Introduction

In the competitive landscape of quarry management, understanding and optimizing cost structures is not just beneficial—it's essential for survival. With a mix of fixed and variable costs impacting the bottom line, CFOs must adopt a strategic approach to identify inefficiencies and implement targeted cost reduction strategies.

From leveraging advanced technologies to embracing sustainable practices, the opportunities for enhancing profitability while minimizing environmental impact are abundant. This article delves into actionable insights and effective strategies that can transform cost management in quarry operations, ensuring that organizations not only thrive in the present but are also well-prepared for future challenges.

Understanding Cost Structures in Quarry Operations

To achieve substantial reductions in quarry operations, a comprehensive understanding of the financial structure is paramount. Expenses can be classified into:

- Fixed expenses—such as equipment depreciation and salaries

- Variable expenses, which encompass fuel and maintenance expenditures

Start this procedure by carefully collecting financial statements and functional data to clearly identify these expense elements.

Conduct a thorough analysis of historical data to uncover trends and patterns, allowing for the categorization of expenses into manageable segments. This foundational understanding not only highlights the financial landscape of your operations but also serves as a critical basis for formulating targeted cost reduction strategies in quarry operations. For instance, a recent study suggested that altering haul road surfaces could decrease fuel usage by almost 20%, demonstrating the potential effect of adjustments on variable expenses.

Additionally, a case study on five configurations of quarrying equipment demonstrates how varying operational parameters can significantly influence expenses, with one configuration yielding a 2% higher intermediate product due to a more efficient crushing system. Furthermore, expert insights from Michał Patyk at AGH University of Krakow emphasize the significance of optimizing transport routes and material processing, stating,

Alternative W3 involves preliminary crushing of material in a stationary crusher, with the longest transport routes, and the optimum proportion of intermediate product in the seam.

Furthermore, taking into account that 10% of the excavated material was designated as spoils due to karst inclusions, comprehending the physical and mechanical properties of materials is essential for effective financial management.

By concentrating on both fixed and variable expenses, and incorporating these insights, CFOs can develop informed cost reduction strategies in quarry operations that enhance efficiency, boost profitability, and promote environmental sustainability in resource management.

Effective Strategies for Cost Reduction in Quarry Management

Implementing effective cost reduction strategies in quarry operations necessitates a comprehensive approach tailored to the unique challenges faced in quarry management. Here are several strategies to consider:

-

Optimize Resource Allocation: Begin by assessing labor and equipment utilization to ensure maximum efficiency.

Implementing sophisticated scheduling systems can significantly minimize downtime, enhancing overall productivity. Recent case studies suggest that successful resource allocation directly correlates with decreased operational expenses, emphasizing the importance of implementing cost reduction strategies in quarry operations.

-

Negotiate Supplier Contracts: Regularly review and renegotiate contracts with suppliers to secure more favorable rates or bulk purchase discounts.

Building solid connections with various suppliers can offer leverage during discussions, ultimately resulting in substantial savings.

-

Implement Preventative Maintenance: Transition from a reactive maintenance approach to a preventative one.

This shift can prolong equipment lifespan and drastically reduce unforeseen repair expenses, which are often a drain on resources.

Investing in training for staff to recognize early signs of equipment wear can further optimize maintenance efforts.

-

Streamline Operations: Conduct a thorough evaluation of your workflows to identify bottlenecks that hinder efficiency.

Streamlining processes can lead to enhanced productivity.

Additionally, consider cross-training employees, which can increase flexibility in labor allocation and ensure that activities are not disrupted by the absence of key personnel.

-

Reduce Waste: Perform waste audits to pinpoint areas where materials are being squandered.

Implementing cost reduction strategies in quarry operations not only minimizes loss but also decreases costs while aligning with sustainability goals.

As highlighted in a recent study, utilizing natural extraction materials can achieve significant carbon removal potential of up to 2.2 tonnes of CO2 equivalent per hectare per year, showcasing an opportunity to reduce environmental impact while cutting costs.

Integrating strategies such as Failure Modes and Effects Analysis (FMEA) can systematically identify and address potential failure points in extraction operations, preemptively mitigating risks and improving reliability.

This approach not only enhances operational efficiency but also builds customer trust, emphasizing the importance of investment in training and process re-engineering.

In the words of industry experts,

A periodic review of strategic initiatives in light of emerging trends is essential to maintain competitive positioning.

This approach is essential in navigating the complexities of resource management in 2024 and beyond.

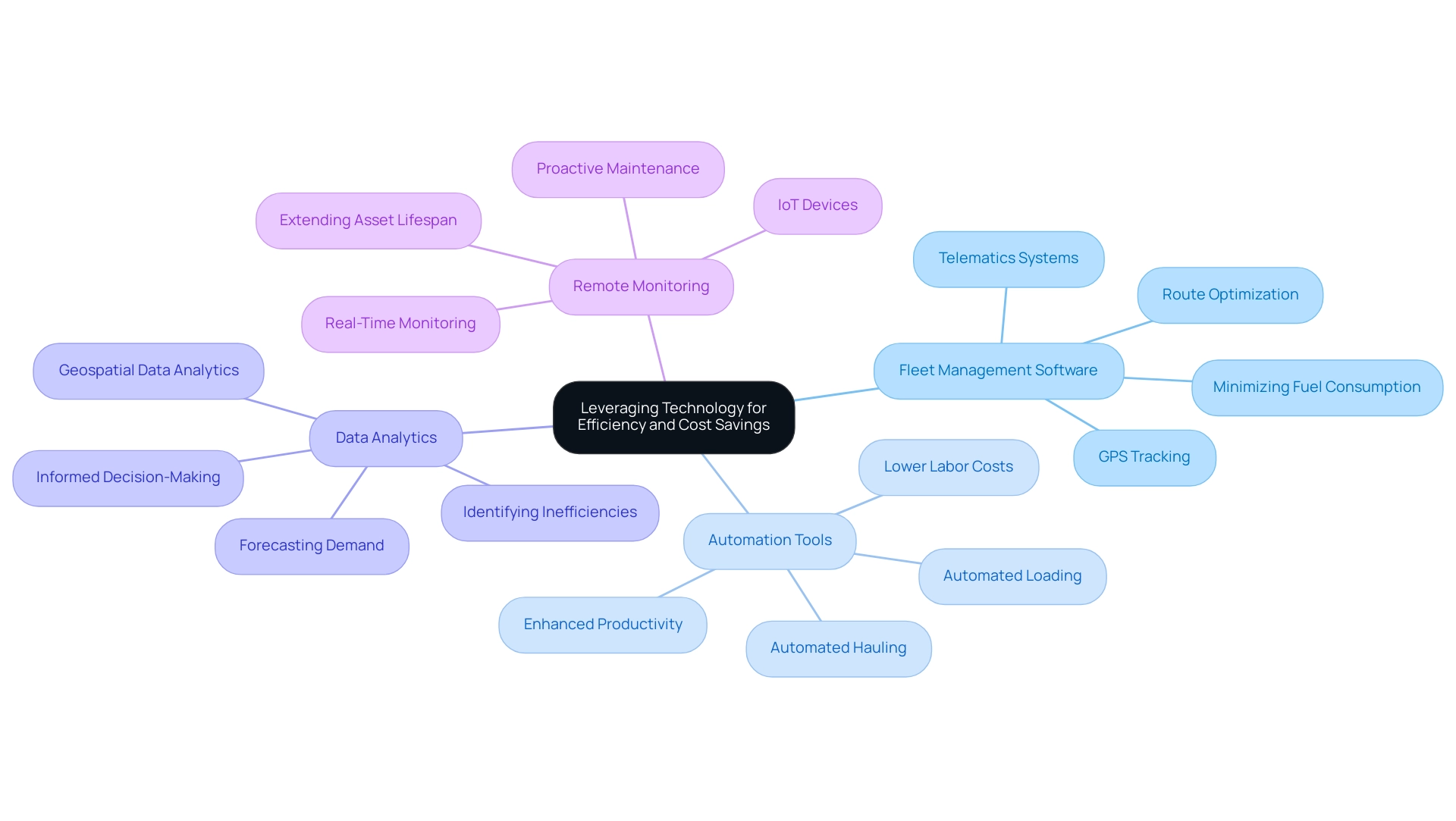

Leveraging Technology for Enhanced Efficiency and Cost Savings

Incorporating advanced technology into quarry activities is essential for implementing cost reduction strategies in quarry operations while ensuring safety. As the Minerals Council of Australia reports, over 77% of jobs in the mining sector will be transformed by technological innovations in the next five years, potentially boosting productivity by as much as 23%. Safety continues to be a fundamental aspect of quarrying activities, with the implementation of wearable technology and advanced monitoring systems improving worker safety and efficiency.

Here are key technologies to consider for optimizing operations:

- Fleet Management Software: Implement GPS tracking and telematics systems to monitor vehicle usage, optimize routes, and minimize fuel consumption. This software not only improves efficiency but also aligns with sustainability goals.

- Automation Tools: Utilize automated systems for repetitive tasks such as loading and hauling. Implementing cost reduction strategies in quarry operations can significantly lower labor costs while enhancing productivity through more consistent operations.

- Data Analytics: Utilize data analytics, including geospatial data analytics, to gain deeper insights into performance. By identifying inefficiencies and accurately forecasting demand, you can make informed decisions that implement cost reduction strategies in quarry operations and enhance sustainability.

- Remote Monitoring: Utilize IoT devices to facilitate real-time monitoring of equipment performance. This proactive approach to maintenance not only reduces downtime but also extends the lifespan of your assets, thereby implementing cost reduction strategies in quarry operations and lowering overall operational costs. Additionally, companies like Brunel are committed to being carbon-neutral and have implemented ESG strategies that demonstrate how technology can enhance sustainability practices in mining.

The implementation of these technologies is not merely a trend but a strategic imperative for stone extraction sites aiming to remain competitive in an evolving landscape.

Incorporating Sustainable Practices to Reduce Costs

Embracing sustainable practices not only contributes to environmental stewardship but also enables the implementation of cost reduction strategies in quarry operations, unlocking significant financial benefits. CFOs should consider the following strategies:

-

Reduce Energy Consumption: Invest in energy-efficient equipment and implement best practices to minimize energy expenses.

Conducting thorough energy audits will help identify inefficiencies and areas ripe for improvement.

-

Water Management: Streamline water usage across operations to minimize expenses associated with sourcing and treating water.

Exploring rainwater harvesting systems can provide a sustainable solution to water management challenges.

-

Recycling and Waste Reduction: Establish robust recycling initiatives for materials and waste generated during quarrying activities.

This approach not only decreases disposal costs but also opens avenues for additional revenue streams.

-

Sustainable Sourcing: Partner with suppliers who prioritize sustainable practices.

Implementing cost reduction strategies in quarry operations can enhance your brand's reputation and attract customers who are increasingly environmentally conscious, as these steps represent a strategic shift towards sustainability that aligns with industry trends. The mining company's accumulation of ZAR 200 million in debt due to losses and lawsuits underscores the urgent need to adopt sustainable practices to mitigate financial risks. As the mining industry encounters substantial financial challenges—highlighted by the recent report indicating a US$845 billion revenue with a 44% decline in net profit—adopting eco-friendly practices can play a crucial role in implementing cost reduction strategies in quarry operations and ensuring long-term sustainability.

Furthermore, the merging of industry and eco-conscious practices is defining leading aggregate producers, making sustainability a competitive advantage. As Babalwa Kafu-Quvane points out, addressing the ethical implications of quarry operations, including land degradation and pollution, is crucial for maintaining a responsible business model. By focusing on sustainability, CFOs can lead their companies toward a more resilient and profitable future in the mining landscape.

Continuous Improvement: Monitoring and Adapting Cost Reduction Strategies

To maintain the effectiveness of cost reduction strategies, it is essential to implement a robust system for continuous improvement using real-time analytics and streamlined decision-making:

- Regular Performance Reviews: Conduct periodic evaluations of both financial and functional performance to assess the effectiveness of your expense reduction initiatives. Utilizing real-time business analytics through our client dashboard allows for timely adjustments, ensuring that strategies remain aligned with the ever-evolving market landscape, particularly as industries anticipate significant supply chain challenges in 2025, where achieving revenue of $10 billion or more is a priority.

- Feedback Mechanisms: Establish organized pathways for employees to share insights and recommendations focused on improving operational efficiency and minimizing expenses. Engaging staff in this manner not only fosters a culture of continuous improvement but also empowers teams to contribute actively to the organization's success, building stronger relationships through open dialogue.

- Benchmarking: Regularly compare your quarry's performance with industry standards and best practices. This comparative analysis can reveal critical areas for enhancement and drive your organization towards achieving excellence in financial management, especially through implementing cost reduction strategies in quarry operations, further supported by real-time performance data.

- Adaptation and Flexibility: Embrace a proactive approach by being ready to adjust your strategies in response to shifting market conditions or the introduction of new technologies. Regularly reviewing and improving your cost reduction strategies in quarry operations is essential for maintaining their relevance and effectiveness. As highlighted in recent studies, companies that balance security protocols with employee efficiency can significantly elevate their operational performance, a balance achieved through the effective use of user-friendly tools and ongoing training.

Furthermore, the case study named "Overcoming Power Dynamics in Partnerships" demonstrates the significance of open communication and defined roles in promoting strategic growth, which corresponds with the theme of ongoing enhancement in financial management.

By focusing on these principles and utilizing the Decide & Execute framework, organizations can not only realize immediate cost benefits but also position themselves for sustainable growth in the long run, leveraging AI and machine learning to revolutionize operations.

Conclusion

Understanding and optimizing cost structures is crucial in the quarry management sector, where both fixed and variable costs significantly impact profitability. By analyzing financial data and identifying inefficiencies, CFOs can formulate targeted cost reduction strategies that enhance operational performance. Implementing effective resource allocation, negotiating supplier contracts, and adopting preventative maintenance practices are just a few of the strategies that can lead to substantial savings.

Integrating advanced technology, such as fleet management software and data analytics, further streamlines operations and boosts productivity. Additionally, embracing sustainable practices not only reduces costs but also aligns with the growing demand for environmentally responsible operations. By focusing on energy efficiency, water management, and recycling initiatives, organizations can mitigate financial risks while enhancing their reputational standing in the industry.

Continuous improvement is essential for maintaining the effectiveness of these cost reduction strategies. Regular performance reviews, feedback mechanisms, and benchmarking against industry standards allow organizations to adapt and refine their approaches in response to changing market conditions. By fostering a culture of continuous improvement and leveraging innovative technologies, quarry operations can thrive, ensuring long-term sustainability and profitability in a competitive landscape.

Frequently Asked Questions

What are the two main categories of expenses in quarry operations?

The two main categories of expenses in quarry operations are fixed expenses, such as equipment depreciation and salaries, and variable expenses, which include fuel and maintenance expenditures.

How can financial statements and functional data help in cost reduction?

Financial statements and functional data help identify expense elements clearly, allowing for a thorough analysis of historical data to uncover trends and patterns, which is essential for categorizing expenses and formulating targeted cost reduction strategies.

What example demonstrates the impact of operational adjustments on variable expenses?

A recent study suggested that altering haul road surfaces could decrease fuel usage by almost 20%, highlighting how adjustments can significantly affect variable expenses.

How can operational parameters influence quarrying expenses?

A case study on five configurations of quarrying equipment showed that varying operational parameters can significantly influence expenses, with one configuration yielding a 2% higher intermediate product due to a more efficient crushing system.

What is the significance of optimizing transport routes and material processing?

Optimizing transport routes and material processing is crucial for reducing costs and improving efficiency, as emphasized by expert insights from Michał Patyk, who highlighted the benefits of preliminary crushing in a stationary crusher.

Why is understanding the physical and mechanical properties of materials important?

Understanding the physical and mechanical properties of materials is essential for effective financial management, especially considering that 10% of the excavated material was designated as spoils due to karst inclusions.

What are some strategies for implementing cost reduction in quarry operations?

Strategies for cost reduction include optimizing resource allocation, negotiating supplier contracts, implementing preventative maintenance, streamlining operations, and reducing waste.

How can preventative maintenance impact quarry operations?

Transitioning to a preventative maintenance approach can prolong equipment lifespan and drastically reduce unforeseen repair expenses, which often drain resources.

What role do waste audits play in cost reduction?

Waste audits help identify areas where materials are being wasted, allowing for the implementation of strategies that minimize loss and decrease costs while aligning with sustainability goals.

What is the importance of periodic reviews of strategic initiatives in quarry management?

Periodic reviews of strategic initiatives are essential to maintain competitive positioning and navigate the complexities of resource management effectively.