Introduction

In the highly competitive oil and gas sector, the pursuit of cost efficiency and operational excellence is more critical than ever. As companies navigate fluctuating market conditions and evolving technologies, adopting strategic procurement processes, leveraging advanced technologies, and implementing lean management principles are essential steps toward achieving significant savings and enhanced productivity. This article delves into the most effective strategies for optimizing procurement, enhancing workforce capabilities, and streamlining supply chain management, providing actionable insights that empower organizations to thrive in a dynamic environment.

By embracing these approaches, companies can not only reduce costs but also position themselves for sustained growth and profitability in the face of industry challenges.

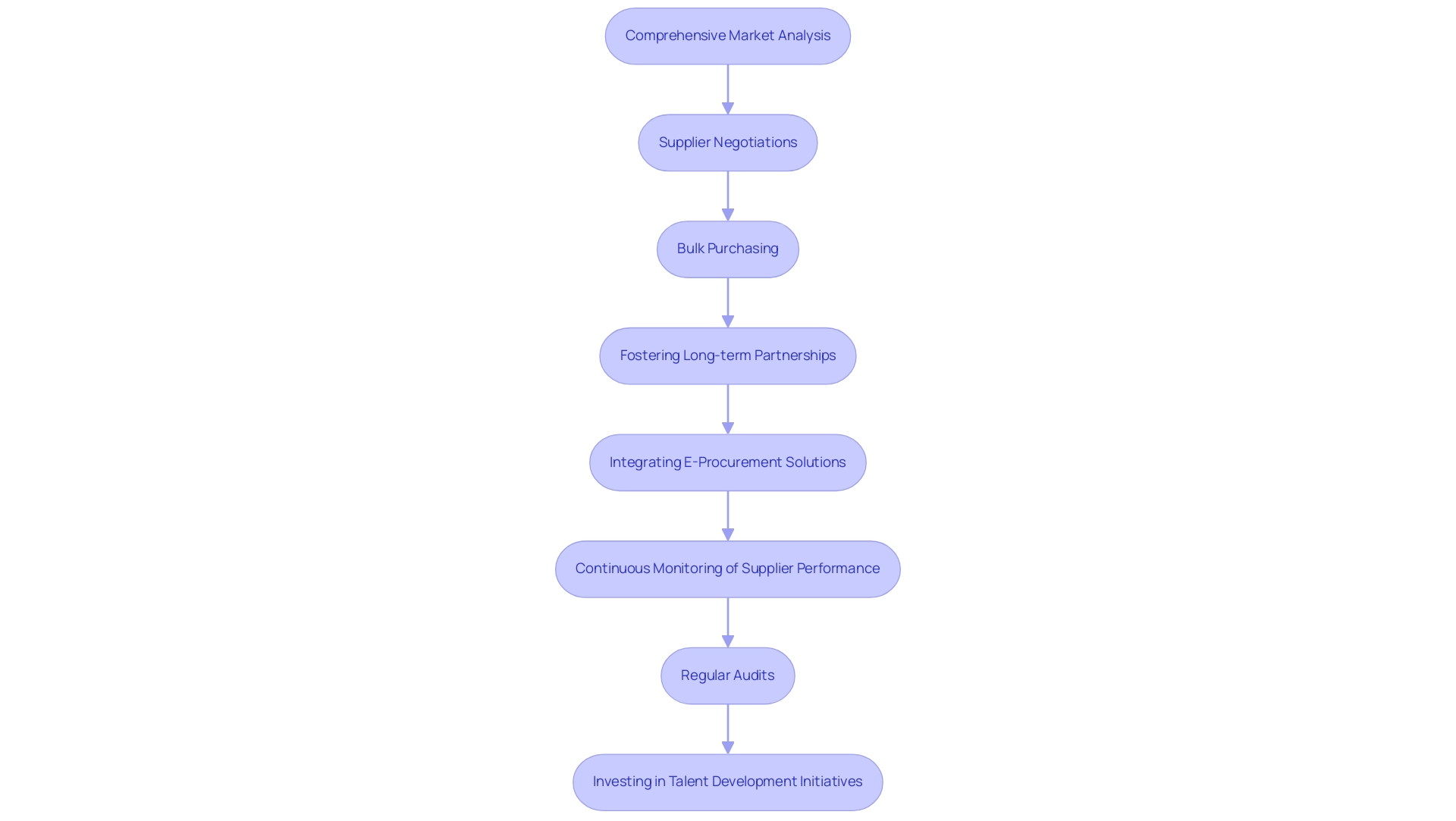

Optimizing Procurement Processes for Cost Efficiency

To enhance efficiency in procurement, organizations within the oil and gas sector must adopt a strategic sourcing framework. This entails a comprehensive market analysis to pinpoint optimal suppliers, followed by negotiations aimed at securing advantageous contract terms. Given the significant influence of oil and gas prices on drilling and completion expense trends, it is crucial for procurement teams to stay informed about these fluctuations as they directly affect input expenses and demand for services.

Utilizing bulk purchasing can further improve savings on a per-unit basis. Additionally, fostering long-term partnerships with key suppliers can unlock improved pricing structures and superior service levels. The integration of e-procurement solutions is crucial as well; these tools not only streamline the purchasing workflow but also minimize administrative expenses and bolster transparency across transactions.

Recent trends indicate that e-procurement solutions are evolving to include advanced analytics and artificial intelligence, which can further optimize procurement processes. Continuous monitoring of supplier performance, coupled with regular audits, ensures that organizations extract maximum value from procurement activities.

Given that only 14% of procurement leaders feel equipped to meet future demands, as highlighted by a Gartner survey, it is imperative for firms to invest in talent development initiatives. As Stefan Gergely notes, 'This disparity between current and future talent availability perceived by procurement leaders underscores the pressing need for organizations to proactively address skill gaps and invest in talent development initiatives.' Tackling these skill gaps will enable procurement teams to execute these strategies efficiently, resulting in significant savings and improved efficiencies.

Leveraging Technology for Enhanced Operational Efficiency

In the oil and gas sector, the adoption of advanced technologies such as automation, artificial intelligence, and data analytics is crucial for enhancing efficiency and decision-making. As Thomas Edison once said, 'There’s a way to do it better—find it.' This mindset drives the industry to embrace innovations like predictive maintenance technologies, which have proven to be game-changers, capable of reducing downtime by proactively identifying potential equipment failures. This progressive strategy not only reduces repair expenses but also maintains production levels.

Furthermore, leveraging real-time data analytics enables companies to gain actionable insights into their performance, continuously monitoring business health and pinpointing inefficiencies for optimized resource allocation. As we transition to cloud-based solutions, we echo the words of Peter Drucker: 'What gets measured gets managed.' Enhanced collaboration and streamlined data sharing among teams facilitate quicker decision-making and improved project outcomes.

By dedicating to these technological investments and keeping a shortened decision-making cycle, organizations can implement lessons learned, enhance their operations, and cultivate strong enduring relationships that lower expenses, positioning themselves for sustained profitability in a competitive landscape. Our client dashboard plays a pivotal role in monitoring success, ensuring that businesses remain agile and responsive to changes in their operational environment.

Implementing Lean Management Principles

Adopting lean management principles can yield substantial savings by emphasizing value creation and the elimination of waste within oil and gas operations. A crucial initial step is the implementation of value stream mapping, which empowers organizations to pinpoint non-value-added activities and streamline their processes effectively.

Kristin Flores, an Industrial Engineer Intern, noted, "I supported the development of a financial analysis tool that identified potential savings of $25,000 annually through process improvements and waste reduction." This statistic underscores the financial benefits of lean practices.

Training employees in lean methodologies is vital to cultivate a culture of continuous improvement, where teams are encouraged to pursue efficiencies in their everyday tasks. Frequent evaluations and modifications of operational practices will guarantee that organizations stay aligned with their expense reduction objectives.

For example, a case study on the expense analysis tool development at EngineerNest Interns demonstrated how applying these strategies can result in substantial savings. By fully adopting lean principles, oil and gas companies can not only attain savings but also improve overall productivity and enhance their responsiveness to market dynamics.

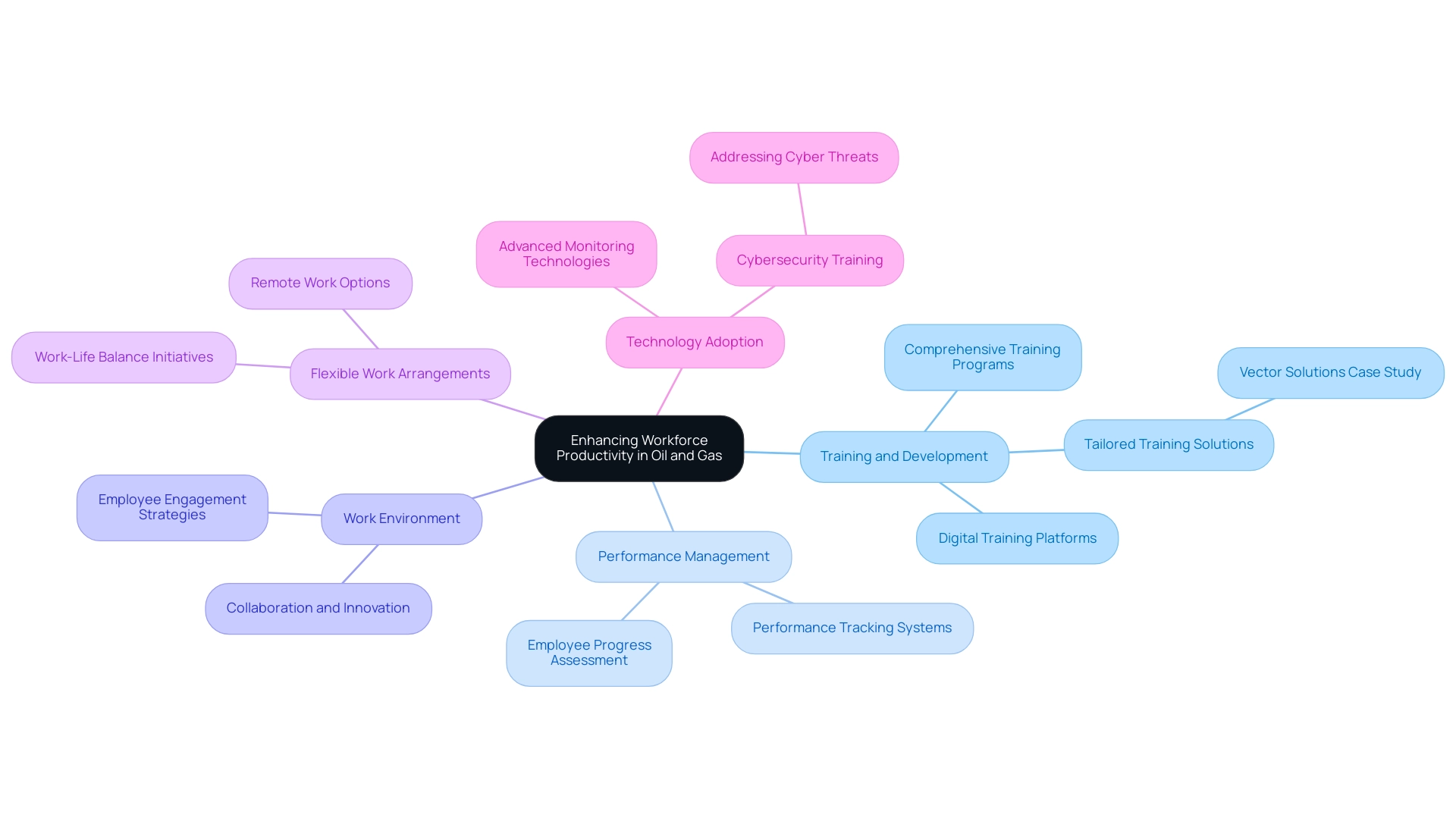

Enhancing Workforce Productivity

To drive workforce productivity in the oil and gas sector, companies must prioritize investment in comprehensive training and development programs. These initiatives are essential for equipping employees with the skills necessary for effective performance in their roles. The implementation of performance management systems serves as a robust framework for tracking employee progress and pinpointing areas that require enhancement. A positive work environment, characterized by collaboration and innovation, significantly boosts employee engagement and retention rates.

Furthermore, adopting flexible work arrangements and leveraging advanced technology for remote monitoring can lead to substantial productivity gains. Notably, 39% of all cyber infrastructure attacks impact the oil and gas sector, highlighting the critical need for skilled employees who can navigate these challenges effectively. By focusing on workforce optimization, organizations set themselves up to attain excellent performance results while concurrently reducing expenses related to employee turnover and inefficiencies.

A case study on Vector Solutions for Oil and Gas Safety demonstrates this: their tailored training solutions aim to improve safety, fill skills gaps, and enhance employee retention. As noted by a Training Analyst,

Vector Solutions gives us the ability to create consistent training experiences for our employees and the ability to deliver those effectively every time—that’s priceless.

This underscores the critical role that tailored training solutions play in the oil and gas industry. Additionally, current trends show a shift towards more digital training platforms and personalized learning experiences, which are becoming increasingly important in meeting the evolving needs of the workforce.

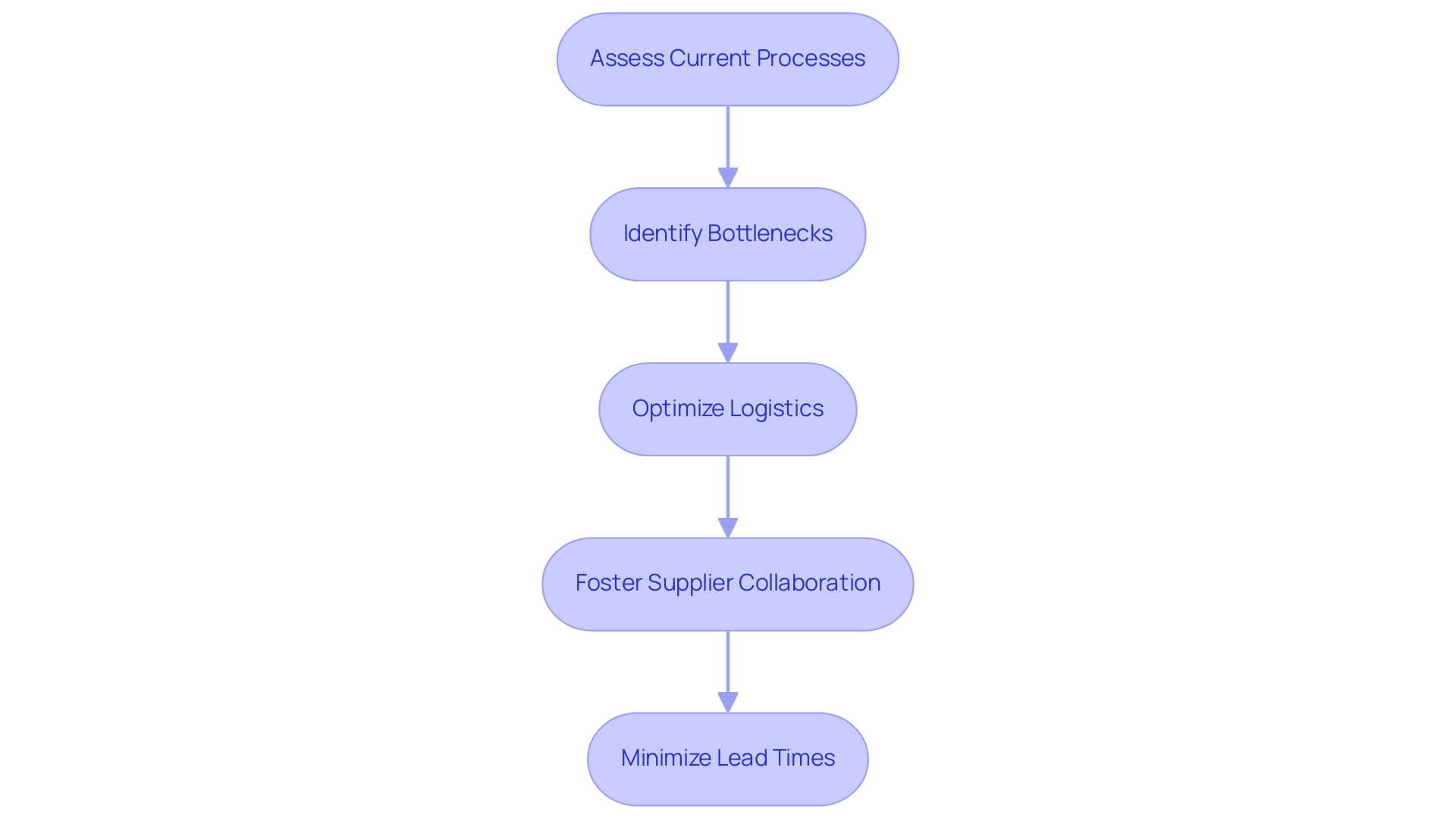

Streamlining Supply Chain Management

Effective supply chain management is essential for oil and gas firms seeking to lower expenses and improve operational efficiency. Key strategies include:

- Optimizing logistics

- Fostering supplier collaboration

- Minimizing lead times

A thorough assessment of current supply chain processes is essential to pinpoint bottlenecks and inefficiencies. The integration of advanced supply chain management software stands out as a transformative solution, offering enhanced visibility and coordination throughout the supply chain. This technology facilitates improved forecasting and inventory management, crucial for maintaining a competitive edge in a rapidly evolving market.

Moreover, creating just-in-time delivery systems in partnership with suppliers can greatly lower inventory holding expenses, thereby enhancing cash flow. As per the most recent statistics, supply chain management efficiency in the oil and gas sector is expected to enhance by 15% in 2024, highlighting the significance of these strategies in achieving savings.

Additionally, a quote from the Global Outlook Report states, "Energy demand is expected to evolve significantly, necessitating a shift in supply chain approaches to meet new market realities.” With projections indicating that energy transition minerals may surpass coal revenues by 2040, companies must pivot swiftly.

By prioritizing supply chain optimization, oil and gas companies can achieve significant reductions in expenses while ensuring the timely delivery of essential materials and services. For instance, a case study on a leading oil company revealed that implementing integrated supply chain management software led to a 20% reduction in operational costs and improved service delivery timelines. This ultimately positions them for success in the shifting energy landscape.

Conclusion

Adopting strategic procurement processes, leveraging advanced technologies, implementing lean management principles, enhancing workforce productivity, and streamlining supply chain management are indispensable strategies for oil and gas companies striving for cost efficiency and operational excellence. Each approach contributes uniquely to reducing costs and boosting productivity, enabling organizations to navigate the complexities of the industry more effectively.

By embracing a strategic sourcing framework, companies can optimize supplier relationships and secure better contract terms, while the integration of e-procurement solutions enhances transparency and reduces administrative burdens. Moreover, the adoption of advanced technologies such as automation and data analytics empowers firms to make informed decisions, reduce downtime, and optimize resource allocation.

Implementing lean management principles fosters a culture of continuous improvement, driving significant savings through waste elimination and process optimization. Furthermore, investing in workforce training and development is crucial for maximizing productivity and ensuring that employees possess the skills necessary to meet current and future challenges.

Finally, effective supply chain management is vital in maintaining competitive advantage, with strategies aimed at optimizing logistics, enhancing supplier collaboration, and reducing lead times. By prioritizing these strategies, oil and gas companies can not only achieve substantial cost reductions but also position themselves for sustained growth and profitability in a rapidly evolving market landscape. Embracing these approaches will empower organizations to thrive amidst industry challenges and secure a robust operational future.

Frequently Asked Questions

What is a strategic sourcing framework in the oil and gas sector?

A strategic sourcing framework involves comprehensive market analysis to identify optimal suppliers, followed by negotiations to secure advantageous contract terms, enhancing procurement efficiency.

Why is it important for procurement teams to monitor oil and gas price fluctuations?

Oil and gas price fluctuations significantly influence drilling and completion expenses, directly affecting input costs and demand for services, making it crucial for procurement teams to stay informed.

How can bulk purchasing benefit organizations in the oil and gas sector?

Bulk purchasing can improve savings on a per-unit basis, leading to cost reductions for organizations.

What role do long-term partnerships with suppliers play in procurement?

Long-term partnerships can unlock improved pricing structures and superior service levels, enhancing overall procurement efficiency.

How do e-procurement solutions contribute to procurement processes?

E-procurement solutions streamline purchasing workflows, minimize administrative expenses, and enhance transparency across transactions.

What recent advancements are being integrated into e-procurement solutions?

Recent trends include the incorporation of advanced analytics and artificial intelligence to further optimize procurement processes.

Why is talent development important for procurement leaders?

Talent development is essential as only 14% of procurement leaders feel equipped to meet future demands, highlighting the need to address skill gaps for efficient strategy execution.

What are lean management principles and how do they apply to the oil and gas sector?

Lean management principles focus on value creation and waste elimination, helping organizations streamline processes and achieve substantial savings.

How can training in lean methodologies benefit employees?

Training in lean methodologies fosters a culture of continuous improvement, encouraging teams to pursue efficiencies in their daily tasks.

What is the significance of performance management systems in workforce productivity?

Performance management systems track employee progress and identify areas for enhancement, contributing to improved performance and engagement.

How can flexible work arrangements impact productivity in the oil and gas sector?

Flexible work arrangements and advanced technology for remote monitoring can lead to substantial productivity gains and improved employee satisfaction.

What strategies can enhance supply chain management in oil and gas firms?

Key strategies include optimizing logistics, fostering supplier collaboration, and minimizing lead times to lower expenses and improve operational efficiency.

How does advanced supply chain management software benefit organizations?

It provides enhanced visibility and coordination, facilitating better forecasting and inventory management, crucial for maintaining a competitive edge.

What are just-in-time delivery systems and how do they affect inventory costs?

Just-in-time delivery systems, created in partnership with suppliers, can significantly lower inventory holding expenses, thereby improving cash flow.

What impact is expected on supply chain management efficiency in the oil and gas sector by 2024?

Supply chain management efficiency is projected to enhance by 15% in 2024, emphasizing the importance of optimization strategies for achieving savings.