Introduction

Navigating the complexities of plant shutdowns and turnarounds is a critical endeavor for organizations aiming to optimize operational efficiency and bolster financial performance. As industries evolve, the necessity for robust planning and execution becomes increasingly apparent, with recent statistics indicating a shift towards data-driven decision-making and real-time analytics.

This article delves into the essential phases of shutdown and turnaround management, emphasizing the importance of:

- Thorough assessments

- Strategic planning

- Best practices during execution

By leveraging insights from industry experts and case studies, stakeholders can enhance their understanding of these processes, ultimately leading to improved outcomes and sustainable growth. With the right approach, organizations can not only mitigate risks but also capitalize on opportunities for advancement in an ever-changing landscape.

Understanding Plant Shutdowns and Turnarounds

Plant shutdown and turnaround management are essential processes that can arise from maintenance needs, upgrades, or financial restructuring efforts. Conversely, a turnaround represents a strategic initiative aimed at revitalizing an underperforming operation. Understanding these concepts is crucial for stakeholders, as their comprehension directly influences operational efficiency and financial stability in the context of plant shutdown and turnaround management.

Recent statistics indicate that the landscape of vegetation management is evolving, especially with the growing emphasis on streamlined decision-making and real-time analytics. For instance, as of 2024, the largest nuclear reactors under construction worldwide boast a combined gross capacity of over 20,000 megawatts, underscoring the industry's focus on enhancing energy production capabilities. As highlighted by Krishnankutty et al., utilizing a decision matrix during plant shutdown and turnaround management can significantly enhance performance for contractors and plant owners.

This approach supports a shortened decision-making cycle, allowing teams to act decisively and preserve business health. Furthermore, Dhandha highlights inspection requirements in oil and gas refineries, emphasizing the necessity for thorough evaluations to ensure compliance and safety during closures. A thorough assessment of both functional and financial aspects is essential—organizations must consistently track performance through real-time analytics, supported by client dashboards, to attain successful results in their plant shutdown and turnaround management initiatives.

Moreover, the case study on the automation of on-stream inspections and PACM illustrates how integrating autonomous systems and machine learning can significantly improve maintenance efficiency and reduce costs, operationalizing the lessons learned for sustainable growth. Testing hypotheses throughout this process ensures that strategies are effectively validated and adjusted based on real-time data.

Key Phases of Shutdown and Turnaround Management

Efficient administration of plant shutdown and turnaround management is vital for maximizing productivity and seizing project prospects. Failing to properly execute plant shutdown and turnaround management can lead to missed capital project opportunities, underscoring the urgency of structured planning. This process generally unfolds in several key phases:

-

Assessment: Begin by thoroughly evaluating the current functional and financial status of the plant. This foundational step is essential for identifying strengths and weaknesses that will inform your subsequent strategies. Leverage real-time analytics to gain insights into business health, allowing for data-driven decision-making.

Additionally, implement a 'Test & Measure' approach by testing hypotheses related to operational improvements, ensuring that decisions are based on empirical evidence to maximize returns on invested capital.

-

Planning: Develop a comprehensive plan that encompasses timelines, resource allocation, and risk management strategies. This phase is critical, as failing to strategize properly can lead to missed capital project opportunities.

Implementing an Advanced Shutdown Turnaround and Start-Up training course can significantly enhance planning and scheduling methodologies as part of effective plant shutdown and turnaround management, guided by experts with over 30 years of industry experience. Effective planning is rooted in a pragmatic approach to data, ensuring that all decisions are informed by accurate and relevant information.

-

Execution: Carry out the cessation and turnaround activities in strict accordance with the established plan.

It is vital to maintain clear communication among all stakeholders to ensure alignment and address any challenges that may arise. A shortened decision-making cycle will facilitate quick resolutions and preserve business integrity.

-

Review: Conduct an exhaustive evaluation of the entire process post-execution to identify both successes and areas in need of improvement.

Utilize the client dashboard for continuous business performance monitoring, ensuring that findings from the review drive ongoing improvement efforts in planning and execution. A practical example of effective planning is the implementation of a cutoff date to manage the integration of new work into the closing schedule. This strategy prevents scope creep and maintains the integrity of the schedule, ensuring that all work is planned in advance.

By adhering to these phases and operationalizing the lessons learned, organizations can enhance their plant shutdown and turnaround management strategies, achieve higher success rates, and build lasting relationships with stakeholders.

The Importance of Planning and Preparation

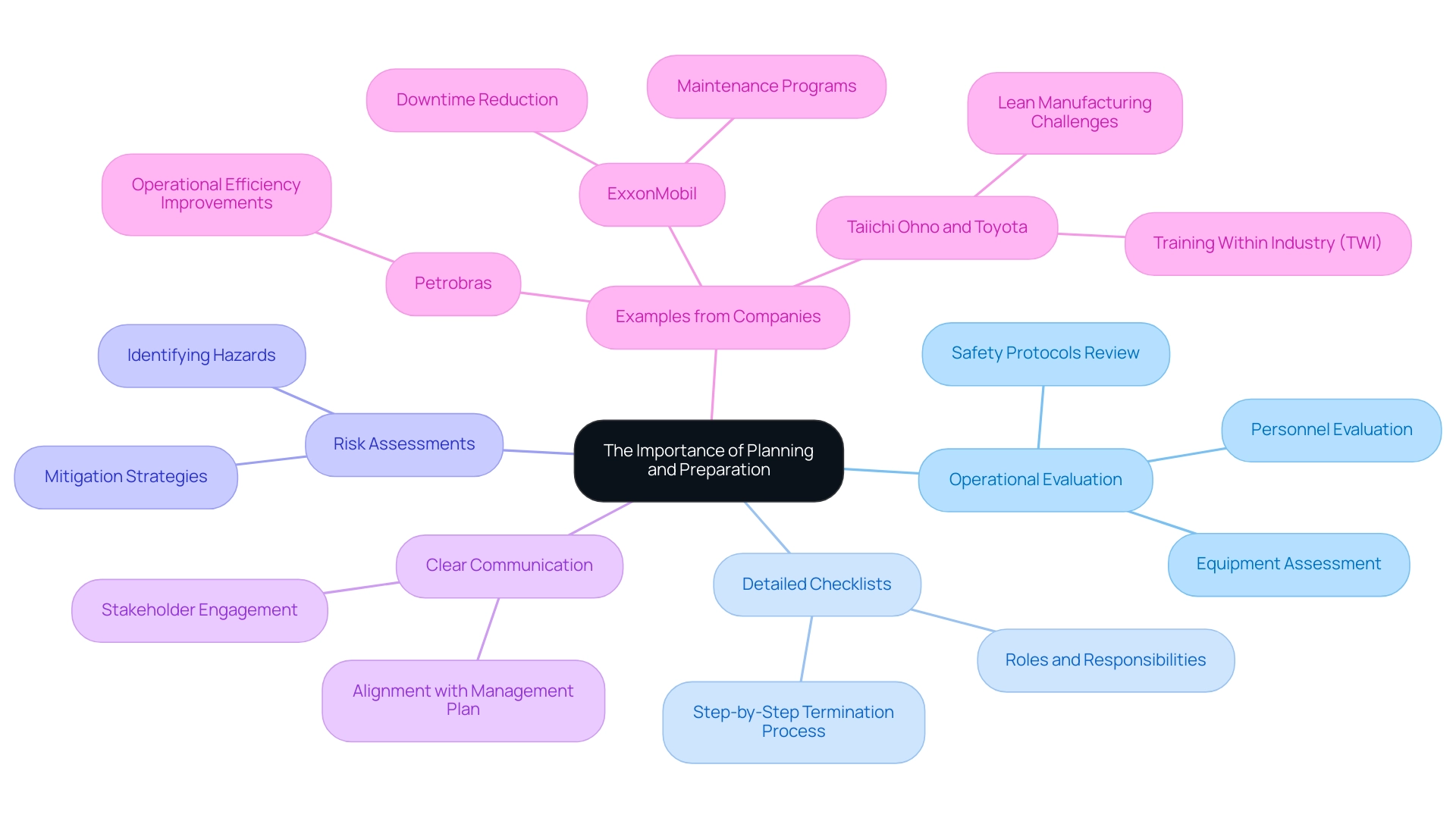

Effective planning for plant shutdown and turnaround management encompasses a thorough evaluation of all operational facets—equipment, personnel, and safety protocols. Given that equipment failure accounts for 80% of unplanned downtime in manufacturing, a meticulous approach is essential. As Engin Mustafa states, "The briefing saves busy executives and researchers hours of reading time by selecting only the very best, most pertinent information and presenting it in a condensed and easy-to-digest format," highlighting the importance of concise and relevant planning.

Begin by developing a detailed checklist that outlines each step of the termination process, ensuring that every team member comprehends their specific roles and responsibilities. This preparation is essential in reducing risks associated with plant shutdown and turnaround management. Conducting rigorous risk assessments is crucial for plant shutdown and turnaround management, as this proactive approach helps in identifying potential hazards and facilitates the establishment of effective mitigation strategies.

Additionally, consistent and clear communication with all stakeholders is essential to maintain alignment with the plant shutdown and turnaround management plan and ensure preparedness for the impending changes. Companies like ExxonMobil and Petrobras exemplify how strategic maintenance programs, through the integration of maintenance scheduling and planning, can significantly reduce downtime and enhance operational efficiency. The initial challenges faced by Taiichi Ohno and Toyota in the 1950s also highlight the significance of fundamental stability in lean manufacturing, demonstrating that efficient plant shutdown and turnaround management is essential for successful facility closures.

Implementing these practices not only fosters safety but also enhances overall facility performance.

Executing the Shutdown: Best Practices

In the execution of plant shutdown and turnaround management, adherence to a set plan is essential; however, it is equally important to retain a level of adaptability to handle unexpected situations effectively. Compliance with safety protocols is not just a regulatory requirement but a vital practice to safeguard both personnel and equipment. Eckem William Sithole emphasizes the complexity of operational metrics, stating,

Our measure of facility availability is not consistent with reality.

This emphasizes the crucial concern that availability statistics frequently conceal the true uptime performance, highlighting the necessity for careful monitoring during downtimes. To ensure smooth operations, assemble a dedicated team tasked with monitoring progress and swiftly addressing any issues that arise. Regular updates should be communicated to all stakeholders, fostering transparency and collaboration throughout the closure process.

Furthermore, utilizing complex modeling software can clarify the relationships between reliability, availability, and production capacity, enabling better reconciliation of metrics. Thorough documentation of each step taken facilitates a comprehensive review post-plant shutdown and turnaround management, allowing for insights that can improve future operations. Implementing these best practices is essential for successful termination execution in 2024 and beyond.

Post-Shutdown Review and Continuous Improvement

Post-shutdown reviews are critical for optimizing plant shutdown and turnaround management processes. To effectively utilize this time, begin with a comprehensive evaluation of the entire operation, engaging all team members involved to gather diverse feedback. This collaborative approach is essential for identifying both successes and areas requiring improvement.

Utilizing real-time analytics via our client dashboard, you can evaluate data gathered during the pause to assess its effect on efficiency and financial performance. Given that unplanned downtime costs the global process industries approximately $1 trillion annually, this analysis underscores the urgent need for continuous improvement practices that mitigate such costs. Document key lessons learned and operationalize this knowledge throughout your organization to cultivate a culture of continuous improvement.

With recent trends indicating maintenance planners concentrating on shorter outages for specific units, it’s imperative to implement changes based on your findings to enhance future shutdowns and restarts. As Zafar Iqbal, an electrical engineer with extensive project management experience, emphasizes, 'thorough reviews can significantly drive performance improvements.' By adopting a proactive approach to plant shutdown and turnaround management through post-shutdown evaluations and implementing strategies informed by real-time analytics and operational insights, organizations can not only mitigate risks but also enhance overall operational effectiveness in subsequent turnarounds.

Furthermore, our commitment to developing strong lasting relationships with our clients ensures that we support a shortened decision-making cycle, allowing your team to take decisive actions that preserve business integrity and drive performance.

Conclusion

Navigating the complexities of plant shutdowns and turnarounds is essential for organizations aiming to enhance their operational efficiency and financial performance. By focusing on thorough assessments, strategic planning, and best practices during execution, stakeholders can significantly improve their approach to these critical processes. Recognizing the importance of leveraging real-time analytics and continuous feedback allows for data-driven decision-making that mitigates risks and capitalizes on opportunities.

The structured phases of shutdown and turnaround management—assessment, planning, execution, and review—are not merely procedural steps; they form a comprehensive framework that empowers organizations to optimize their operations. Effective planning and preparation can significantly reduce unplanned downtime, while adherence to best practices during execution ensures that operations remain smooth and compliant with safety protocols.

Ultimately, the post-shutdown review process is vital for continuous improvement, enabling organizations to learn from each experience and refine their strategies for future initiatives. By fostering a culture of collaboration and leveraging insights gained from real-time analytics, companies can drive performance improvements that lead to sustainable growth. Embracing these principles positions organizations to thrive in an ever-evolving industrial landscape, where strategic foresight and adaptability are key to success.

Frequently Asked Questions

What are plant shutdown and turnaround management?

Plant shutdown and turnaround management are processes addressing maintenance needs, upgrades, or financial restructuring. A turnaround specifically aims to revitalize an underperforming operation.

Why is understanding plant shutdown and turnaround management important for stakeholders?

Comprehending these concepts is crucial for stakeholders as it directly influences operational efficiency and financial stability.

What recent trends are influencing vegetation management?

The focus is shifting towards streamlined decision-making and real-time analytics, with significant developments in energy production capabilities, such as the construction of large nuclear reactors.

How can a decision matrix benefit plant shutdown and turnaround management?

Utilizing a decision matrix can enhance performance by shortening the decision-making cycle, allowing teams to act quickly and preserve business health.

What role do inspections play in oil and gas refineries during plant shutdowns?

Inspections are necessary to ensure compliance and safety during closures, emphasizing the importance of thorough evaluations.

What is the significance of real-time analytics in plant shutdown and turnaround management?

Real-time analytics help organizations track performance and make data-driven decisions, which are essential for successful management initiatives.

How can autonomous systems and machine learning improve maintenance efficiency?

Integrating these technologies can significantly enhance maintenance efficiency and reduce costs, facilitating sustainable growth.

What are the key phases in plant shutdown and turnaround management?

The key phases include Assessment, Planning, Execution, and Review.

What is involved in the Assessment phase?

This phase involves evaluating the current functional and financial status of the plant, identifying strengths and weaknesses, and leveraging real-time analytics for data-driven decisions.

What should be included in the Planning phase?

A comprehensive plan should encompass timelines, resource allocation, and risk management strategies, ensuring all decisions are based on accurate information.

What is crucial during the Execution phase?

Carrying out activities according to the established plan while maintaining clear communication among stakeholders is vital for addressing challenges.

What is the purpose of the Review phase?

The Review phase involves evaluating the entire process post-execution to identify successes and areas for improvement, utilizing findings to drive ongoing enhancements.

How can organizations prevent scope creep during planning?

Implementing a cutoff date for integrating new work into the closing schedule helps manage scope creep and maintain schedule integrity.