Introduction

Navigating the complexities of refinery turnarounds requires a strategic approach that balances operational efficiency with safety and compliance. These critical projects, which necessitate halting refinery operations for maintenance and upgrades, are fraught with challenges that demand meticulous planning and execution.

With financial stakes underscored by fluctuating oil prices and the need for enhanced productivity, organizations must adopt best practices that prioritize:

- Effective communication

- Real-time analytics

- Robust risk management

As the industry evolves, leveraging technology becomes essential for streamlining processes and ensuring that turnarounds not only meet but exceed performance expectations.

This article delves into the essentials of turnaround management, exploring the lifecycle of planning, execution, and evaluation, while highlighting innovative strategies and safety considerations that can transform challenges into opportunities for growth.

Understanding the Essentials of Refinery Turnarounds

Refinery turnaround management services are crucial during maintenance periods, which represent significant challenges that demand meticulous planning and precise execution, with a strong emphasis on streamlined decision-making and real-time analytics. These complex projects necessitate a temporary halt in refinery operations to facilitate essential maintenance, upgrades, and repairs, which are critical components of refinery turnaround management services aimed at enhancing operational efficiency and safety. In June 2018, the monthly average refiner acquisition cost was $68.35 per barrel, highlighting the financial stakes involved in management of changes.

Successful strategies hinge on a thorough understanding of the refinery's operational needs, financial ramifications, and the regulatory landscape, while employing refinery turnaround management services to continuously test hypotheses and deliver maximum return on invested capital. As EOG Resources mentioned, their total production reached 1.1 MMboe/d, with crude oil making up 50% of the total, emphasizing the significance of operational efficiency during transitions. Effective communication with all stakeholders—including employees and suppliers—is crucial to align expectations and facilitate a seamless process, while a commitment to operationalizing lessons learned fosters strong, lasting relationships.

This operationalization is backed by ongoing monitoring via a client dashboard, which offers real-time business analytics to evaluate the effectiveness of recovery strategies. Moreover, organizations must critically evaluate their internal capabilities and resources to decide whether to deploy in-house teams or engage external consultants for refinery turnaround management services, ensuring that the process is executed efficiently and effectively. The situation of Valero, which reported a decline in net income to $364 million in the third quarter of 2024, emphasizes the real-world implications of management recovery.

Despite challenges, Valero's renewable diesel segment demonstrated resilience, reporting an operating income of $35 million, illustrating the potential for strategic focus during recoveries. In 2024, the average duration of refinery maintenance varies by region, highlighting the need for tailored strategies that account for specific operational contexts and challenges.

The Turnaround Lifecycle: Planning, Execution, and Evaluation

The lifecycle of the process is critical in managing refinery operations and is an essential aspect of refinery turnaround management services, which can be divided into three fundamental phases:

- Planning

- Execution

- Evaluation

In the planning phase, defining clear objectives is paramount, alongside effective resource allocation, such as the supply capacity for makeup water, which is 50 m³/h (equivalent to 1200 m³/d). This stage involves comprehensive risk assessments and testing hypotheses to identify potential challenges that could affect the success of refinery turnaround management services, ensuring maximum return on invested capital. As the plan transitions into the execution phase, the focus shifts to effectively implementing the refinery turnaround management services strategy.

This entails coordinating various groups, utilizing the client dashboard for real-time analytics to monitor progress diligently, and upholding stringent safety protocols to mitigate risks within the complex environment of refinery operations. Successful execution of refinery turnaround management services hinges on clear communication and defined roles among team members, which can vastly improve efficiency. The ability to make quick decisions during this phase is vital to preserve business operations and maintain momentum, with the shortened decision-making cycle allowing for rapid adjustments as needed.

The final phase, evaluation, is crucial for assessing the success of the refinery turnaround management services. Organizations should measure outcomes against the original objectives, leveraging real-time business analytics from the client dashboard to conduct thorough reviews capturing valuable lessons learned. This process is essential in refining future recovery strategies and fostering a culture of continuous improvement with the help of refinery turnaround management services.

Challenges often arise during this phase, as highlighted in the case study titled 'Review Phase of Turnaround,' where incomplete data and undefined key performance indicators (KPIs) can impede accurate assessments. Therefore, establishing robust metrics beforehand is vital to facilitate effective evaluations that can inform subsequent refinery turnaround management services. As mentioned by Emily Newton in '3 Ways AI Transforms Manufacturing for a Greener Tomorrow,' incorporating advanced technologies can further improve planning and execution phases, fostering innovative solutions in process oversight while applying lessons to establish strong, enduring relationships.

Best Practices for Successful Turnaround Management

Effective management of change is built on several essential best practices that ensure successful outcomes. First and foremost, establishing a clear leadership structure is crucial; this structure should delineate roles and responsibilities, facilitating streamlined decision-making that can adapt to the fast-paced nature of rapid change situations. Contributing to this success is the SMB group's experience, as highlighted by a client who stated,

'Within 100 days of meeting the SMB group, my business was in a better position financially and strategically than it had been in years.'

This reflects the impactful results of their innovative 'Rapid30' plan, which not only identifies key business issues but also provides actionable strategies for improvement. Effective communication among all stakeholders is equally important; fostering transparency encourages collaboration and aligns objectives across the organization. Moreover, leveraging data-driven insights empowers leaders to make informed decisions throughout the recovery process.

Regular progress evaluations against set milestones are essential, allowing groups to pivot and modify strategies when needed to tackle emerging challenges. The statistic that only 20 to 25 work orders are requested during the scope challenge process, with only 4 to 5 approved, emphasizes the difficulties encountered during recoveries, such as resource limitations and prioritization problems, and highlights the significance of effective oversight practices. Furthermore, engaging business advisory experts, like the SMB team, guarantees a thorough approach to financial evaluation, temporary oversight, operational efficiency, and effective refinery turnaround management services.

Their services encompass:

- Refinery turnaround management services

- Restructuring consulting

- Interim management services

- Financial assessment

- Bankruptcy case management

All tailored for small and medium enterprises. Documenting lessons learned from each recovery enhances future initiatives and builds a repository of organizational knowledge that can inform subsequent efforts. As mentioned by Rosabeth Moss Kanter,

'Each had to lead a psychological change,' emphasizing the necessity for leaders to engage and motivate their teams during these critical transformations.

Furthermore, case studies indicate that selecting vendors offering localized support can significantly impact efficiency, as reliable partners provide on-site assistance and ensure timely access to critical system parts. By adopting these best practices, CFOs can significantly enhance the expectations and results related to recovery initiatives in 2024 and beyond.

Leveraging Technology for Enhanced Turnaround Efficiency

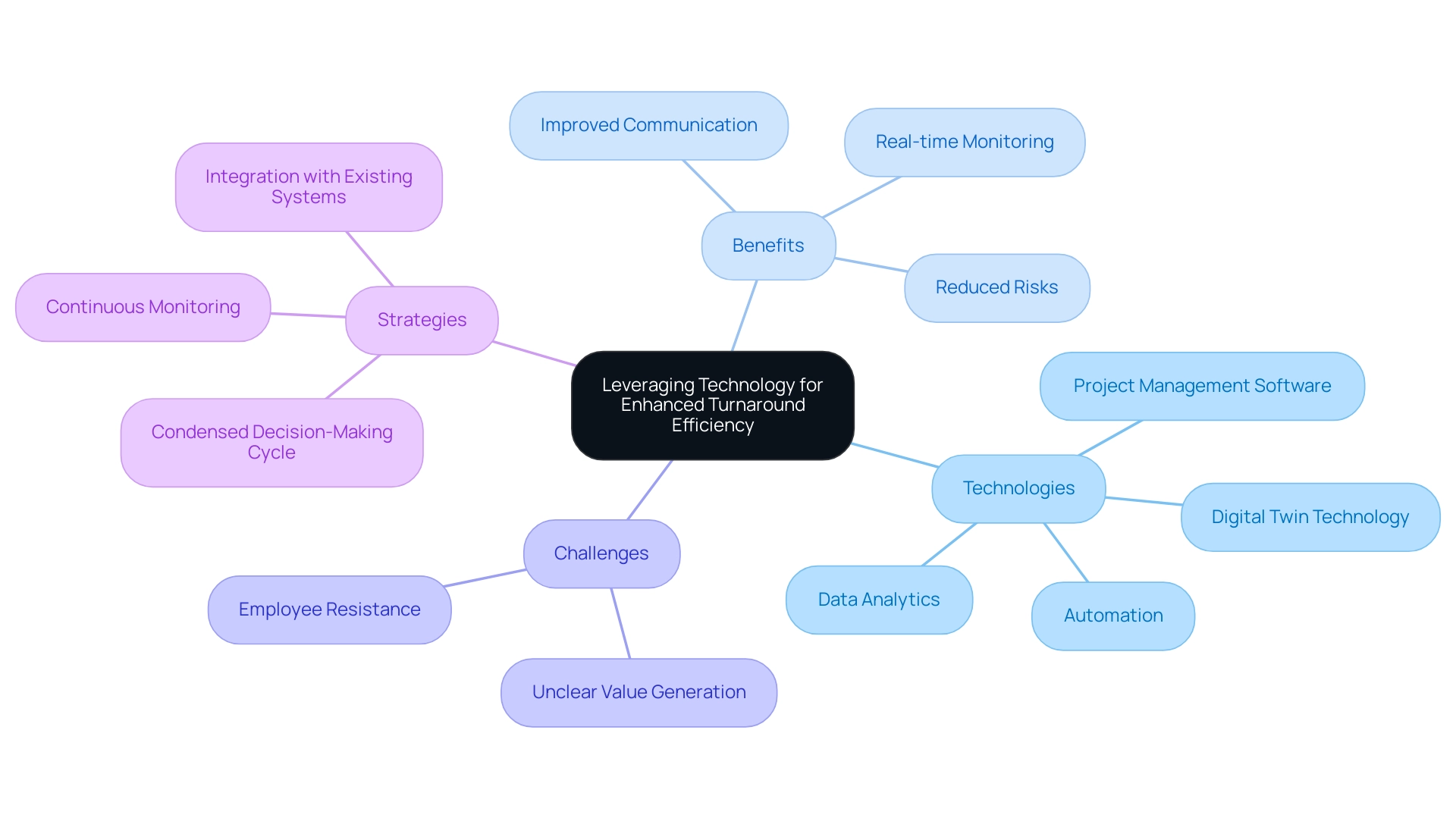

Integrating technology into recovery processes is not only advantageous; it is crucial for attaining substantial efficiency improvements. By leveraging advanced project management software, organizations can streamline communication and enable real-time progress tracking, ensuring that all stakeholders are aligned and informed. Our group advocates for a condensed decision-making cycle during the recovery process, enabling your group to take decisive action to safeguard your business.

Additionally, our pragmatic approach to data emphasizes the importance of testing every hypothesis to maximize return on invested capital in both the short and long term. The application of advanced data analytics tools allows organizations to continuously monitor operational performance through our client dashboard, identifying specific areas ripe for improvement. The innovative use of digital twin technology within refinery turnaround management services facilitates the virtual modeling of refinery operations, enabling teams to simulate and test changes prior to implementation, thus minimizing risks.

Automation plays a crucial role as well, enhancing safety and reducing the need for manual labor during transitions. However, many oil and gas companies face challenges in scaling these digital initiatives, as highlighted in the case study 'Barriers to Digital Transformation.' Key barriers include:

- Unclear value generation from technologies

- Employee resistance to new processes

It's vital for organizations to stay informed about the latest technological advancements, as a recent study by the Carbon Trust indicates that 85.5% of emissions can be avoided by transitioning from traditional data centers to cloud infrastructure, which optimizes operational efficiency. Furthermore, our ongoing commitment to implementing the lessons learned through the recovery process ensures that relationships built during this time are strong and lasting. Economic factors, such as gas prices, can significantly affect crude oil prices, influencing management strategies.

By adopting these technologies, organizations can not only enhance results but also sustain a competitive advantage in a continually changing industry environment. As noted by industry experts, 'The integration of technology is not merely an option; it's a necessity for driving efficiency and sustainability in refinery turnaround management services operations.

Safety and Environmental Considerations in Turnaround Management

Safety and environmental considerations are crucial during refinery shutdowns, particularly noting that nearly half of work-related accidents in manufacturing happen during maintenance outages. A proactive method entails performing comprehensive inspections before the changeover starts to identify possible risks and devise effective mitigation plans. Engaging employees in safety training sessions is essential; it enhances their understanding of protocols and emergency procedures, ultimately fostering a safer work environment.

A. G. Cardoso emphasizes the importance of incorporating a human risk factor control program, stating,

When integrated into a human risk factor control program, it could enable identifying measures specifically focused on workers, enhancing their risk perception, thus promoting safe behavior and assisting in reducing the high accident frequency caused by human error during maintenance periods.

Furthermore, adherence to environmental regulations is crucial to avoid penalties and safeguard the community. This encompasses proper waste management practices and stringent emissions controls.

Recent information suggests that planning refinery closures poses difficulties like unexpected technical problems and resource limitations, which highlights the necessity for refinery turnaround management services to ensure strict adherence to health and environmental regulations. To demonstrate the significance of protective measures, a case study on Personal Protective Equipment (PPE) shows that ensuring all workers have suitable PPE greatly decreases the chances of injuries and improves overall security during transitions. To enhance compliance and instill a culture of security throughout the turnaround process, organizations should consider establishing a dedicated environmental and risk task force.

This task force can oversee compliance efforts, ensuring that health and environmental standards are consistently met. Additionally, the introduction of a new conceptual framework for occupational health and safety management systems could simplify implementation for smaller businesses, further supporting their safety initiatives.

Conclusion

Successful refinery turnarounds hinge on meticulous planning, effective execution, and thorough evaluation. By understanding the intricacies of the turnaround lifecycle, organizations can set clear objectives and allocate resources efficiently, ensuring that operational and financial goals are met. The emphasis on real-time analytics and effective communication throughout each phase fosters a culture of collaboration and responsiveness, enabling teams to adapt swiftly to challenges as they arise.

Implementing best practices is vital for achieving desired outcomes. Establishing a clear leadership structure enhances decision-making, while regular progress reviews allow for timely adjustments to strategies. Leveraging technology not only streamlines processes but also drives innovation, enabling teams to simulate scenarios and minimize risks before actual implementation. This proactive approach to turnaround management is essential in maintaining operational efficiency and safety, particularly in an industry where the stakes are high.

Moreover, prioritizing safety and environmental considerations is non-negotiable. By conducting thorough audits and engaging employees in safety training, organizations can mitigate risks associated with maintenance outages. A commitment to adhering to regulatory standards safeguards both the workforce and the surrounding community, reinforcing the importance of operational integrity.

As the refinery landscape continues to evolve, embracing these strategies and technologies positions organizations to navigate the complexities of turnarounds effectively. By transforming challenges into opportunities, businesses can not only enhance their operational performance but also secure a competitive edge in an ever-changing industry. Now is the time to implement these insights, ensuring that future turnarounds drive growth and sustainability.

Frequently Asked Questions

What are refinery turnaround management services?

Refinery turnaround management services are essential during maintenance periods that require a temporary halt in refinery operations for maintenance, upgrades, and repairs. These services focus on enhancing operational efficiency and safety through meticulous planning and execution.

Why is planning important in refinery turnaround management?

Planning is crucial as it involves defining clear objectives, effective resource allocation, and conducting comprehensive risk assessments. This stage aims to identify potential challenges and maximize the return on invested capital.

What are the three fundamental phases of refinery turnaround management?

The three fundamental phases are Planning, Execution, and Evaluation.

What happens during the execution phase of refinery turnaround management?

During the execution phase, the focus shifts to implementing the strategy, coordinating teams, using real-time analytics for monitoring, and upholding safety protocols to mitigate risks.

How does effective communication impact refinery turnaround management?

Effective communication is vital for aligning expectations among all stakeholders, including employees and suppliers, which facilitates a seamless process and improves efficiency.

What role does real-time analytics play in refinery turnaround management?

Real-time analytics, accessed via a client dashboard, allows organizations to monitor progress, evaluate recovery strategies, and make informed decisions quickly during the turnaround process.

What is the significance of the evaluation phase in refinery turnaround management?

The evaluation phase assesses the success of the turnaround efforts by measuring outcomes against original objectives and capturing lessons learned to refine future strategies.

What challenges can arise during the evaluation phase?

Challenges include incomplete data and undefined key performance indicators (KPIs), which can hinder accurate assessments. Establishing robust metrics beforehand is essential for effective evaluations.

How can advanced technologies improve refinery turnaround management?

Incorporating advanced technologies can enhance the planning and execution phases, fostering innovative solutions and improving process oversight while applying lessons learned to build strong relationships.

Why is stakeholder engagement important during refinery turnarounds?

Engaging stakeholders is crucial to align expectations, facilitate communication, and ensure that everyone involved understands their roles, which contributes to a smoother turnaround process.