Overview

Best practices for supply chain cost reduction strategies underscore the critical role of:

- Strategic planning

- Technology integration

- Supplier collaboration

in enhancing operational efficiency and profitability for CFOs. By leveraging data analytics, implementing lean practices, and nurturing robust supplier relationships, organizations can significantly lower logistics expenses and bolster overall financial performance. This approach not only ensures a competitive advantage but also positions companies favorably in a complex market landscape.

Introduction

In the intricate world of supply chain management, cost reduction stands out as a pivotal strategy for CFOs aiming to enhance profitability and operational efficiency. Given that supply chain expenses can comprise a substantial portion of total costs, grasping the nuances of cost management is essential.

This article explores the multifaceted approaches that finance leaders can adopt:

- Leveraging advanced technologies such as AI and automation

- Nurturing robust supplier relationships

- Optimizing inventory practices

By examining proven strategies and innovative solutions, organizations can not only streamline operations but also position themselves for sustainable growth in an increasingly competitive landscape.

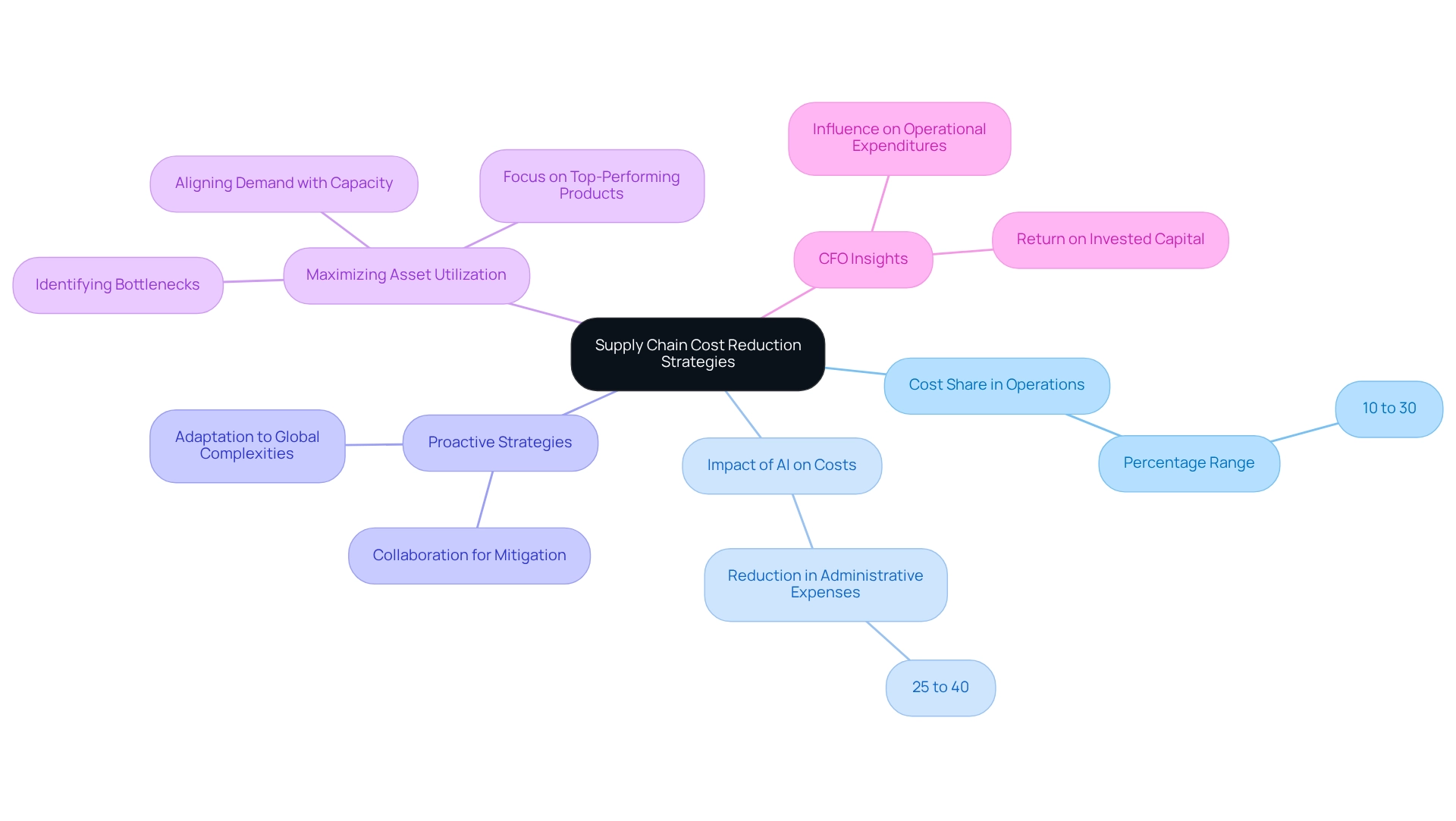

Understanding Supply Chain Cost Reduction: A CFO's Perspective

Supply logistics expenses represent a significant share of overall operational expenditures for many organizations, frequently varying from 10% to 30% of total expenses. For CFOs, implementing is essential not only for improving profitability but also for boosting operational efficiency and enhancing customer satisfaction. By carefully examining expense factors and grasping the financial consequences of logistical decisions, CFOs can make strategic choices that align with their company's goals.

In today's intricate and worldwide market, where shipping delays and the demand for adaptability are common, the significance of supply chain cost reduction strategies in logistics management cannot be emphasized enough. A recent study suggests that utilizing artificial intelligence can decrease administrative expenses by 25% to 40%, highlighting the capability of technology to optimize operations and lower expenditures.

Moreover, expert opinions emphasize that implementing supply chain cost reduction strategies in logistics necessitates a proactive approach. Joseph D'Souza, founder of ElectroIQ, asserts that in the face of global complexities, organizations must adapt their supply chain cost reduction strategies to stay competitive and efficient. This aligns with Transform Your Small/Medium Enterprise's commitment to identifying underlying organizational issues and collaboratively creating plans to mitigate weaknesses, allowing firms to reinvest in key strengths.

Focusing on maximizing asset utilization can significantly improve operational efficiency and competitiveness. A case study titled 'Maximize Asset Utilization' illustrates how businesses can enhance productivity and profitability by identifying bottlenecks and aligning demand with capacity through Throughput's AI-powered tools. The outcome of this approach demonstrates that by concentrating on top-performing products and key customers, organizations can improve customer satisfaction and overall financial health.

CFOs have observed that supply chain cost reduction strategies, through efficient management of procurement expenses, directly influence operational expenditures, enabling enhanced resource distribution and better financial well-being. Transform Your Small/Medium Business's pragmatic approach to data testing ensures that every hypothesis is evaluated to deliver maximum return on invested capital in both the short and long term. As the landscape continues to evolve, embracing innovative supply chain cost reduction strategies will be essential for sustaining a competitive advantage and ensuring long-term growth.

Top Strategies for Effective Supply Chain Cost Reduction

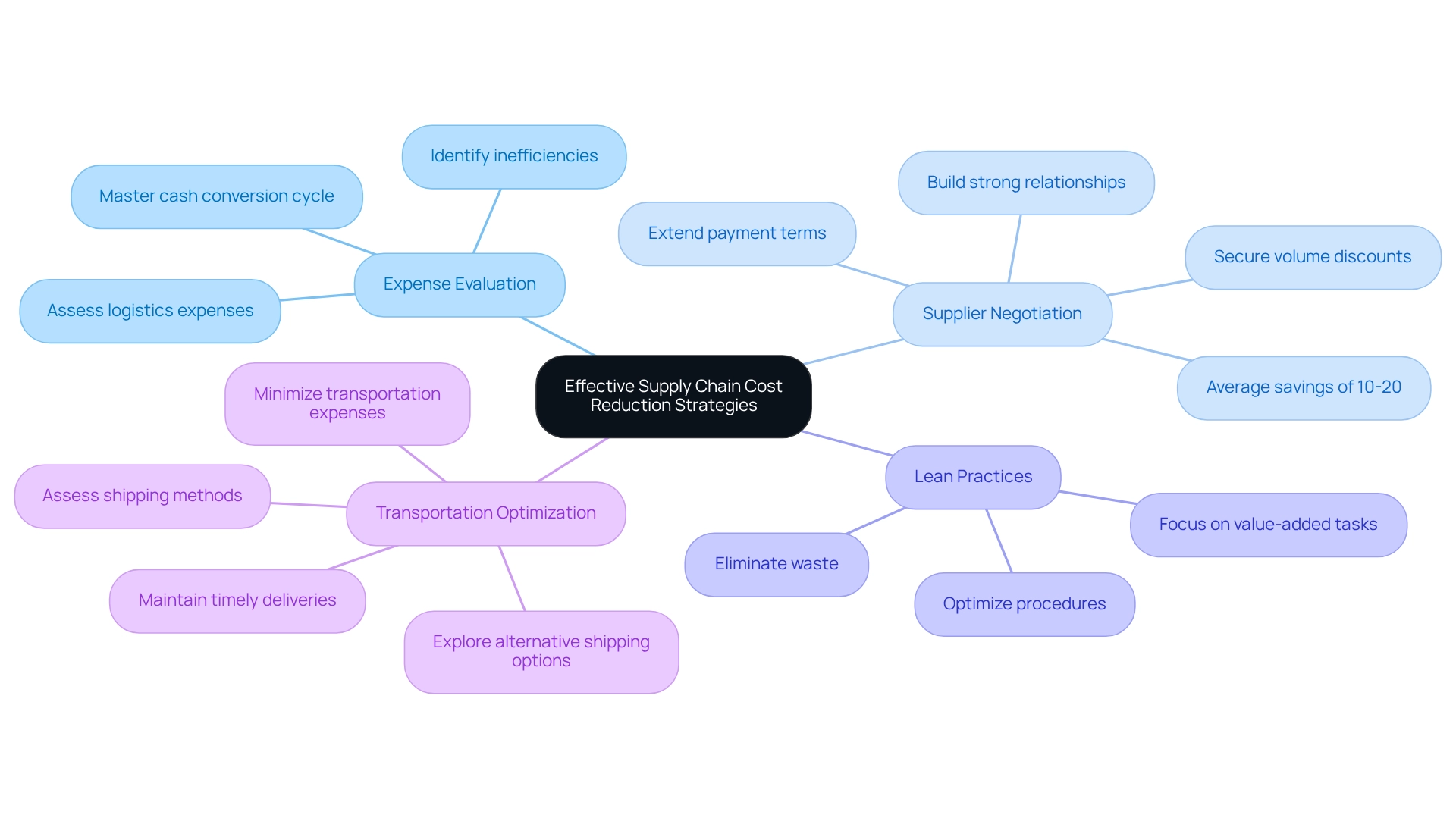

- Perform a Thorough Expense Evaluation: Consistently assessing logistics expenses is essential for recognizing major expense factors, including transportation, storage, and inventory handling. A comprehensive financial analysis allows companies to identify inefficiencies and opportunities for savings by implementing . The U.S. Bureau of Labor Statistics anticipates a 30% increase in logistics jobs from 2020 to 2030, highlighting the rising need for skilled experts who can improve supply chain efficiency through thorough financial analysis. Furthermore, mastering the cash conversion cycle through strategic expense analysis can significantly enhance overall business performance, as detailed in our product 'Mastering the Cash Conversion Cycle: 20 Strategies for Optimal Business Performance.'

- Negotiate with Suppliers: Building strong relationships with suppliers is essential for negotiating better terms. This can include securing volume discounts or extending payment terms, which can significantly impact cash flow. Effective supplier negotiations can result in average savings of 10-20% on purchasing expenses, underscoring the significance of supply chain cost reduction strategies and strategic alliances in expense reduction. Streamlined decision-making during these negotiations can further enhance cash flow management and operational efficiency, supported by our client dashboard for real-time analytics.

- Implement Lean Practices: Adopting lean methodologies helps eliminate waste and improve efficiency throughout . By optimizing procedures and concentrating on value-added tasks, companies can use supply chain cost reduction strategies to decrease expenses while improving service delivery. Lean practices not only optimize operations but also contribute to a culture of continuous improvement, which is vital for operationalizing turnaround lessons and maintaining competitive advantage.

- Optimize Transportation: Assessing shipping methods and routes is essential for minimizing transportation expenses without compromising service levels. With 65% of customers likely to abandon a retailer after two to three late deliveries, maintaining timely and accurate deliveries is paramount for customer retention. Companies should explore alternative shipping options and consolidate shipments to achieve cost savings while ensuring customer satisfaction. Continuous monitoring of transportation performance through real-time analytics, as provided by our client dashboard, can help identify further optimization opportunities that align with supply chain cost reduction strategies.

Employing data analytics is essential for supply chain cost reduction strategies, as it offers significant insights into performance metrics, allowing organizations to pinpoint areas for enhancement. As 78% of companies are exploring technology solutions to enhance operational efficiency, utilizing data-driven decision-making can lead to more informed strategies and better resource allocation. Moreover, the recent increase of global logistics visibility by 22.4% emphasizes the significance of transparency in operational processes, which can be greatly improved through efficient data analytics. Continuous performance monitoring through real-time analytics not only supports operational efficiency but also fosters relationship-building with stakeholders.

Leveraging Technology for Cost Efficiency in Supply Chains

Technology plays a pivotal role in enhancing supply chain operations. CFOs must prioritize strategies for supply chain cost reduction to drive efficiency. By implementing automation in warehousing and logistics, companies can significantly lower labor expenses while improving accuracy. This shift not only streamlines operations as part of supply chain cost reduction strategies but also minimizes human error, leading to .

However, organizations must invest in cybersecurity measures to safeguard these automated systems from potential cyberattacks.

Leveraging Artificial Intelligence (AI) for demand forecasting and inventory management is essential for minimizing excess stock and implementing supply chain cost reduction strategies. With the global AI in the logistics market projected to reach $41.23 billion by 2030, expanding at a CAGR of 38.8% from 2023 to 2030, this technology is revolutionizing how companies manage inventory and respond to market demands.

This growth is driven by the need for improved visibility and efficiency, making AI-driven supply chain cost reduction strategies a crucial component of modern logistics. Investing in integrated supply chain management software is vital for providing real-time visibility and analytics, which are essential for effective supply chain cost reduction strategies. This technology enhances decision-making capabilities, enabling CFOs to identify inefficiencies and utilize supply chain cost reduction strategies to optimize resource allocation effectively.

Furthermore, it helps to shorten the decision-making cycle during the turnaround process, allowing for decisive actions that maintain organizational health. At Transform Your Small/Medium Business, we utilize a client dashboard that provides real-time business analytics to continually assess your business health.

Investigating Blockchain Technology may lead to enhanced transparency and traceability in transaction processes. This technology helps reduce fraud and errors, fostering trust among stakeholders and ensuring compliance with regulatory standards.

Current trends indicate that organizations are increasingly focusing on automating labor-intensive activities and exploring fleet electrification opportunities. According to IHS Markit, the expense of goods sold has risen by 7% in the first half of 2022 due to disruptions in logistics, increases in material input costs, and high inflation. Adopting these technologies is not merely beneficial but necessary for maintaining a competitive advantage through effective supply chain cost reduction strategies in a challenging economic landscape.

Continuous monitoring through real-time analytics, as facilitated by our client dashboard, is essential for evaluating the success of these strategies and operationalizing lessons learned during the turnaround process.

Enhancing Supplier Collaboration to Drive Cost Savings

Building robust relationships with suppliers is essential for . CFOs can significantly enhance collaboration through the following approaches:

- Sharing Forecasts and Demand Plans: Providing suppliers with accurate forecasts enables them to align their production schedules with your needs, ultimately reducing lead times. This proactive strategy not only optimizes operations but also improves overall logistics reliability. As Brian Straight, Editor in Chief of Supply Management Review, observes, effective collaboration is essential in today’s intricate logistics environment.

- Joint Cost Reduction Initiatives: Collaborating with suppliers to identify joint cost-saving opportunities can yield substantial benefits. Initiatives like bulk purchasing agreements or shared logistics arrangements can result in significant decreases in expenses while preserving quality and service levels. Recent statistics show that over 80% of organizations encountered considerable logistical disruptions in the past two years, emphasizing the necessity for such collaborative efforts.

- Regular Communication: Establishing and maintaining open lines of communication is vital. Regular discussions help address potential issues promptly and foster a collaborative environment where both parties can work towards common goals.

- Supplier Performance Metrics: Implementing performance metrics to evaluate supplier contributions is crucial. By evaluating how vendors affect savings and overall logistics efficiency, CFOs can make knowledgeable choices regarding vendor partnerships and pinpoint areas for enhancement. The significance of these strategies is underscored by the reality that the typical delivery time for products has risen by 20% since 2020, driven by a rise in online shopping and shipping holdups. This context emphasizes that effective supplier collaboration is not just beneficial but necessary for navigating these challenges. By improving supplier cooperation, companies can not only attain prompt savings but also create a more robust supply chain for the future.

Optimizing Inventory Management for Cost Reduction

Enhancing inventory management is essential for effective . CFOs must consider the following best practices:

- Just-In-Time (JIT) Inventory: Adopting JIT inventory systems can significantly minimize holding costs and reduce excess stock. Supermarkets exemplify this approach by restocking products only after customer purchases deplete available inventory, ensuring that resources are allocated efficiently. However, the COVID-19 pandemic has prompted many leaders to consider just-in-case (JIC) systems, which focus on maintaining inventory buffers to mitigate supply chain disruptions, contrasting with JIT systems. The decision-making cycle can be shortened by leveraging real-time analytics to assess inventory levels and customer demand, allowing for more agile responses to market changes.

- ABC Analysis: Implementing ABC analysis enables companies to categorize inventory according to value and turnover rates. This method allows organizations to focus their resources on high-impact items, ensuring that the most critical products are prioritized for management and investment. Research has demonstrated that efficient ABC analysis can result in enhanced inventory turnover and lower holding expenses. By continuously monitoring these categories through real-time analytics, CFOs can make informed decisions that enhance cash flow and profitability.

- Regular Audits: Conducting regular inventory audits is essential for identifying discrepancies and maintaining accurate stock levels. This practice not only helps mitigate losses but also enhances overall inventory accuracy, which is vital for effective decision-making. Continuous improvement in these practices is key, as Mark Twain aptly stated, "Continuous improvement is better than delayed perfection." Utilizing real-time dashboards can facilitate ongoing performance monitoring, ensuring that any issues are promptly addressed.

- Technology Integration: Leveraging advanced inventory management software can automate tracking and forecasting processes, leading to improved accuracy and efficiency. For instance, the implementation of PlanetTogether's Advanced Planning and Scheduling (APS) software has resulted in a 15% reduction in inventory overhead and a 20% decrease in overtime labor expenses. This shift allows manufacturers to transition from building stock to building to ship, optimizing their operations. By integrating real-time analytics into these systems, CFOs can continuously assess business health and operational efficiency, enabling strategic adjustments as needed.

By concentrating on supply chain cost reduction strategies, CFOs can improve their inventory management methods, resulting in significant savings and enhanced operational efficiency. Moreover, a recent statistic shows that a decline in raw material expenses can further aid in overall expenditure reduction strategies, making it essential for CFOs to remain informed and flexible in their methods.

Implementing Continuous Improvement Practices in Supply Chains

Ongoing enhancement is essential for maintaining efficiency in logistics, particularly in the evolving landscape of 2025. CFOs can implement several strategies to promote expense reduction and enhance operational effectiveness:

- Kaizen Methodology: Embrace the Kaizen approach, which nurtures a culture of gradual enhancements across all logistics processes. This methodology has proven successful in boosting efficiency, with organizations reporting significant productivity gains through supply chain cost reduction strategies.

- Employee Training: Prioritize investment in comprehensive training programs that empower employees to identify inefficiencies and propose actionable improvements. Studies indicate that effective employee training can contribute significantly to supply chain cost reduction strategies, yielding a 20% increase in operational efficiency. This highlights its critical role in logistics success. However, it is concerning that only 40% of businesses are currently reskilling employees as a talent strategy, a notable decline from 70% in 2020. This drop could lead to skills gaps and challenges in workforce development, underscoring the urgent need for renewed focus on employee training.

- Performance Metrics: Develop and monitor key performance indicators (KPIs) to assess progress and identify areas for further enhancement. Metrics such as supply chain cost reduction strategies (35%), Production Service Rate (29%), and Inventory Turn (28%) are vital for evaluating performance and promoting ongoing enhancement. According to AJG Transport, these daily performance indicators are essential for operational success. By rigorously testing hypotheses and measuring investment returns, CFOs can ensure their supply chain cost reduction strategies yield maximum returns on invested capital.

- Feedback Loops: Establish robust feedback mechanisms to gather insights from employees and suppliers. This practice fosters a culture of continuous improvement and ensures that the logistics network remains adaptable and responsive to evolving market demands through the implementation of supply chain cost reduction strategies. Given that the average time to deliver a product from supplier to customer has increased by 20% since 2020, enhancing these processes is more urgent than ever. through real-time analysis can strengthen relationships and apply insights gained from supply chain cost reduction strategies.

Moreover, the global AI in the logistics market is projected to reach $41.23 billion by 2030, expanding at a CAGR of 38.8%. This underscores the increasing necessity for efficiency in logistics and the pivotal role of technology in advancing supply chain cost reduction strategies. By adopting these methods, CFOs can adeptly navigate the complexities of management, ultimately driving sustainable growth and improved financial performance.

Strategic Planning and Risk Management in Supply Chain Cost Reduction

are crucial for attaining effective supply chain cost reduction strategies in logistics. CFOs should focus on the following key strategies:

- Conduct Risk Evaluations: Regular risk evaluations are essential for identifying weaknesses within the distribution network. By evaluating potential disruptions—such as supplier failures or logistical challenges—businesses can develop robust contingency plans that minimize financial impact and ensure continuity.

- Align Logistics Strategy with Business Goals: It is crucial that logistics initiatives are closely aligned with the overall business objectives and financial targets. This alignment not only enhances operational efficiency but also drives profitability. Firms investing in sustainable logistics practices have experienced an average earnings rise of 23%, based on a survey by EY, emphasizing the financial advantages of such alignment.

- Scenario Planning: Participating in scenario planning enables organizations to foresee market changes and their possible impacts on expenses related to resources. By preparing for various outcomes, businesses can utilize supply chain cost reduction strategies to make informed decisions that safeguard against unexpected financial strains. Notably, with a total of 5.1 million twenty-equivalent units (TEUs) expected to be added to the fleet in 2023-24, understanding capacity dynamics is crucial for effective planning. Historical data from Clarksons indicates that the average annual fleet growth was 970,000 TEUs between 2001-2020, underscoring the need for proactive strategies.

- Invest in Resilience: Developing resilience within the logistics network is essential for reducing risks. This can be achieved through supply chain cost reduction strategies that involve diversifying suppliers and logistics options, which not only protects against disruptions but also enhances flexibility in responding to market demands. Recent surveys show that 65% of customers would leave a retailer after two to three delayed deliveries, highlighting the necessity for prompt and dependable logistics operations. Additionally, implementing code verification tools is necessary to locate and fix vulnerabilities in software, protecting supply chains against cyber threats.

- Streamlined Decision-Making and Real-Time Analytics: To further improve supply chain cost reduction strategies, CFOs at Transform Your Small/ Medium Enterprise should utilize real-time analytics to continuously monitor organizational health. By utilizing client dashboards that provide real-time business analytics, organizations can make swift, informed decisions that preserve business integrity during turnaround processes. This method not only aids in efficient expense management but also promotes a culture of agility and responsiveness within the logistics network, aligning with the 'decide and execute' framework.

By applying these strategies, CFOs can effectively maneuver through the complexities of logistics management, ensuring both expense reduction and sustainable growth in an increasingly volatile market.

The Benefits of Effective Supply Chain Cost Reduction Strategies

Implementing offers numerous benefits that can significantly enhance a company's financial performance and operational capabilities.

- Enhanced Profit Margins: Decreasing procurement expenses directly correlates with improved profit margins. Businesses that have embraced sustainable logistical initiatives report an average earnings increase of 23%, underscoring the financial advantages of strategic cost management.

- Enhanced Operational Efficiency: Streamlining logistics processes not only accelerates turnaround times but also elevates service levels. By leveraging real-time analytics, organizations can make swift decisions that enhance responsiveness to customer demands, fostering a more agile organizational environment. This aligns with the 'Decide & Execute' methodology, empowering teams to take decisive action.

- Enhanced Customer Satisfaction: A cost-effective logistics system enables organizations to offer competitive pricing and superior service, which are crucial drivers of customer satisfaction. Satisfied customers are more likely to remain loyal, contributing to long-term profitability.

- Sustainable Growth: Continuous enhancement of supply chain expenses allows companies to allocate resources toward growth initiatives. This proactive approach ensures that organizations stay competitive in an ever-evolving market landscape. By operationalizing lessons learned from past performance, companies can refine their strategies for better outcomes, reflecting the 'Update & Adjust' strategy.

The significance of these strategies is further illustrated by a case study on the repercussions of slow responses to market trends. Retailers with outdated inventory systems often grapple with excess stock in declining categories while missing out on trending products, ultimately undermining profitability. This disconnect highlights the necessity for effective inventory management to align with market demands. By adopting supply chain cost reduction strategies and utilizing real-time analytics, companies can avoid such pitfalls and position themselves for sustainable success.

According to AJG Transport, some of the most critical daily performance indicators include Expense Reduction (35%), Production Service Rate (29%), Inventory Turn (28%), and Production Time (27%). This underscores that focusing on expense reduction is not merely advantageous but essential for enhancing overall financial performance. Furthermore, the initial 'Identify & Plan' phase is vital for recognizing underlying business issues and collaboratively creating a plan to address weaknesses, ensuring a comprehensive approach to cost reduction.

Conclusion

Implementing effective cost reduction strategies within supply chain management is essential for CFOs seeking to enhance profitability and operational efficiency. This article outlines several key approaches:

- Conducting comprehensive cost analyses

- Fostering strong supplier relationships

- Optimizing inventory management

- Leveraging technology

- Prioritizing continuous improvement

Each of these strategies plays a pivotal role in identifying inefficiencies, reducing expenses, and ultimately driving sustainable growth.

Moreover, by embracing advanced technologies such as AI and automation, organizations can streamline operations and significantly reduce costs. Additionally, enhancing collaboration with suppliers leads to better terms and shared savings, while optimizing inventory practices ensures resources are allocated efficiently. The emphasis on continuous improvement creates a culture that is agile and responsive to market demands, further contributing to operational excellence.

In conclusion, the benefits of effective supply chain cost reduction strategies are far-reaching, impacting profit margins, operational efficiency, and customer satisfaction. Organizations that prioritize these strategies not only position themselves for immediate financial gains but also lay the groundwork for long-term success in a competitive landscape. As the market continues to evolve, CFOs must remain proactive in adopting innovative solutions to navigate challenges and seize opportunities for growth.

Frequently Asked Questions

What percentage of total expenses do supply logistics expenses typically represent for organizations?

Supply logistics expenses usually account for 10% to 30% of total operational expenditures for many organizations.

Why is it important for CFOs to implement supply chain cost reduction strategies?

Implementing effective supply chain cost reduction strategies is crucial for CFOs as it improves profitability, boosts operational efficiency, and enhances customer satisfaction.

How can artificial intelligence impact supply chain costs?

Utilizing artificial intelligence can decrease administrative expenses by 25% to 40%, which highlights its potential to optimize operations and lower expenditures.

What approach is recommended for implementing supply chain cost reduction strategies?

A proactive approach is recommended, as organizations must adapt their supply chain cost reduction strategies to stay competitive and efficient amidst global complexities.

What is the significance of maximizing asset utilization in supply chain management?

Focusing on maximizing asset utilization can significantly improve operational efficiency and competitiveness, leading to enhanced productivity and profitability.

How can businesses enhance productivity and profitability according to the case study 'Maximize Asset Utilization'?

Businesses can enhance productivity and profitability by identifying bottlenecks and aligning demand with capacity using AI-powered tools.

How do supply chain cost reduction strategies influence operational expenditures?

Efficient management of procurement expenses through supply chain cost reduction strategies directly influences operational expenditures, enabling better resource distribution and improved financial well-being.

What are some key strategies for reducing supply chain costs?

Key strategies include performing a thorough expense evaluation, negotiating with suppliers, implementing lean practices, and optimizing transportation methods.

What role does data analytics play in supply chain cost reduction?

Data analytics provides significant insights into performance metrics, helping organizations identify areas for enhancement and enabling data-driven decision-making for better resource allocation.

Why is transparency in operational processes important for supply chain management?

Transparency in operational processes is essential as it improves global logistics visibility and fosters relationship-building with stakeholders, ultimately enhancing operational efficiency.