Introduction

In the ever-evolving landscape of logistics, the ability to effectively track shipments and resources is paramount for organizations aiming to enhance operational efficiency and customer satisfaction. As the global logistics market continues to grow, CFOs face the pressing need to adopt advanced tracking systems that not only streamline processes but also provide real-time insights into performance metrics.

By leveraging cutting-edge technology and implementing best practices, businesses can navigate the complexities of modern logistics with agility and precision. This article delves into the fundamentals of logistics tracking, outlines effective strategies for improvement, and highlights the critical role of technology in driving successful turnaround management.

With actionable insights and data-driven approaches, CFOs are empowered to make informed decisions that safeguard their organizations' integrity and foster long-term success.

Understanding the Fundamentals of Logistics Tracking

Logistics monitoring serves as the backbone of effective logistics turnaround management, empowering organizations to oversee the movement of goods and resources in real-time. By adopting robust monitoring systems, companies can pinpoint inefficiencies, minimize delays, and significantly enhance customer satisfaction. A critical element of successful supply chain tracking is the establishment of clear performance metrics, coupled with precise data collection methods.

Furthermore, leveraging cutting-edge technology for real-time visibility is essential in streamlining decision-making processes. Our team supports a shortened decision-making cycle throughout the turnaround process, allowing CFOs to take decisive action that preserves business integrity. As the global shipping market is projected to grow by 4% by the end of 2023, CFOs must adapt to these dynamics, especially given that Asia accounts for approximately 40% of global road freight volumes, with China, Japan, and South Korea leading the charge.

Notably, industry experts highlight that the growth of the global logistics market is only slowly increasing due to the lingering after-effects of the COVID-19 pandemic. The anticipated annual growth of multimodal freight shipments by 4.6% until 2045 indicates a strategic shift towards integrated transport solutions, driven by evolving global supply chain demands. Ongoing performance monitoring via our client dashboard, which offers real-time analytics, enables organizations to assess their health effectively and modify strategies as necessary based on these insights.

The dashboard provides a variety of analytics, including monitoring shipment efficiency, delivery timelines, and customer feedback, enabling CFOs to make informed decisions. This is further supported by the case study on the growth of multimodal freight shipments, underscoring the importance of integrated transport solutions in meeting these demands. Additionally, a survey by Deliver reveals that 60% of businesses in the US engage in multi-channel marketing practices, which can bolster revenue by 21% in 2023.

Such statistics emphasize the necessity for CFOs to prioritize logistics turnaround management and data-informed decision-making to improve operational efficiency and customer satisfaction amid ongoing challenges.

Best Practices for Effective Logistics Tracking

- Leverage Advanced Tracking Software: Selecting logistics software equipped with real-time tracking and analytics capabilities is crucial. This enables organizations to proactively identify and resolve issues before they escalate, ultimately enhancing operational efficiency. Our team supports a shortened decision-making cycle throughout the logistics turnaround management process, allowing your team to take decisive action to preserve your business. The adoption rate of logistics software is expected to increase considerably in 2024, indicating the industry's transition towards more advanced monitoring solutions. Significantly, the rise from 68 to more than 200 SiMs daily demonstrates the growing complexity and importance of monitoring software in logistics.

- Standardize Monitoring Processes: Establishing standardized procedures for monitoring shipments is essential for ensuring consistency and reliability across operations. This approach not only streamlines processes but also minimizes the risk of errors, enabling a more resilient logistics framework. Our client dashboard offers real-time analytics to continually assess your company's health, emphasizing the need for strong monitoring processes. As highlighted by experts, the backlog of unresolved low-severity vulnerabilities could lead to greater security risks as these issues accumulate over time. Implementing standardized monitoring processes directly helps in preserving your enterprise by enhancing reliability and reducing operational disruptions.

- Train Employees on Best Practices: Regular training sessions focused on the effective use of monitoring systems can dramatically enhance accuracy and efficiency. Enabling personnel with the knowledge and skills to use these tools guarantees that companies can optimize their software's capabilities, thus aiding business preservation efforts.

- Integrate with Supply Chain Partners: To achieve a comprehensive view of logistics performance, it is vital to combine monitoring systems with those of suppliers and distributors. This collaboration facilitates seamless data sharing and communication, allowing organizations to respond swiftly to any disruptions in the supply chain. The SolarWinds attack in late 2020 serves as a stark reminder of how vulnerabilities within the supply chain can have widespread impacts, emphasizing the necessity for robust tracking systems to mitigate such risks.

- Monitor and Adapt: Continuously observing operational processes and being open to adjusting strategies based on performance data and feedback is essential. This iterative method guarantees that entities stay flexible and able to manage the intricacies of contemporary supply chain processes. By consistently tracking the effectiveness of our strategies through real-time analytics offered by our client dashboard, companies can implement turnaround lessons efficiently, thus maintaining business integrity.

Adopting these best practices will enable firms to establish a flexible supply chain framework, which is crucial for effective logistics turnaround management. In light of recent incidents, such as the SolarWinds attack, it has become clear that robust tracking processes are not just beneficial but necessary to safeguard against vulnerabilities in the supply chain.

Developing a Comprehensive Logistics Strategy

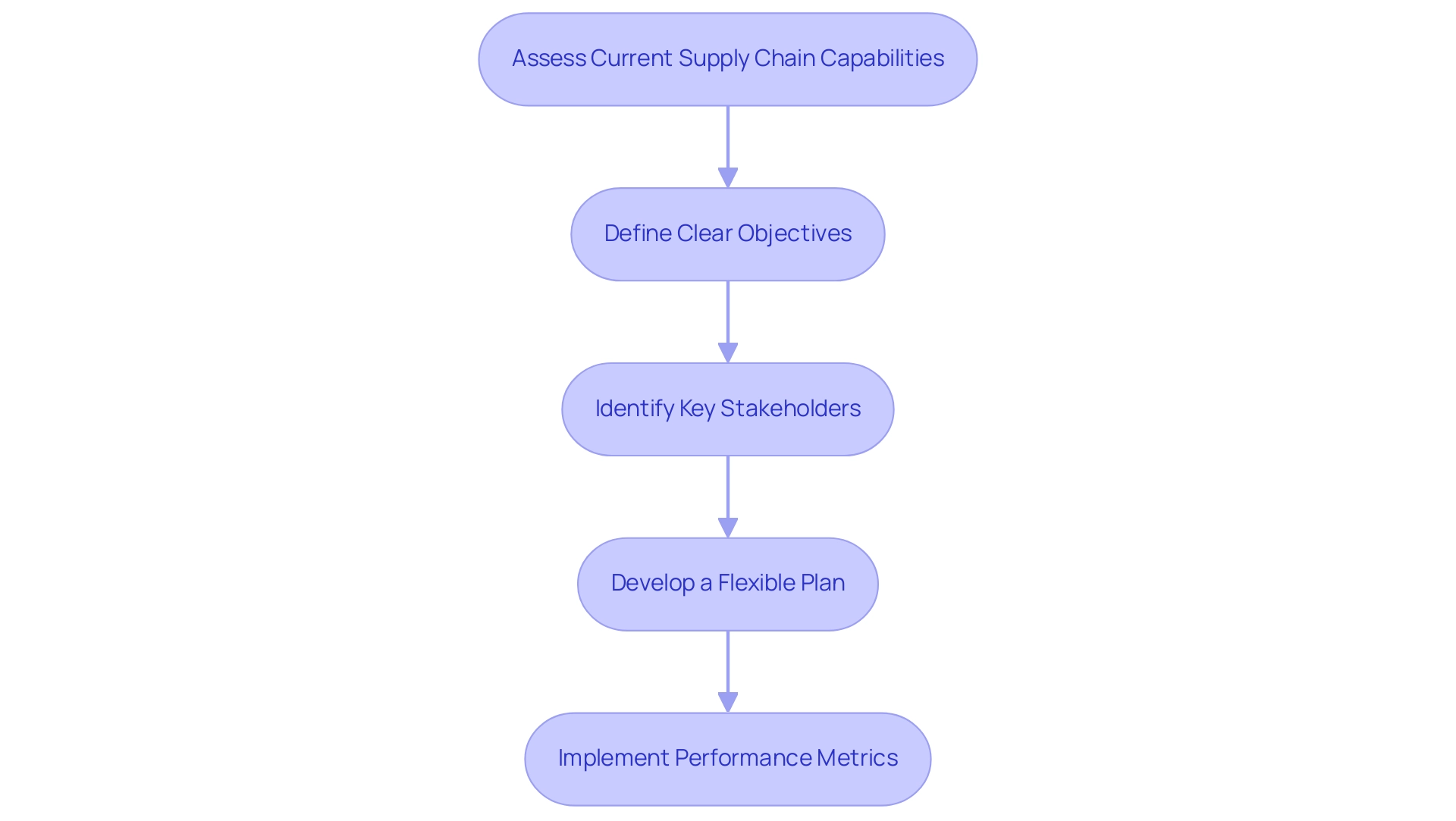

To create a thorough supply chain strategy that enhances turnaround management and positions firms for lasting success, CFOs should follow these crucial steps:

-

Assess Current Supply Chain Capabilities:

Initiate a detailed evaluation of existing supply chain processes to pinpoint strengths and weaknesses. With 64% of entities experiencing logistical consequences, this assessment is crucial for identifying areas needing improvement.

-

Define Clear Objectives:

Establish supply chain goals that are in harmony with overarching business objectives, ensuring that these efforts bolster the organization’s turnaround vision.

-

Identify Key Stakeholders:

Actively engage with vital stakeholders, including suppliers and customers, to gain insights into their needs and expectations. This engagement will guide strategic decisions and foster collaboration. As noted by industry leaders, 'Effective stakeholder engagement is critical for successful supply chain strategy development.'

-

Develop a Flexible Plan:

Formulate a transportation strategy that remains adaptable to evolving market conditions, allowing for swift pivots as required during the turnaround phase. This flexibility is crucial in today’s dynamic environment, where 79% of Chief Supply Chain Officers are investing in training programs to incorporate advanced analytics into their operations.

For instance, Asia, representing around 40% of global road freight volumes, illustrates the significance of a strong supply chain strategy amid rapid economic growth.

-

Implement Performance Metrics:

Create and monitor key performance indicators (KPIs) to evaluate supply chain performance continually.

Utilizing data-driven adjustments will ensure the strategy remains effective and aligned with business objectives.

By utilizing comprehensive turnaround consulting services, including interim management, financial assessment, and bankruptcy case management, companies can develop a strategy that not only enhances turnaround initiatives but also establishes a foundation for long-term operational excellence. Marijn Overvest, founder of Procurement Tactics and trainer of over 200 procurement teams worldwide, stresses the necessity for a strategic approach in supply chain management to meet the demands of a rapidly changing market.

Leveraging Technology for Enhanced Turnaround Management

-

Adopt Cloud-Based Logistics Solutions: Leveraging cloud technology enables organizations to access real-time data and enhance collaboration across teams, crucial for streamlined decision-making and a shortened decision-making cycle. This immediate access to information fosters better responsiveness in an increasingly dynamic market. With the small and medium enterprises segment projected to grow rapidly, demand for cost-effective and scalable logistics solutions makes cloud adoption pivotal. Google Cloud’s IaaS offering, for example, has seen a remarkable growth rate of 63.7%, indicating strong market performance and positioning it as a competitive player in the IaaS market.

-

Implement IoT Devices: The integration of Internet of Things (IoT) devices facilitates real-time tracking of shipments and inventory, significantly reducing losses while optimizing supply chain performance. This capability empowers organizations to respond swiftly to disruptions, enhancing operational resilience and supporting continuous performance monitoring.

Utilize Data Analytics: By employing advanced data analytics tools, organizations can extract valuable insights into operational performance and customer behaviors. This analytical capability not only aids in making more informed strategic decisions but also enables organizations to implement lessons learned, aligning supply chain strategies effectively with market demands. A client dashboard can be utilized to monitor these analytics in real time, ensuring ongoing assessment of business health.

-

Explore Automation: Automating repetitive tasks in the supply chain, such as order processing and inventory management, can greatly improve efficiency and reduce the likelihood of errors. Implementing automation technologies streamlines operations, enabling quicker decision-making and freeing up resources to focus on strategic initiatives.

-

Invest in Cybersecurity: As dependence on technology in supply chain management deepens, investing in robust cybersecurity measures becomes essential. Protecting sensitive data from breaches—an issue highlighted as a leading cause of cloud-based data breaches—ensures operational integrity and builds customer trust. Misconfiguration of cloud services, the leading cause of such breaches, underscores the need for vigilance in cybersecurity practices.

Embracing these technological advancements is crucial for enhancing logistics turnaround management. By implementing these strategies, organizations can achieve significant improvements in performance, responsiveness, and ultimately, successful turnaround outcomes. Additionally, a pragmatic approach to data involves testing hypotheses to maximize return on invested capital, ensuring that strategies are effective and aligned with organizational goals.

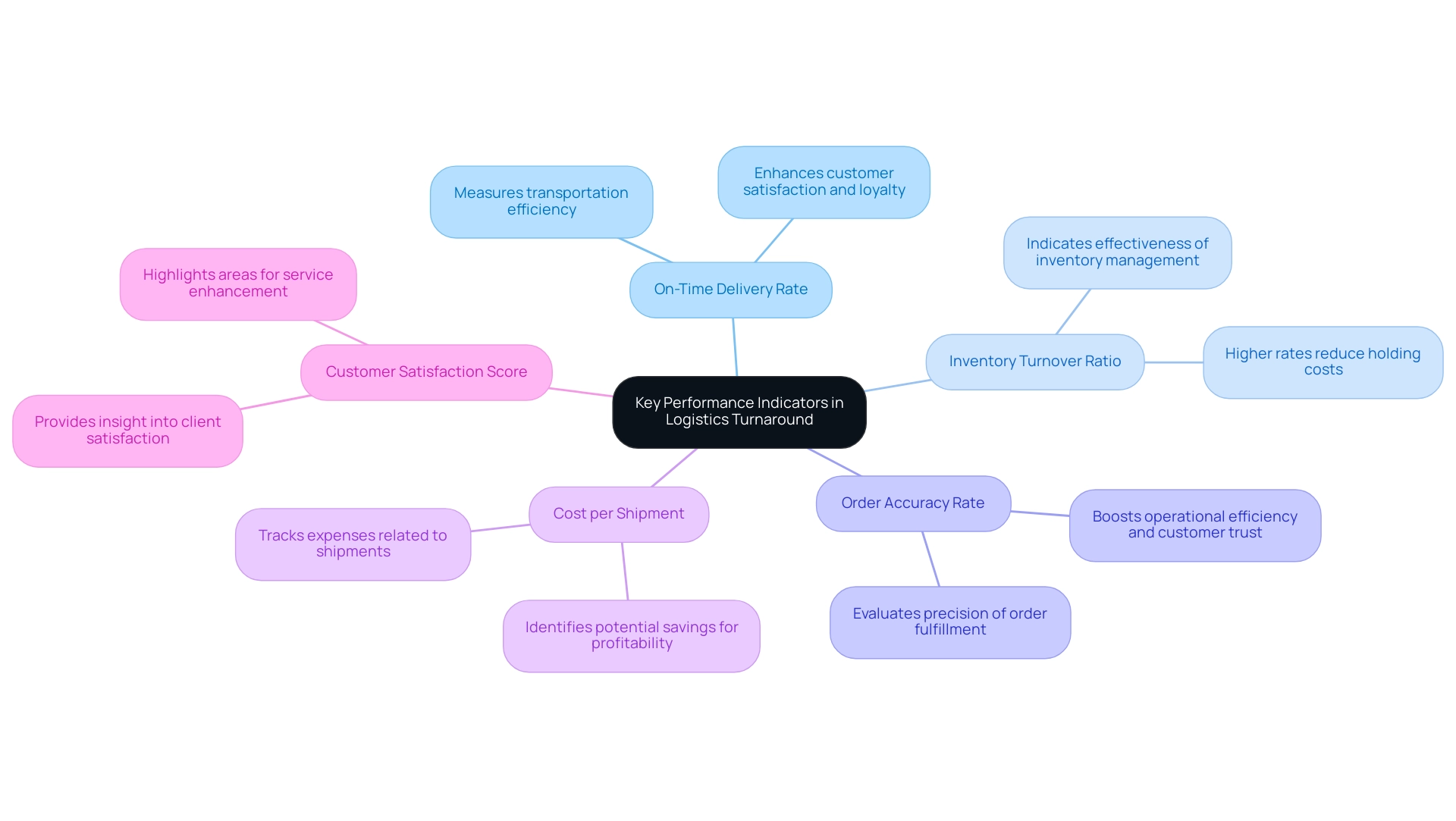

Measuring Success: Key Performance Indicators in Logistics Turnaround

Key Performance Indicators (KPIs) serve as essential tools for assessing the success of logistics turnaround management initiatives in the supply chain, particularly in the context of streamlined decision-making and real-time analytics. To effectively gauge performance and operationalize turnaround lessons, consider the following critical KPIs:

-

On-Time Delivery Rate: This measures the percentage of shipments delivered punctually, providing a direct assessment of transportation efficiency.

An emphasis on improving this metric is crucial, especially given that timely deliveries significantly enhance customer satisfaction and loyalty.

-

Inventory Turnover Ratio: This ratio reveals how frequently inventory is sold and replenished within a specific timeframe, indicating the effectiveness of inventory management practices.

Higher turnover rates typically correlate with reduced holding costs and improved cash flow.

-

Order Accuracy Rate: Evaluating the precision of order fulfillment helps identify areas for improvement, directly impacting customer satisfaction.

Striving for higher accuracy not only boosts operational efficiency but also strengthens customer trust.

-

Cost per Shipment: Tracking the expenses related to each shipment enables organizations to evaluate overall transportation cost efficiency.

Identifying potential savings in this area can significantly enhance profitability while maintaining service quality.

-

Customer Satisfaction Score: Regularly obtaining feedback from clients provides insight into their satisfaction with delivery services, highlighting areas that require enhancement.

High customer satisfaction scores are indicative of successful supply chain operations and foster long-term relationships.

In light of the increasing cybersecurity threats facing the supply chain industry—56% of companies in this sector reported a data breach last year and a staggering 715% rise in ransomware attacks in 2020—tracking these KPIs becomes even more critical. By consistently tracking these metrics through our client dashboard, organizations can not only pinpoint successes and identify opportunities for improvement but also mitigate risks associated with operational activities.

The client dashboard provides real-time business analytics that allow for a shortened decision-making cycle, enabling your team to take decisive actions swiftly. As Kam Kendell of Northern Express Logistics states,

After implementing Upper Route Planner, we automated route planning and optimized delivery windows, resulting in a 92% reduction in manual planning efforts and a 3x increase in daily deliveries.

This illustrates the tangible benefits of leveraging KPIs to drive operational excellence and address the challenges posed by a volatile logistics landscape through effective logistics turnaround management.

Conclusion

In the realm of logistics, effective tracking is not just a necessity; it is a strategic imperative that can significantly enhance operational efficiency and customer satisfaction. By understanding the fundamentals of logistics tracking, businesses can identify inefficiencies and minimize delays, setting the stage for robust turnaround management. The article underscores the importance of adopting advanced tracking systems, standardizing processes, and continuously monitoring performance to ensure organizations remain agile in a rapidly changing market.

Implementing best practices such as leveraging advanced tracking software, training employees, and integrating with supply chain partners are essential steps that CFOs must prioritize. These strategies foster a resilient logistics framework that is capable of adapting to evolving demands. Furthermore, the integration of technology—such as cloud-based solutions, IoT devices, and advanced data analytics—empowers organizations to operate with unprecedented visibility and responsiveness.

Ultimately, the success of logistics initiatives hinges on the establishment and monitoring of key performance indicators. By focusing on metrics like on-time delivery rates and customer satisfaction scores, organizations can measure their effectiveness and make informed adjustments to their strategies. As the logistics landscape continues to evolve, embracing these insights and technological advancements will be critical for organizations striving for long-term success and operational excellence in a competitive environment.

Frequently Asked Questions

What is the role of logistics monitoring in turnaround management?

Logistics monitoring serves as the backbone of effective logistics turnaround management, allowing organizations to oversee the movement of goods and resources in real-time, pinpoint inefficiencies, minimize delays, and enhance customer satisfaction.

How can companies improve their logistics monitoring systems?

Companies can improve their logistics monitoring systems by adopting robust monitoring solutions, establishing clear performance metrics, and implementing precise data collection methods.

Why is real-time visibility important in logistics?

Real-time visibility is essential in logistics as it streamlines decision-making processes, enabling CFOs to take decisive actions that preserve business integrity and adapt to market dynamics.

What is the projected growth of the global shipping market by the end of 2023?

The global shipping market is projected to grow by 4% by the end of 2023, with Asia accounting for approximately 40% of global road freight volumes.

How has the COVID-19 pandemic affected the logistics market?

The growth of the global logistics market is slowly increasing due to the lingering after-effects of the COVID-19 pandemic.

What is the anticipated growth rate for multimodal freight shipments until 2045?

The anticipated annual growth rate for multimodal freight shipments is 4.6% until 2045, indicating a strategic shift towards integrated transport solutions.

What features does the client dashboard provide for performance monitoring?

The client dashboard offers real-time analytics to monitor shipment efficiency, delivery timelines, and customer feedback, enabling informed decision-making for CFOs.

What percentage of businesses in the US engage in multi-channel marketing practices?

According to a survey by Deliver, 60% of businesses in the US engage in multi-channel marketing practices, which can boost revenue by 21% in 2023.

What best practices can organizations adopt for effective logistics turnaround management?

Organizations can adopt best practices such as leveraging advanced tracking software, standardizing monitoring processes, training employees, integrating with supply chain partners, and continuously monitoring and adapting strategies.

Why is training employees on monitoring systems important?

Regular training on monitoring systems enhances accuracy and efficiency, enabling employees to optimize the software's capabilities, which aids in business preservation efforts.

How can integrating with supply chain partners improve logistics performance?

Integrating monitoring systems with those of suppliers and distributors allows for seamless data sharing and communication, enabling organizations to respond swiftly to disruptions in the supply chain.

What should companies do to maintain flexibility in their supply chain processes?

Companies should continuously observe operational processes and be open to adjusting strategies based on performance data and feedback to maintain flexibility in managing contemporary supply chain complexities.