Introduction

In a landscape where operational efficiency can define a company's success, logistics cost reduction has emerged as a critical focal point for organizations striving to maintain a competitive edge. As businesses grapple with rising expenses associated with transportation, warehousing, and inventory management, the need for effective strategies to streamline these costs becomes paramount. Embracing a multifaceted approach that includes shipping consolidation, automation, and technology integration can unlock significant savings and enhance service delivery.

Moreover, understanding the role of organizational culture and measuring the impact of these strategies through key performance indicators can further propel businesses toward achieving sustainable growth. This article delves into the essential components of logistics cost reduction, equipping leaders with the insights needed to navigate the complexities of modern supply chains and drive operational excellence.

Understanding Logistics Cost Reduction: Definition and Importance

Logistics cost reduction strategies encompass a range of practices designed to minimize expenditures related to the movement and storage of goods, including transportation, warehousing, inventory management, and order fulfillment. In today's increasingly globalized market, effective supply chain management is not just beneficial; it is essential for sustaining a competitive edge. By lowering operational expenses, organizations can greatly enhance their financial results while concurrently improving service standards, allowing quicker and more effective product delivery to clients.

As operational costs keep increasing, the significance of logistics cost reduction strategies becomes essential for attaining sustainable growth and operational excellence. Notably, recent findings indicate that supply chain managers are encouraged to adopt integrated competing values—specifically developmental, group, and hierarchical cultures—to enhance external integration and tackle sustainability challenges effectively. According to a study involving 11 interviews with top managers, this holistic approach is vital for enhancing operational efficiency and fostering long-term success in a dynamic business environment.

As Carly Fink, a special projects assistant at Rainforest Alliance, emphasizes, 'Organizational culture plays a crucial role in addressing sustainability challenges within logistics management.' Moreover, the case study titled 'Enhancing Sustainable Supply Chain Performance through Organizational Culture' demonstrates how embracing these integrated competing values can result in improved sustainable supply chain performance, highlighting the practical consequences of these approaches.

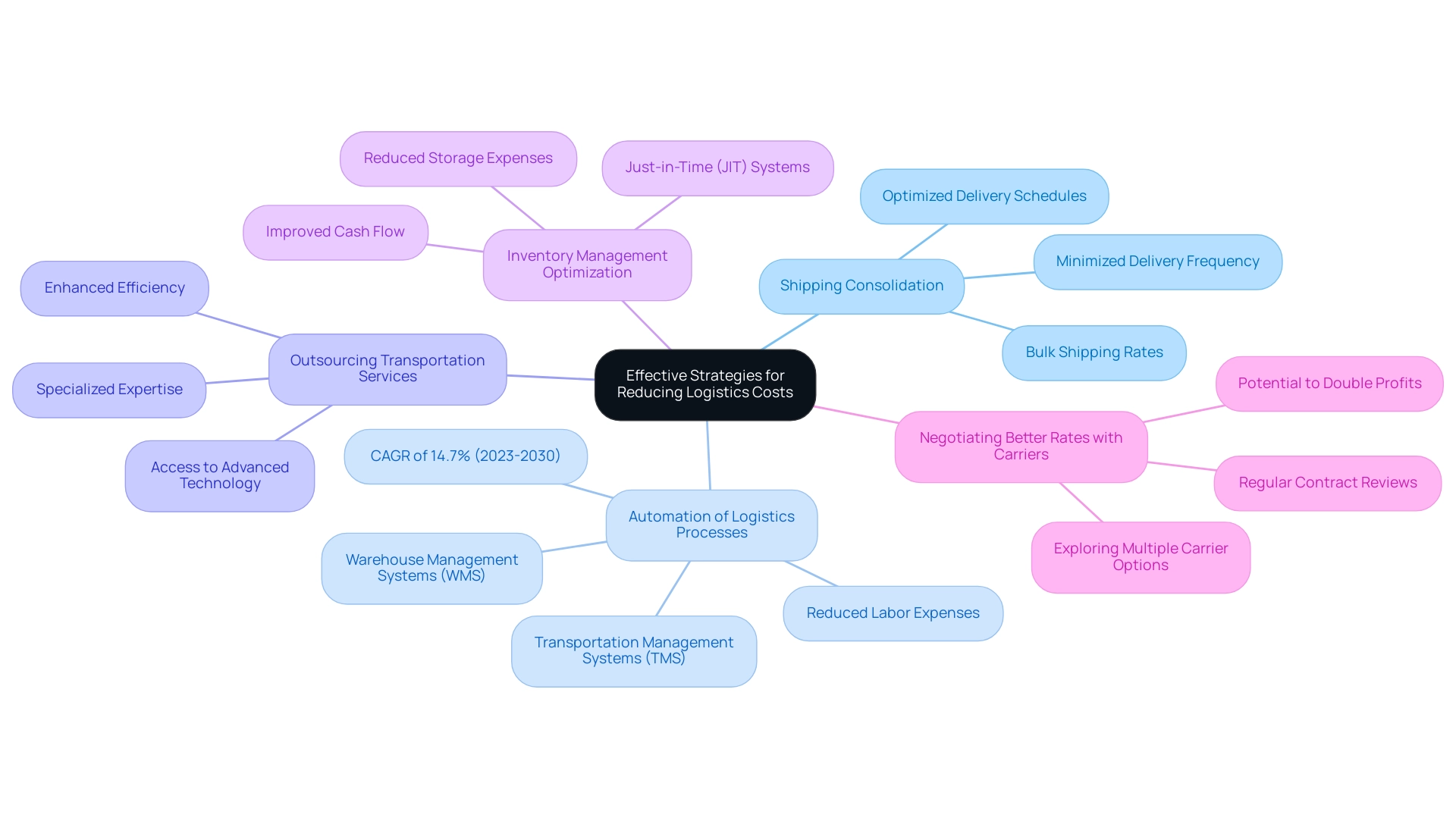

Effective Strategies for Reducing Logistics Costs

- Shipping Consolidation: By merging multiple shipments into one delivery, businesses can realize substantial savings in transportation expenses. This approach not only optimizes delivery schedules and routes but also allows organizations to capitalize on bulk shipping rates, thereby minimizing the frequency of deliveries. Statistics suggest that efficient shipping consolidation can result in substantial savings, emphasizing its significance in a thorough supply chain strategy.

- Automation of Logistics Processes: The implementation of advanced technology solutions, such as warehouse management systems (WMS) and transportation management systems (TMS), can dramatically enhance operational efficiency. These systems simplify processes, minimize manual mistakes, and lead to quicker processing times, ultimately resulting in reduced labor expenses. As the supply chain automation sector is anticipated to expand at a CAGR of 14.7% from 2023 to 2030, companies must acknowledge that incorporating such technologies is essential for remaining competitive and minimizing expenses. This growth highlights the importance of automation in achieving effective expense reduction strategies.

- Outsourcing Transportation Services: Collaborating with third-party providers presents a strategic opportunity for businesses to leverage the specialized expertise and advanced resources of established transportation companies. This method not only decreases the overhead related to managing in-house logistics operations but also provides access to advanced technology and comprehensive logistics networks, thereby enhancing efficiency.

- Inventory Management Optimization: Utilizing efficient inventory management practices, such as just-in-time (JIT) inventory systems, can reduce storage expenses and alleviate surplus inventory. By closely aligning inventory levels with actual demand, companies can avoid the pitfalls of tying up capital in unsold goods, thereby enhancing cash flow and overall financial health.

- Negotiating Better Rates with Carriers: Regularly reviewing contracts with shipping carriers is essential for securing better rates and terms. Businesses should consistently assess their shipping needs and explore multiple carrier options to identify the most cost-effective solutions. As mentioned by Zippia, 'lowering supply chain expenses from 9% to 4% has the potential to double a company’s profits.' This emphasizes the essential requirement for proactive negotiation in attaining substantial savings.

By implementing these thorough logistics cost reduction strategies, organizations can achieve significant decreases in operational expenses while also improving their overall effectiveness and profitability while sustaining high service standards. Considering that the average expense of a supply chain disruption is $1.5 million per day, the urgency of effective financial management strategies cannot be overstated; it is imperative for sustaining competitive advantage in today’s dynamic market.

The Role of Technology in Logistics Cost Reduction

In 2024, technology is poised to be a cornerstone in implementing logistics cost reduction strategies, allowing companies to improve process efficiency and visibility throughout their supply chains. Essential technologies include:

-

Transportation Management Systems (TMS): With a notable user rating of 4.4 based on 90 reviews, Uber Freight exemplifies an effective TMS that simplifies shipping route optimization and carrier relationship management.

While user-friendly, it has been noted that navigation could improve, as one user remarked, > Mostly simple to use, just wish once you are in the think tank you could go back a page; I always have to restart my session. This indicates that while TMS solutions are beneficial, continuous enhancements are necessary to meet user needs effectively.

-

Warehouse Management Systems (WMS): WMS solutions are integral for managing inventory levels, offering real-time shipment tracking, and automating warehouse operations.

These capabilities not only support logistics cost reduction strategies by reducing labor expenses but also improve accuracy in order fulfillment, ultimately contributing to a leaner supply chain.

-

Data Analytics: Utilizing data analytics tools enables organizations to reveal trends, accurately predict demand, and make strategic choices concerning inventory and supply chain. This proactive strategy is part of logistics cost reduction strategies that can significantly reduce expenses linked to overstocking or stockouts.

-

Internet of Things (IoT): IoT technology facilitates real-time tracking of shipments and monitoring of environmental conditions. This ability allows supply chain managers to proactively tackle possible challenges, minimizing the chances of losses from spoilage or damage.

By embracing these technologies, organizations can greatly improve efficiency in their operations, which supports logistics cost reduction strategies and sets the stage for considerable savings. Furthermore, industry leaders have recognized the scalability and effectiveness of solutions like BluJay Transportation Management, which has also received a commendable rating of 4.4 from 22 reviews. BluJay's capabilities, including advanced analytics and smooth integration with current systems, enhance operational efficiency and expense management.

Case studies, including TESI's dedication to professionalism and customized solutions, demonstrate how their targeted logistics cost reduction strategies have led to a 15% decrease in operational expenses and improved service delivery times, highlighting the concrete advantages of technology in managing expenses.

Measuring the Impact of Logistics Cost Reduction Strategies

To effectively assess the influence of logistics cost reduction strategies, organizations must track key performance indicators (KPIs) that accurately reflect their operational efficiency and savings. Notable KPIs to consider include:

-

Transportation Expenses as a Percentage of Sales: This essential metric assesses the relationship between logistics expenditures and overall revenue, providing valuable insights into efficiency.

As a benchmark, transportation expenses are projected to significantly influence sales metrics in 2024. With global investment declarations surpassing USD 275 billion in electric vehicles (EVs) and USD 195 billion in batteries, comprehending these expenses is vital as the automotive market develops.

-

Order Fulfillment Cycle Time: By measuring the duration from order placement to delivery, businesses can identify enhancements in distribution processes and their corresponding effects on customer satisfaction and retention.

-

Inventory Turnover Ratio: This ratio indicates the efficiency of inventory management, with higher turnover rates signifying effective practices. As the automotive industry shifts towards electrification, understanding inventory dynamics will be vital for suppliers adapting to changing market demands. Elizabeth Connelly, lead author, notes that this shift is reflected in the sales share for cars in the STEPS (almost 45%) and the share implied by government ambitions in the APS (almost 50%).

-

Expense per Order: This KPI, which divides the total transportation expense by the number of orders, provides a clear view of the expense structure, allowing companies to pinpoint areas ripe for improvement.

Regularly monitoring these KPIs enables organizations to critically assess the effectiveness of their logistics cost reduction strategies, facilitating data-driven adjustments that enhance overall performance. The recent surge in global electric car sales, which exceeded 14 million in 2023 and represented around 18% of all cars sold, highlights the significance of these metrics as more than 20 original equipment manufacturers (OEMs) aim for substantial electric vehicle deployments, ensuring that operations align with broader market trends.

Challenges in Implementing Logistics Cost Reduction Strategies

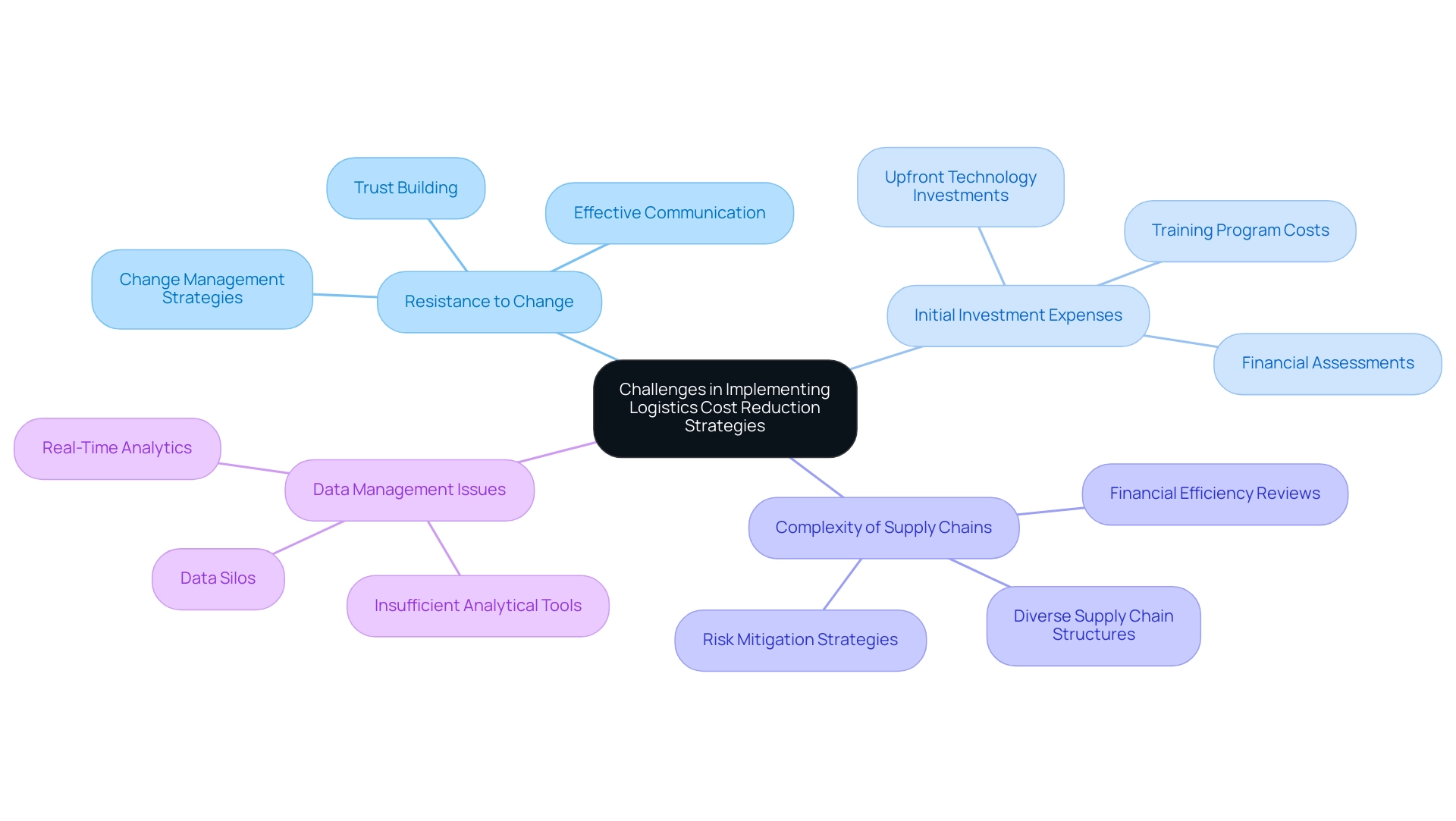

Implementing logistics cost reduction strategies presents several significant challenges that organizations must navigate carefully:

- Resistance to Change: Resistance from employees and stakeholders can impede the adoption of new processes or technologies. Building trust and communication during transitions is crucial; as Ion Popescu noted, "I became someone the other guys in prison could trust. I would listen to them and share my own story." Effective change management strategies are essential to ensure buy-in and foster a culture of adaptability within the organization.

- Initial Investment Expenses: Numerous expense-saving techniques necessitate significant upfront investments, especially in advanced technology and thorough training programs. While these investments may appear daunting, they are crucial for achieving long-term savings and operational efficiency. A thorough financial assessment, which includes a detailed examination of your company’s financial operations, can identify opportunities to preserve cash and reduce liabilities, emphasizing the significance of strategic investments in supply chain management. In the context of recent economic trends, it is noteworthy that it would take another 274,000 state and local government jobs to restore employment to pre-pandemic levels on a per capita basis, highlighting the need for careful planning.

- Complexity of Supply Chains: Today's supply chains are frequently complicated and diverse, making it difficult to identify the most effective methods for reducing expenses tailored to specific business contexts. This complexity demands a comprehensive financial review focusing on cash preservation, financial efficiency, and risk mitigation to uncover hidden value and reduce costs, ensuring operations are optimized effectively. Understanding the complexities involved in financial reviews is essential for identifying the right strategies.

- Data Management Issues: Accurate data is the backbone of effective supply chain management. However, organizations frequently encounter difficulties such as data silos or insufficient analytical tools, which hinder their ability to leverage operational data for informed decision-making. Streamlined decision-making and real-time analytics, as supported by effective financial reviews, allow businesses to continually monitor their performance and modify approaches as needed. Moreover, the recent alterations in right-to-work laws in states with traditionally elevated unionization levels highlight the intricacies of labor dynamics that may influence strategies for minimizing expenses.

By proactively recognizing and addressing these challenges, along with implementing thorough financial assessments that include detailed examinations of financial operations and continuous performance monitoring, businesses can lay the groundwork for successful logistics cost reduction strategies, ultimately driving efficiency and profitability.

Conclusion

Logistics cost reduction is a vital strategy for organizations aiming to thrive in today’s competitive landscape. By understanding the definition and importance of logistics cost reduction, businesses can appreciate the direct correlation between minimizing expenses and enhancing service delivery. Emphasizing strategies such as shipping consolidation, automation, and outsourcing not only leads to significant cost savings but also boosts overall operational efficiency.

The role of technology cannot be overstated in this context. Implementing advanced systems like Transportation Management Systems (TMS) and Warehouse Management Systems (WMS) empowers organizations to streamline their logistics processes, resulting in improved accuracy and reduced labor costs. Moreover, measuring the impact of these strategies through key performance indicators (KPIs) ensures that businesses remain agile and responsive to market demands.

However, the journey toward effective logistics cost reduction is not without challenges. Resistance to change, initial investment costs, and the complexity of supply chains can hinder progress. By addressing these obstacles head-on and fostering a culture of adaptability, organizations can successfully implement cost reduction strategies that not only enhance profitability but also position them for sustainable growth in a rapidly evolving market.

In conclusion, embracing a multifaceted approach to logistics cost reduction is essential for maintaining competitive advantage. By leveraging technology, optimizing processes, and effectively measuring outcomes, organizations can unlock the full potential of their supply chains, ensuring they remain resilient and prepared for future challenges.

Frequently Asked Questions

What are logistics cost reduction strategies?

Logistics cost reduction strategies are practices aimed at minimizing expenses related to the movement and storage of goods, including transportation, warehousing, inventory management, and order fulfillment.

Why are logistics cost reduction strategies important in today's market?

They are essential for sustaining a competitive edge by lowering operational expenses, enhancing financial results, and improving service standards, which allows for quicker and more effective product delivery.

What role does organizational culture play in logistics management?

Organizational culture is crucial in addressing sustainability challenges within logistics management, as it influences how effectively companies implement logistics cost reduction strategies.

What are some key logistics cost reduction strategies mentioned in the article?

Key strategies include: 1. Shipping Consolidation 2. Automation of Logistics Processes 3. Outsourcing Transportation Services 4. Inventory Management Optimization 5. Negotiating Better Rates with Carriers.

How does shipping consolidation help reduce costs?

Shipping consolidation merges multiple shipments into one delivery, resulting in savings on transportation expenses, optimized delivery schedules, and bulk shipping rates.

What benefits does automation of logistics processes provide?

Automation enhances operational efficiency by simplifying processes, reducing manual errors, and leading to quicker processing times, which ultimately lowers labor expenses.

How can outsourcing transportation services be beneficial?

Outsourcing allows businesses to leverage the expertise and resources of third-party providers, reducing overhead costs associated with in-house logistics operations and improving efficiency.

What is inventory management optimization, and how does it help?

It involves practices like just-in-time (JIT) inventory systems to align inventory levels with actual demand, reducing storage costs and improving cash flow by avoiding excess inventory.

Why is it important to negotiate better rates with carriers?

Regularly reviewing and negotiating contracts with shipping carriers can secure better rates and terms, which is crucial for reducing supply chain expenses and improving profitability.

What technologies are essential for implementing logistics cost reduction strategies?

Essential technologies include Transportation Management Systems (TMS), Warehouse Management Systems (WMS), Data Analytics, and the Internet of Things (IoT).

What challenges do organizations face when implementing logistics cost reduction strategies?

Challenges include resistance to change, initial investment expenses, complexity of supply chains, and data management issues.

How can organizations track the effectiveness of their logistics cost reduction strategies?

Organizations can track key performance indicators (KPIs) such as transportation expenses as a percentage of sales, order fulfillment cycle time, inventory turnover ratio, and expense per order.