Overview

The article discusses best practices for inventory management strategies aimed at cost reduction, emphasizing the importance of accurate demand forecasting, technology adoption, and strong supplier relationships. These strategies are supported by evidence showing that effective inventory management not only reduces holding costs and improves cash flow but also enhances operational efficiency, positioning organizations for long-term success in a competitive market.

Introduction

In the realm of inventory management, the stakes have never been higher. As businesses strive to optimize their operations and reduce costs, effective inventory management emerges as a critical component for success. For CFOs, the challenge lies in striking the right balance between maintaining sufficient stock to meet customer demand and minimizing excess inventory that can drain resources.

With the e-commerce landscape rapidly evolving and consumer expectations shifting, organizations must adopt innovative strategies that harness:

- Data analytics

- Technology

- Strong supplier relationships

By focusing on continuous improvement and proactive decision-making, businesses can not only enhance their operational efficiency but also secure a competitive edge in an increasingly dynamic market. This article delves into proven strategies and actionable insights that empower organizations to master their inventory management and drive substantial cost reductions.

Understanding Inventory Management: A Key to Cost Reduction

Efficient inventory management strategies for cost reduction serve as a crucial foundation of operational achievement in the current competitive environment, especially for Chief Financial Officers (CFOs) focusing on expense reduction. It entails a thorough method for ordering, storing, and using stock, ensuring that businesses sustain the right balance of products to satisfy customer demand without incurring excessive expenses. This balance is emphasized by the fact that 49% of retailers monitor stock turnover as a crucial key performance indicator (KPI), directly associating it with profitability and operational success.

By strategically managing inventory levels and utilizing real-time analytics, organizations can adopt inventory management strategies for cost reduction, significantly reduce holding expenses, mitigate the risks associated with product obsolescence, and enhance their cash flow.

As we look towards 2025, e-commerce warehousing is poised to expand by 50%, responding to the escalating demand for online shopping. This evolving market landscape necessitates a shift towards ultra-personalization strategies, where technology enables real-time customer engagement and messaging. These strategies are essential for retailers navigating economic fluctuations, enabling organizations to adapt swiftly to changing consumer needs and preferences.

Moreover, the adoption of real-time information systems for order fulfillment is becoming increasingly prevalent, as illustrated by case studies on effective applications of analytics in logistics. This advancement empowers stakeholders with immediate data, enhancing operational efficiency and responsiveness. By incorporating efficient decision-making processes—enabled by our client dashboard for real-time analytics—with ongoing performance monitoring, companies can excel in the cash conversion cycle through various inventory management strategies for cost reduction, ultimately strengthening the principles of expense reduction and profitability.

Proven Strategies for Reducing Inventory Costs

To effectively reduce stock costs, organizations can implement various inventory management strategies for cost reduction that focus on enhanced demand forecasting. Accurate demand forecasting is crucial; leveraging historical sales data and current market trends enables businesses to predict customer needs with precision. In fact, 45% of consumers state that responsible sourcing is among the most crucial sustainability claims influencing their shopping behavior, emphasizing the importance of data-driven decision-making in stock management.

According to industry insights, 2024 will see a heightened focus on demand forecasting accuracy, with investments in reliable data being paramount. As one supply chain expert aptly stated,

Investing in data that you can rely on is key to crafting better demand plans and growing sales in tumultuous times.

Furthermore, implementing a Just-In-Time (JIT) stock system can significantly reduce excess supplies by aligning order arrivals with production schedules, thus optimizing cash flow.

Consistently analyzing stock turnover enables businesses to recognize slow-moving items, offering insights for informed choices concerning markdowns or promotions. A case study titled 'Value of High-Quality Data' illustrates the consequences of poor forecasting, emphasizing that brands must invest in reliable data sources to inform their strategies. Additionally, common pitfalls in demand planning, such as relying solely on backward-looking sales data without considering external factors, can hinder forecasting accuracy.

These strategic measures, such as implementing inventory management strategies for cost reduction, not only lead to substantial cost savings but also enhance overall operational efficiency, positioning organizations for long-term success.

Leveraging Technology for Efficient Inventory Management

Investing in inventory management software and automation tools is crucial for enhancing efficiency and accuracy as part of inventory management strategies for cost reduction. Our approach supports a shortened decision-making cycle, empowering your team to take decisive actions that preserve value. These technologies enable organizations to track stock levels in real-time, automate reordering processes, and generate comprehensive reports that drive strategic decision-making.

With advancements such as barcode scanning and RFID technology, companies can streamline operations, significantly reducing manual counting errors and accelerating stocktaking processes. Marijn Overvest, founder of Procurement Tactics, emphasizes the necessity of these technologies in today's market, where the Internet of Medical Things (IoMT) is rapidly evolving into a $160 billion industry, signaling the imperative for organizations to adopt innovative solutions. Furthermore, our client dashboard provides real-time business analytics, allowing for continuous monitoring of performance and the health of your operations, which is essential for the 'Update & Adjust' process.

This ongoing assessment enables your team to adapt strategies based on performance data, ensuring that your operations remain agile and responsive. The lead time standard for laggards in other sectors is at 73.4 days, highlighting the significance of effective stock control practices. Generally, stock control is overseen by stock supervisors or supply chain experts, who play a crucial role in applying these technologies.

By utilizing advancements in stock control software, companies can adopt inventory management strategies for cost reduction, achieving enhanced visibility into their stock and effectively reducing shortages and excess situations while lowering expenses related to stock oversight. Notably, organizations that utilize automated systems report enhanced operational efficiency, allowing them to stay ahead of demand shifts—a critical advantage, particularly given that only 22% of organizations currently maintain a proactive supply chain network. This statistic highlights the role of technology in promoting a proactive approach to stock oversight, allowing businesses to tackle issues before they intensify.

Harnessing the latest technology not only streamlines processes but also positions your organization to proactively tackle challenges, making it an essential strategy in today's competitive landscape.

Building Strong Supplier Relationships for Better Inventory Control

Cultivating and sustaining strong connections with suppliers is crucial for achieving effective stock management. A proactive approach to supplier relationship management not only fosters open communication but also facilitates collaboration that can significantly enhance negotiation outcomes. By utilizing these collaborations, organizations can gain insights into market trends and secure timely deliveries, which are essential for maintaining optimal stock levels.

Furthermore, robust supplier connections enable companies to take advantage of bulk purchasing discounts and adaptable ordering choices, effectively lowering overall expenses. In fact, 56% of supply chain leaders identify sourcing for low-volume builds as a significant barrier to innovation, highlighting the critical role that supplier relationships play in overcoming such challenges. For instance, companies that embrace a value-driven partnership model often find that suppliers can offer invaluable advice on managing stock levels and optimizing product assortments.

This is particularly important given that only 22% of organizations have a proactive supply chain network, a flaw that has been exposed by the pandemic. Investing in these relationships leads to more effective inventory management strategies for cost reduction, ultimately reducing expenses and improving operational efficiency. The case study titled 'The Future of Supplier Relationship Management: Embracing Change for Long-Term Success' illustrates how strategic partnerships can lead to innovation and expense reduction, highlighting the importance of inventory management strategies for cost reduction and strong supplier relationships.

As Steve Bennett, a Business Formation Expert, articulates,

With LLCBuddy, you're not just getting a tutorial; you're gaining a trustworthy partner for your entrepreneurial journey.

Likewise, the future of supplier relationship oversight highlights the importance of strategic alliances and inventory management strategies for cost reduction, which can result in innovation, expense reduction, and a competitive advantage.

Continuous Improvement: Monitoring and Adjusting Inventory Strategies

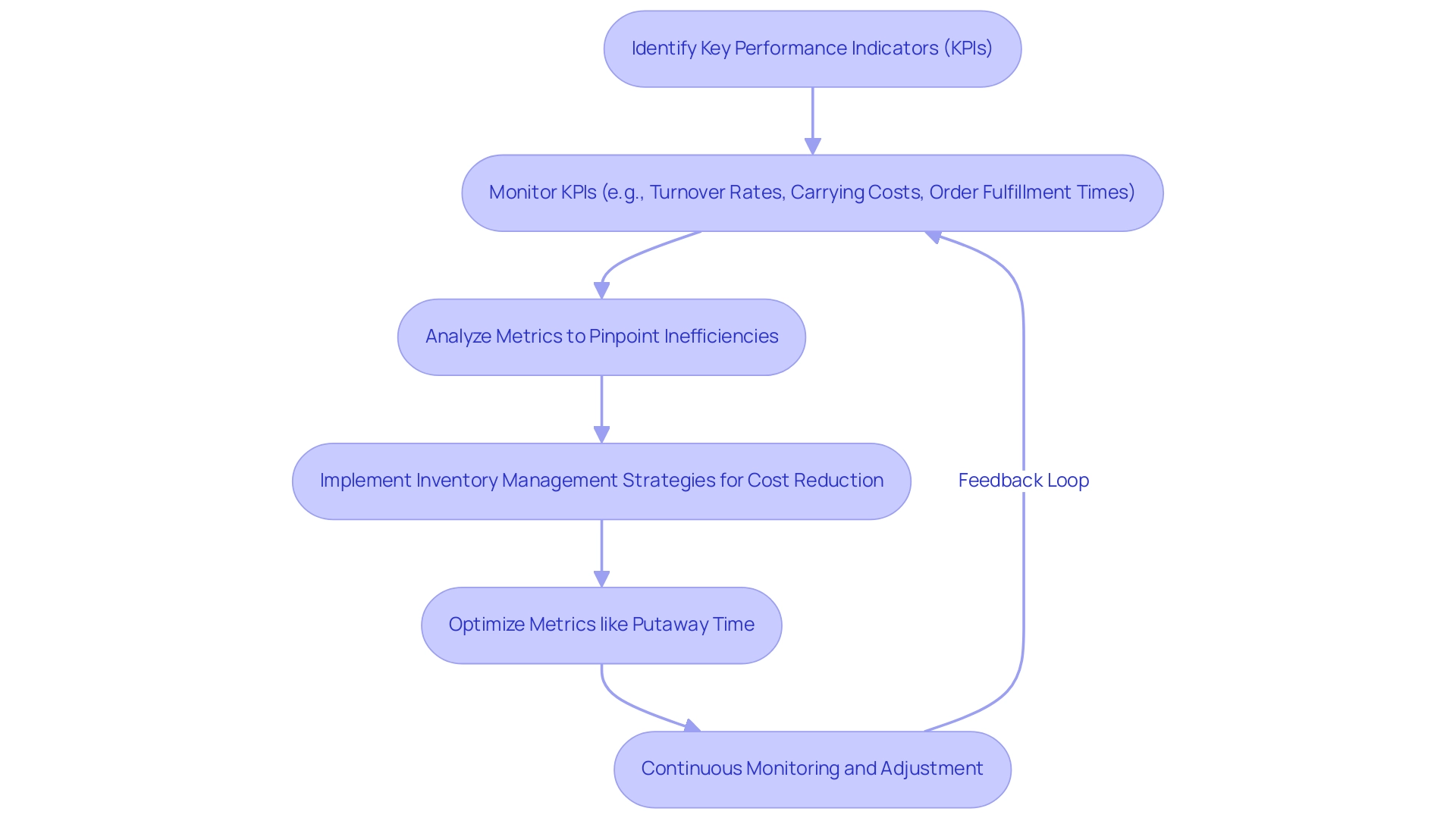

To attain sustainable savings in stock management, organizations must adopt a culture of ongoing enhancement. This commitment involves consistently monitoring key performance indicators (KPIs) such as:

- Turnover rates

- Carrying costs—which average 15% of total stock value annually

- Order fulfillment times

The considerable expense of holding stock highlights the necessity for implementing inventory management strategies for cost reduction that can directly improve overall financial results.

By thoroughly analyzing these metrics, companies can pinpoint inefficiencies and adapt their inventory management strategies for cost reduction accordingly. For instance, optimizing Putaway Time, which reflects the duration for moving goods from the receiving dock to storage, can significantly enhance order fulfillment speed and overall warehouse productivity. Continuous optimization of this metric not only improves efficiency but also aligns with inventory management strategies for cost reduction, contributing to long-term savings.

Additionally, utilizing tools like SkuNexus can simplify monitoring the Rate of Returns, providing insights into return reasons and helping organizations address root causes, which enhances customer satisfaction and further supports financial goals. As Robert McCarthy aptly states,

Let's get started on this journey to mastering your stock metrics!

This proactive approach not only bolsters operational efficiency but also enables businesses to respond swiftly to fluctuations in demand and market dynamics.

By fostering a mindset of continuous improvement, organizations ensure their inventory management strategies for cost reduction evolve in tandem with their operational goals, solidifying their long-term objectives.

Conclusion

Effective inventory management is essential for organizations seeking to reduce costs and enhance operational efficiency. By employing strategies such as:

- Accurate demand forecasting

- Just-In-Time inventory systems

- Leveraging technology

Businesses can optimize their inventory levels and significantly reduce excess stock. The importance of investing in reliable data cannot be overstated, as it underpins better decision-making and ultimately drives profitability.

Building strong supplier relationships further enhances inventory control. Proactive communication and collaboration with suppliers not only lead to timely deliveries but also unlock opportunities for cost savings through:

- Bulk purchasing

- Flexible ordering

The synergy created through these partnerships is critical for navigating market fluctuations and ensuring that inventory levels align with consumer demand.

Lastly, embracing a culture of continuous improvement is vital for long-term success. Regularly monitoring key performance indicators and adjusting inventory strategies in response to real-time data enables organizations to remain agile and responsive in a dynamic market environment. By committing to ongoing optimization, businesses can master their inventory management practices and achieve sustainable cost reductions, securing a competitive edge in an ever-evolving landscape.

Frequently Asked Questions

What are efficient inventory management strategies for cost reduction?

Efficient inventory management strategies for cost reduction involve a systematic approach to ordering, storing, and utilizing stock to maintain the right balance of products, satisfying customer demand while minimizing expenses.

Why is stock turnover important for retailers?

Stock turnover is crucial for retailers as 49% monitor it as a key performance indicator (KPI), linking it directly to profitability and operational success.

How can organizations reduce holding expenses through inventory management?

Organizations can reduce holding expenses by strategically managing inventory levels, utilizing real-time analytics, and mitigating risks related to product obsolescence, which enhances cash flow.

What is the significance of demand forecasting in inventory management?

Accurate demand forecasting is essential as it allows businesses to predict customer needs based on historical sales data and current market trends, which is vital for reducing stock costs.

What is the Just-In-Time (JIT) stock system?

The Just-In-Time (JIT) stock system aligns order arrivals with production schedules, significantly reducing excess supplies and optimizing cash flow.

How does real-time information systems impact order fulfillment?

Real-time information systems enhance operational efficiency by providing stakeholders with immediate data, improving responsiveness, and enabling better decision-making in inventory management.

What are common pitfalls in demand planning?

Common pitfalls in demand planning include relying solely on backward-looking sales data without considering external factors, which can hinder forecasting accuracy.

How can businesses recognize slow-moving items?

By consistently analyzing stock turnover, businesses can identify slow-moving items, allowing for informed decisions regarding markdowns or promotions.

What is the expected trend for demand forecasting in 2024?

In 2024, there will be a heightened focus on demand forecasting accuracy, with significant investments in reliable data being crucial for crafting effective demand plans.