Overview

This article examines engineering cost reduction strategies that CFOs can implement to enhance organizational efficiency. It underscores the critical need to integrate financial assessments with engineering principles. Techniques such as:

- Lean manufacturing

- Design-to-expense

- Cross-functional collaboration

are highlighted as essential methods for identifying savings opportunities and improving overall project outcomes. By leveraging these strategies, CFOs can drive significant improvements in both cost management and project success.

Introduction

In the intricate realm of project management, cost engineering stands out as a crucial discipline that integrates engineering principles with business acumen to optimize project expenditures. As organizations endeavor to sustain financial health in the face of fluctuating economic conditions, grasping the essentials of cost estimation, control, and value engineering becomes imperative. This article explores effective techniques and strategies that CFOs can implement to enhance efficiency and drive cost reductions, ensuring projects are completed not only on time but also within budget.

Moreover, fostering cross-functional collaboration and implementing lifecycle cost analysis are pivotal steps toward sustainable growth. The journey is marked by informed decision-making and continuous improvement. With the right skills and strategies in place, organizations can adeptly navigate the complexities of cost management, emerging resilient against financial challenges.

Understand Cost Engineering Fundamentals

Cost management represents the strategic application of engineering principles intertwined with business acumen, aimed at effectively overseeing expenses through engineering cost reduction strategies. The key components of this discipline include:

- Cost Estimation: Accurately forecasting project expenses is vital for effective budgeting and financial planning. In 2025, the significance of precise expense assessment in management cannot be overstated, as it directly influences success and resource allocation.

- Expense Management: This entails the organized application of strategies to oversee and regulate expenses throughout the initiative lifecycle, thereby preventing budget overruns. Efficient expense management systems are essential for sustaining financial stability and ensuring initiative viability.

Value engineering focuses on evaluating the functions of a project to enhance value while simultaneously applying engineering cost reduction strategies. By ensuring that projects adhere to both quality standards and budgetary constraints, value engineering is instrumental in optimizing project outcomes.

In addition to these fundamentals, a comprehensive monetary evaluation is crucial for identifying opportunities to conserve cash and reduce liabilities. By collaborating with financial specialists, CFOs can uncover value and mitigate risks, ensuring that their organizations remain resilient in challenging economic landscapes. As Martin Luther King Jr. stated, "The ultimate measure of a man is not where he stands in moments of comfort and convenience, but where he stands at times of challenge and controversy."

This quote resonates with CFOs who must navigate the complexities of expenditure management during difficult economic periods.

By mastering these fundamentals and integrating thorough financial reviews, CFOs can effectively align engineering initiatives with their financial objectives, ensuring that engineering cost reduction strategies are implemented to complete projects not only on schedule but also within budgetary constraints. In a landscape where 11.5k motivational quotes exist, the insights derived from these can drive efficient financial management strategies. Furthermore, recognizing that perception resembles an oscillator circuit—where truth fluctuates based on awareness and ignorance—can significantly influence CFOs' decision-making processes.

This alignment is increasingly vital in today's dynamic business landscape, where efficiency is paramount and current trends in engineering for 2025 continue to evolve.

Explore Effective Cost Engineering Techniques

To enhance efficiency and drive down costs, several effective engineering techniques can be implemented:

- Lean Manufacturing: This methodology emphasizes the elimination of waste while maintaining productivity. By adopting lean principles, organizations can implement engineering cost reduction strategies that lead to substantial savings. This approach fosters a culture of continuous improvement and operational excellence. Implementing these strategies helps organizations reduce waste, enhance quality, and achieve sustainable success. Statistics indicate that it typically takes 2 to 3 years for companies to fully integrate these practices, reflecting the commitment required for long-term success. As Niharika Chaurasia observes, this timeline underscores the dedication necessary for successful execution.

- Design-to-Expense (DTE): This method integrates financial considerations into the product design phase, ensuring development remains within budget limits. Effective DTE strategies have shown the ability to improve project budgeting results by implementing engineering cost reduction strategies, leading to more efficient resource distribution and decreased financial risk.

- Benchmarking: By contrasting project expenses against industry benchmarks, organizations can identify inefficiencies and adopt best practices through engineering cost reduction strategies. This method not only emphasizes areas for enhancement but also promotes a competitive attitude that drives innovation and efficiency.

- Automation: Utilizing technology to automate processes can significantly lower labor expenses and contribute to engineering cost reduction strategies while improving precision in expense estimation. Automation streamlines operations, allowing teams to focus on strategic initiatives rather than routine tasks.

Additionally, a case study comparing lean manufacturing with traditional manufacturing methods illustrates how lean practices promote higher productivity, quality, and competitiveness by prioritizing efficiency and employee engagement. Applying these methods enables CFOs to cultivate a culture of financial awareness and ongoing enhancement, ultimately positioning their organizations for improved competitiveness through engineering cost reduction strategies and sustainable growth. The journey of lean manufacturing reflects continuous innovation and adaptation to changing economic and technological landscapes.

Implement Engineering-Led Cost Reduction Approaches

CFOs can implement various engineering-driven expense reduction strategies to improve efficiency and generate savings:

- Cross-Functional Collaboration: Encouraging cooperation among engineering, finance, and operations teams is essential for recognizing savings opportunities early in the initiative lifecycle. This collaboration not only simplifies procedures but also brings together various viewpoints towards shared financial objectives, ultimately resulting in substantial savings. The essence of teamwork resides in the combined effort to reach shared objectives, which is crucial in this context.

- Lifecycle Expense Analysis: Implementing lifecycle expense analysis enables organizations to assess the total expenditure of ownership for products and projects. This method takes into account not just initial acquisition expenses but also continuous maintenance and operational expenditures, offering a thorough perspective that can reveal hidden savings through engineering cost reduction strategies. Understanding customer bases is essential; as Jeff Bezos stated, 'If your customer base is aging with you, then eventually you are going to become obsolete or irrelevant.' This underscores the significance of remaining pertinent in expense management strategies.

- Supplier Relationship Management: Developing robust connections with suppliers can result in improved negotiation results and bulk purchasing opportunities, which can greatly reduce expenses. By working closely with suppliers, companies can explore innovative engineering cost reduction strategies that enhance value and decrease expenses.

- Continuous Improvement Programs: Establishing continuous improvement programs that incorporate engineering cost reduction strategies encourages regular evaluation and enhancement of processes. This proactive approach helps identify inefficiencies and implement engineering cost reduction strategies, leading to sustained cost reductions over time. As Debasish Mridha wisely noted, 'Persistence, perseverance, and continuous improvement are the ingredients for forming a successful person.' This mindset is vital for organizations pursuing sustainable success.

- Streamlined Decision-Making and Real-Time Analytics: Our team facilitates a reduced decision-making cycle during the turnaround process, enabling your team to take decisive action to safeguard your enterprise. By continually monitoring the success of our plans through real-time business analytics, we can diagnose your business health effectively and make necessary adjustments promptly. This aligns with our 'Identify & Plan' approach, ensuring that we are always prepared to adapt to changing circumstances.

- Importance of Thorough Assessments of Finances: A comprehensive review can help identify opportunities to preserve cash and reduce liabilities. This assessment is critical for uncovering value and mitigating risks, ensuring that organizations can operate efficiently and effectively. By utilizing a 'Test & Measure' approach, we can confirm our economic assumptions and ensure that our reduction efforts are yielding the desired outcomes.

These strategies not only contribute to savings but also improve overall quality and performance, positioning organizations for long-term success. The case study titled 'CEO Alpha: Tailored Leadership for PE Success' illustrates how effective leadership and collaboration can drive superior returns through strategic talent management and performance tracking, ultimately safeguarding long-term success.

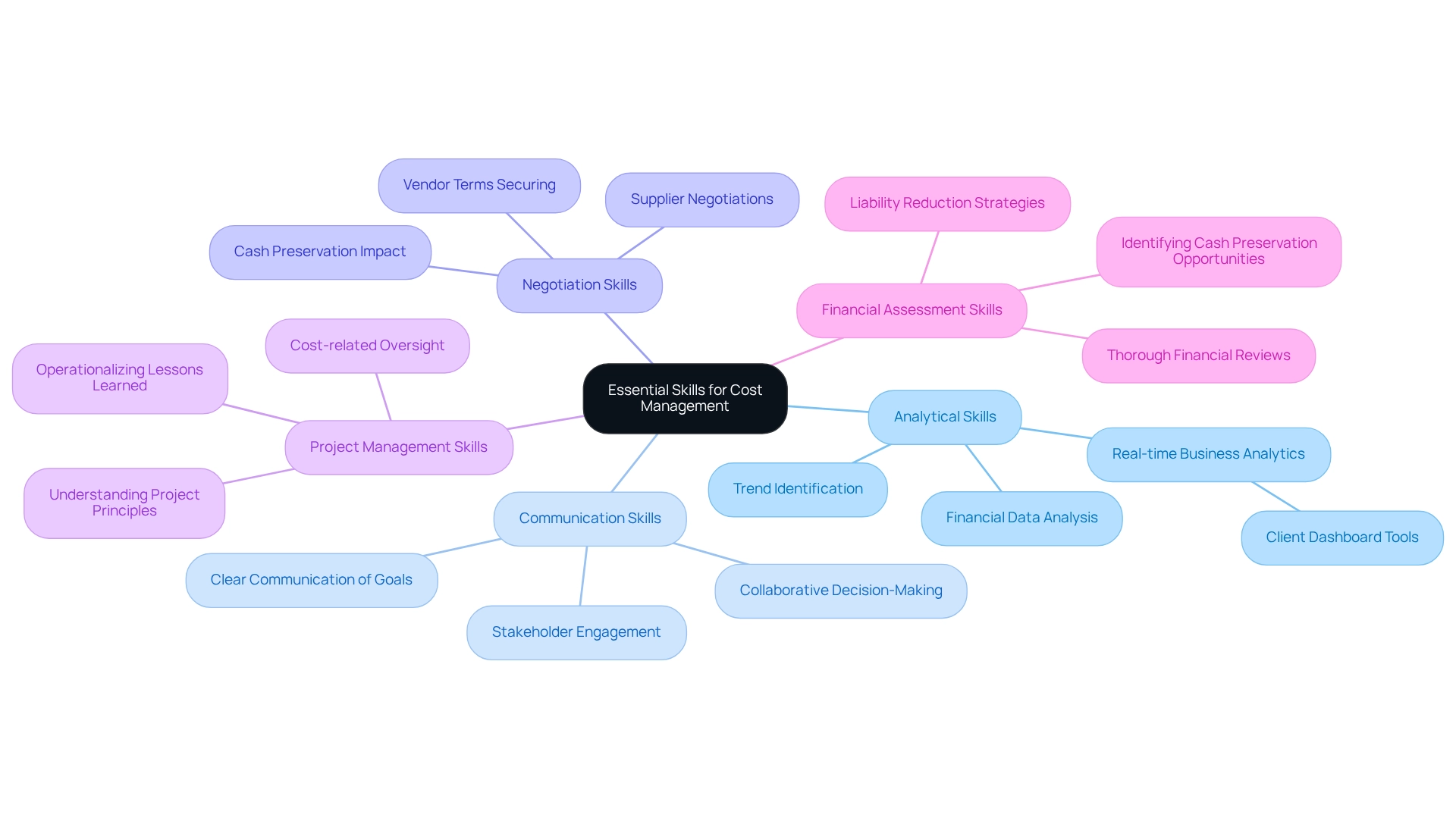

Cultivate Essential Skills for Cost Management

To effectively manage costs, CFOs must cultivate essential skills within their teams to implement engineering cost reduction strategies successfully.

- Analytical Skills: The ability to analyze financial data and identify trends is crucial. This skill is supported by real-time business analytics, which continually diagnoses business health through tools like the client dashboard.

- Communication Skills: Clear communication of financial goals and cost management strategies to all stakeholders is vital. This ensures alignment and buy-in, fostering a collaborative environment for decision-making.

- Negotiation Skills: Proficiency in negotiating with suppliers and vendors allows for securing favorable terms and pricing, significantly impacting cash preservation efforts.

- Project Management Skills: A solid understanding of project management principles is necessary to oversee cost-related aspects of projects effectively. This ensures that turnaround lessons are operationalized for ongoing improvement.

- Financial Assessment Skills: Conducting thorough financial reviews enables the identification of opportunities for cash preservation and liability reduction, which are critical for maintaining business health.

By fostering these skills, CFOs can enhance their team's capability to implement effective engineering cost reduction strategies. This not only drives organizational success but also leverages comprehensive financial reviews to uncover value and reduce costs.

Conclusion

In the evolving landscape of project management, mastering the fundamentals of cost engineering is essential for CFOs seeking to optimize project expenditures. By concentrating on pivotal components such as cost estimation, cost control, and value engineering, organizations can significantly enhance their financial health and ensure projects are completed within budget. A comprehensive understanding of financial assessments further empowers CFOs to uncover value and mitigate risks, which is crucial for navigating financial challenges.

Implementing effective cost engineering techniques—including lean manufacturing, design-to-cost strategies, and automation—can drive substantial cost reductions while fostering a culture of continuous improvement. Moreover, promoting cross-functional collaboration and employing lifecycle cost analysis enables organizations to identify hidden savings and streamline decision-making processes, ultimately resulting in enhanced project quality and performance.

Cultivating essential skills within finance teams, such as analytical, communication, and negotiation skills, is vital for executing successful cost management strategies. By prioritizing these competencies, CFOs can empower their teams to navigate the complexities of cost management effectively, ensuring long-term organizational resilience and growth.

In conclusion, the integration of strategic cost engineering practices not only supports immediate financial goals but also positions organizations for sustainable success in an increasingly competitive landscape. Embracing these principles and fostering a culture of collaboration and continuous improvement will enable CFOs to lead their organizations toward a more efficient and financially sound future.

Frequently Asked Questions

What is cost management in the context of engineering?

Cost management represents the strategic application of engineering principles combined with business acumen to effectively oversee expenses through engineering cost reduction strategies.

What are the key components of cost management?

The key components include cost estimation, which involves accurately forecasting project expenses, and expense management, which entails organizing strategies to oversee and regulate expenses throughout the project lifecycle.

Why is cost estimation important?

Cost estimation is vital for effective budgeting and financial planning, as precise expense assessment directly influences project success and resource allocation.

What does expense management involve?

Expense management involves the organized application of strategies to manage and regulate expenses, preventing budget overruns and ensuring financial stability throughout the initiative.

What is value engineering?

Value engineering focuses on evaluating the functions of a project to enhance value while applying engineering cost reduction strategies, ensuring projects meet quality standards and budgetary constraints.

How can CFOs enhance financial management during economic challenges?

CFOs can enhance financial management by conducting comprehensive monetary evaluations to identify opportunities for conserving cash and reducing liabilities, collaborating with financial specialists to uncover value and mitigate risks.

What is the significance of aligning engineering initiatives with financial objectives?

Aligning engineering initiatives with financial objectives is crucial for implementing engineering cost reduction strategies effectively, ensuring projects are completed on schedule and within budgetary constraints.

How does the current business landscape affect cost management strategies?

In today’s dynamic business landscape, where efficiency is paramount, mastering cost management fundamentals and adapting to evolving engineering trends is increasingly vital for successful financial management.