products from suppliers to customers has increased by 20% since 2020, highlighting the urgent need for strategic interventions in supply chain management.

What are some key initiatives for optimizing inventory management?

Key initiatives include demand forecasting and Just-in-Time inventory systems, which help manage inventory more effectively and reduce holding costs.

How can transportation costs be reduced in supply chain management?

Transportation costs can be reduced by consolidating shipments, negotiating better terms with carriers, and employing effective cost reduction strategies.

What cultural benefits arise from minimizing expenses in an organization?

A focus on minimizing expenses fosters a culture of efficiency and responsibility, aligning all departments toward common financial goals.

How does supplier diversity contribute to cost reduction strategies?

Supplier diversity fosters economic expansion and strengthens communities, thereby amplifying the social impact of expense-saving initiatives.

What challenges are currently faced by the container sector?

The container sector is experiencing a surge in fleet growth, which presents challenges in capacity management and highlights the need for effective cost reduction strategies to address potential inefficiencies.

What role do real-time analytics play in cost reduction strategies?

Real-time analytics allow for continuous performance monitoring, enabling CFOs to ensure their organizations remain agile and responsive to changes in the market.

What investment is suggested for accessing strategies to master the cash conversion cycle?

An investment of $99.00 is suggested to access strategies that can significantly enhance the approach to mastering the cash conversion cycle.