Introduction

In a landscape where operational efficiency can determine the fate of an organization, mastering the intricacies of cost reduction strategies is paramount for CFOs. From optimizing inventory management to enhancing demand forecasting, each facet plays a critical role in maintaining a competitive edge. By adopting innovative approaches such as:

- Just-In-Time inventory systems

- Leveraging advanced analytics for demand predictions

- Engaging in strategic supplier negotiations

companies can unlock significant savings while improving service levels. Furthermore, the integration of technology and automation into logistics operations not only streamlines processes but also positions organizations for sustainable growth. This article delves into actionable strategies that empower CFOs to drive cost efficiency across their supply chains, ensuring they are well-equipped to navigate the complexities of today's business environment.

Optimizing Inventory Management for Cost Efficiency

Efficient inventory control is essential for matching stock levels with customer demand and applies in supply chain management to minimize unnecessary holding expenses. One powerful strategy that exemplifies cost reduction strategies in supply chain management is Just-In-Time (JIT) inventory control, which synchronizes inventory orders with production schedules to significantly reduce excess stock. This approach not only cuts down on carrying costs but also enhances cash flow, allowing organizations to allocate resources more efficiently.

In parallel, the ABC analysis categorizes inventory into three groups based on importance—A for high-value items, B for moderate-value items, and C for low-value items. This method enables businesses to concentrate their oversight efforts on the most critical stock, optimizing overall efficiency. Significantly, global stock turns averaged 5.3 over the past year, serving as a benchmark for evaluating inventory effectiveness.

With the inventory control software market expected to attain a worth of $2,191.2 million by the conclusion of 2024, businesses are increasingly embracing these technological solutions to improve their inventory approaches. As Steve Bennett, a Business Formation Expert, states, "With LLCBuddy, you're not just getting a tutorial; you're gaining a trustworthy partner for your entrepreneurial journey," emphasizing the importance of reliable partnerships in successful inventory oversight. Moreover, labor considerations such as warehouse worker salaries play a significant role in cost reduction strategies in supply chain management, making it essential for CFOs to factor these elements into their inventory management plans.

Such advancements are pivotal in enhancing efficiency, improving service levels, and maintaining a competitive edge in the supply chain landscape.

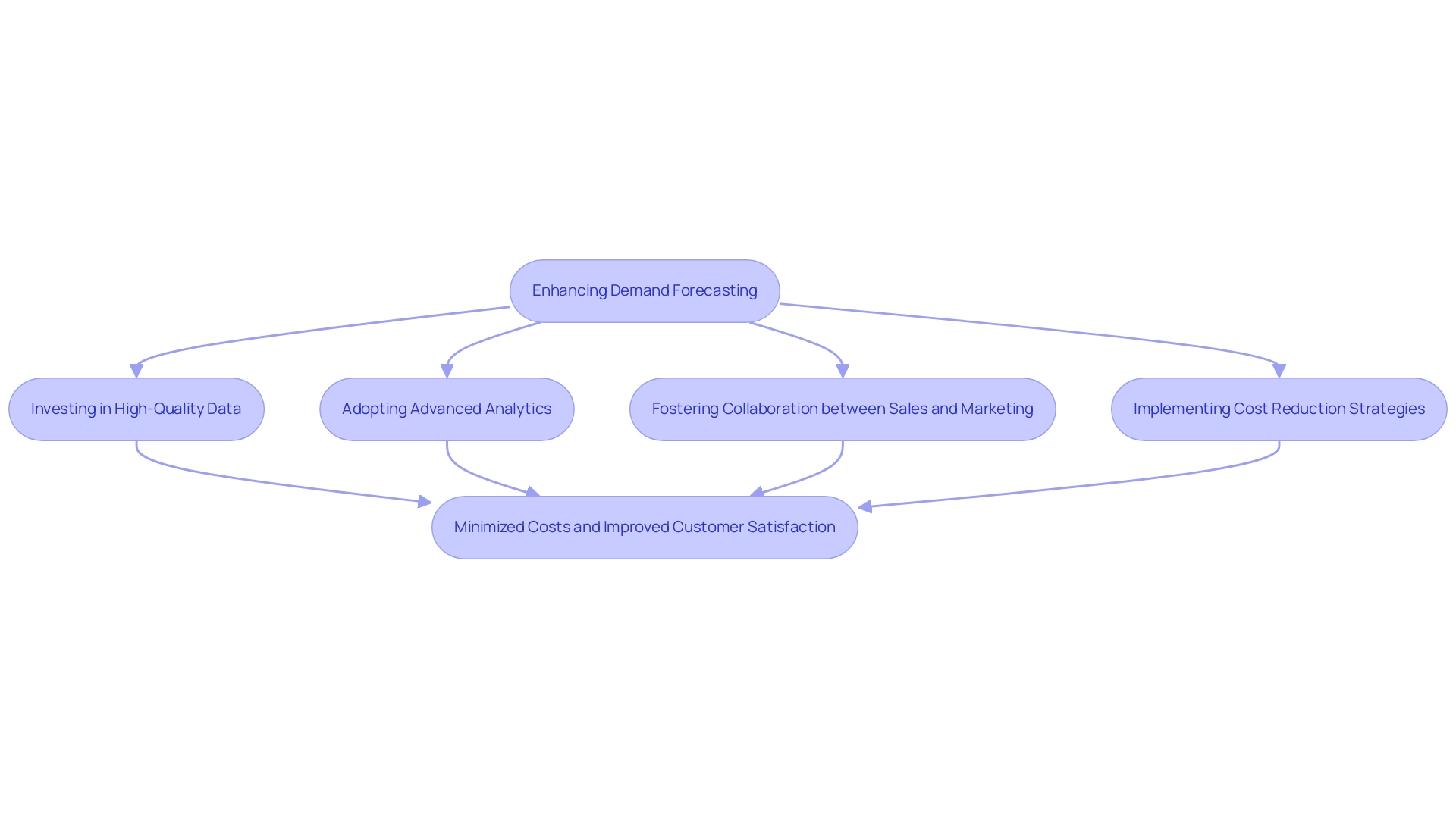

Enhancing Demand Forecasting to Minimize Costs

is essential for cost reduction strategies in supply chain management, as it helps minimize costs associated with overstocking and stockouts, which can significantly impact the bottom line. Investing in high-quality data is crucial; as statistics indicate, 66% of respondents cite the inability of reporting systems to access historical CRM or performance data as a primary barrier to accurate sales forecasting. This highlights the importance of reliable data sources in crafting effective demand plans.

By adopting advanced analytics and machine learning algorithms, companies can implement cost reduction strategies in supply chain management, thereby enhancing forecasting accuracy and enabling better alignment with market demand. Expert opinions suggest that statistical forecasting serves as an intermediate step for brands aiming to refine their predictive capabilities. Moreover, fostering collaboration between sales and marketing teams is essential for developing cost reduction strategies in supply chain management, as it provides a comprehensive understanding of market trends and customer preferences, allowing businesses to optimize inventory levels effectively.

This approach minimizes waste and enhances customer satisfaction through improved service levels. A case study on the importance of high-quality data illustrates that investing in reliable data sources helps brands set accurate targets and achieve long-term growth. As current advancements in demand forecasting technology continue to evolve, leveraging these insights becomes increasingly critical for driving sales growth and achieving long-term sustainability by implementing cost reduction strategies in supply chain management.

Strategic Supplier Negotiations for Cost Savings

Strategic supplier negotiations are critical for achieving substantial cost reduction strategies in supply chain management and for enhancing overall financial performance. CFOs should prioritize the cultivation of long-term partnerships with suppliers, focusing on collaborative pricing and flexible terms. To support these negotiations, conducting a thorough financial assessment—such as using tools like variance analysis and cash flow forecasting—can uncover opportunities for cash preservation and liability reduction, fundamentally strengthening negotiation positions.

By implementing techniques such as volume consolidation, businesses can leverage their buying power for better pricing. Additionally, early payment discounts can lead to significant savings, while exploring alternative suppliers opens up competitive options that enhance negotiation leverage. Regularly assessing supplier performance and staying informed about market conditions are essential practices that allow organizations to adapt and secure .

As highlighted by Meghan Rexer from KPMG, low touch planning not only improves Return on Equity (ROE) by 2 to 4 percentage points but also adds 1 to 3 percent to gross margins, showcasing the tangible benefits of strategic negotiations. Furthermore, the use of Best Alternative to a Negotiated Agreement (BATNA) has proven successful in gaining negotiation advantages, as emphasized by Harvard professor James Sevenius. This real-world example highlights the significance of having backup plans and exit approaches to improve negotiation results.

Furthermore, Marijn Overvest's efforts in enhancing the skills of over 200 procurement teams illustrate the importance of training and development in adapting and innovating procurement approaches for sustainable growth. Adopting these methods, supported by thorough financial evaluations, not only results in prompt savings but also cultivates within cost reduction strategies in supply chain management.

Streamlining Transportation and Logistics Operations

Enhancing transportation and logistics operations is essential for achieving in supply chain management and attaining substantial savings. Key strategies in cost reduction strategies in supply chain management include:

- Route optimization

- Consolidating shipments

- Leveraging technology for real-time tracking and management

With averaging between $2,000 to $3,000 for a 20-foot container, even small efficiency gains can translate into substantial savings.

Implementing a [Transportation Management System (TMS)](https://smbdistress.com) is a game-changer for cost reduction strategies in supply chain management, as it streamlines operations and enhances visibility, which enables improved decision-making and financial control. Faiza Iftikhar, Co-Founder of Procura Pakistan, asserts,

Knowing the latest logistics statistics is important for procurement professionals as it provides insights into trends, challenges, and opportunities in the field.

This insight emphasizes the need for access to current data to make informed decisions that optimize logistics operations.

Furthermore, investigating different transportation methods and encouraging collaborations with logistics suppliers are essential components of cost reduction strategies in supply chain management, helping to reduce expenses while upholding service quality. The freight forwarding market is expected to grow with a CAGR of more than 4% during 2021-2026, underscoring the industry's growth potential. In a competitive environment with more than 31,140 firms in the freight forwarding sector in the U.S., the need for innovative solutions is clear, particularly as last-mile delivery encounters difficulties from urban congestion and increasing expenses.

Furthermore, more than 80% of warehouses currently lack automation, presenting a significant opportunity for businesses to enhance efficiency. Implementing cost reduction strategies in supply chain management not only addresses immediate cost concerns but also positions organizations for long-term success in a rapidly evolving marketplace.

Implementing Lean Manufacturing for Enhanced Efficiency

Lean manufacturing stands at the forefront of operational excellence, focusing on the elimination of waste and fostering a culture of continuous improvement. By implementing methodologies such as 5S and Kaizen alongside Value Stream Mapping, organizations can significantly streamline production processes and enhance efficiency. Notably, lean organizations typically experience a remarkable 50% to 90% reduction in defects, underscoring the effectiveness of these strategies.

Furthermore, our approach supports a shortened decision-making cycle throughout the turnaround process, empowering your team to take decisive actions that preserve organizational health. We continually monitor the success of our plans through our client dashboard, which provides real-time business analytics that allow for ongoing diagnosis of your business health and timely adjustments. Aligning financial management initiatives with an organization’s purpose, vision, and values—as highlighted in the case study 'Connecting Financial Management with Purpose'—can substantially increase the success and sustainability of transformation efforts.

As Paul Goydan, Managing Partner and Global Leader of BCG’s Accelerated Advantage Program, articulates, 'This is a holistic financial challenge — one that's built up over five years of very rapid adjustments that companies had to make.' Such a comprehensive approach employs cost reduction strategies in supply chain management, which not only lowers expenses but also enhances product quality and responsiveness to shifting market demands, particularly as consumer buying patterns have shifted towards fewer high-end or luxury products. This makes implementing cost reduction strategies in supply chain management crucial for any CFO dedicated to .

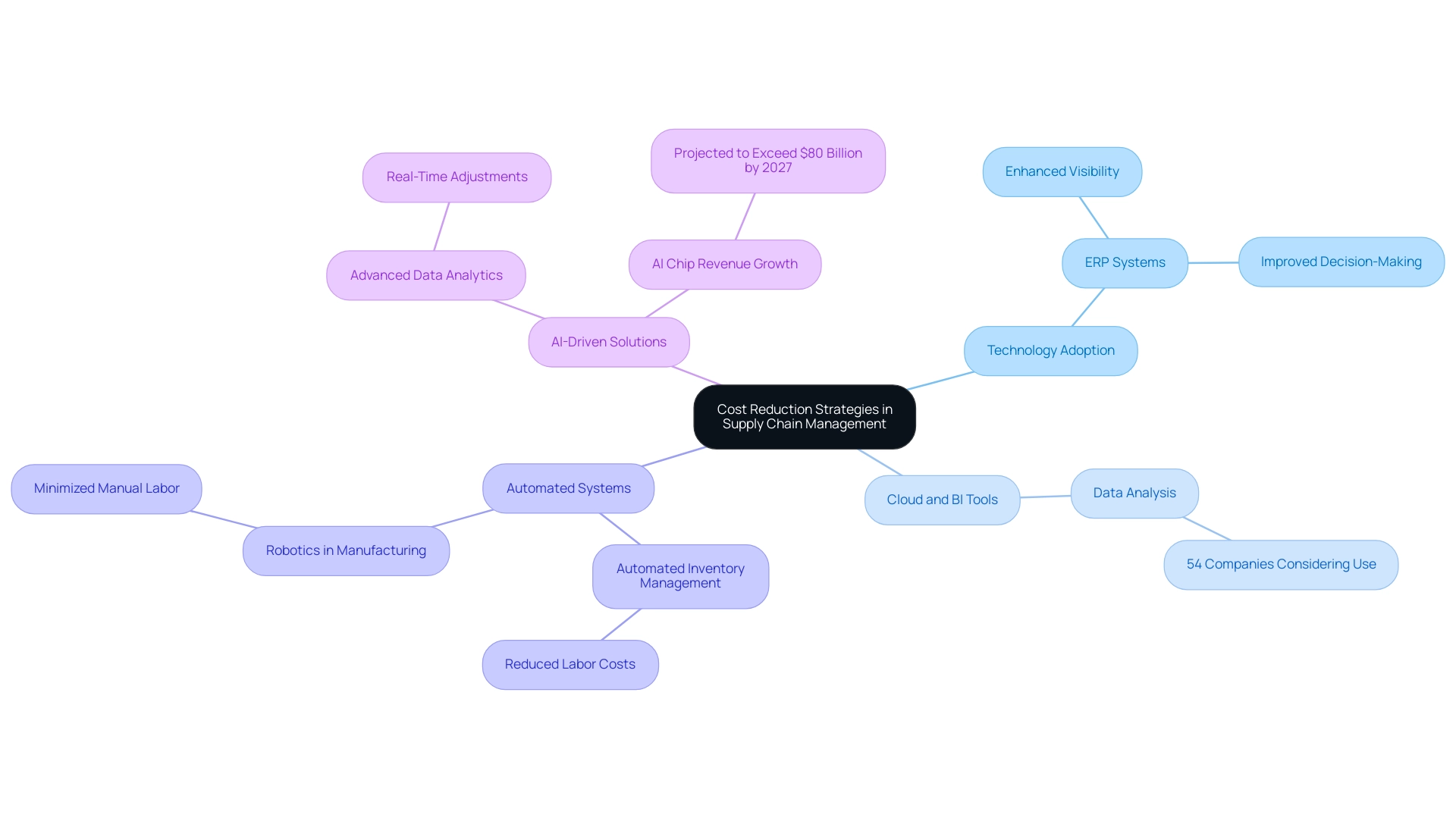

Leveraging Technology and Automation for Cost Reduction

Adopting technology and automation is essential for organizations looking to implement cost reduction strategies in supply chain management to significantly reduce operational expenses and enhance efficiency. The implementation of Enterprise Resource Planning (ERP) systems serves as a foundational step, allowing organizations to integrate various functions into a cohesive platform that enhances visibility and decision-making. Present trends suggest that 54% of businesses are investigating the use of cloud and business intelligence (BI) tools for data analysis, which is vital for promoting efficiency in supply chain operations.

As noted by GoGlobe, '54% of users agree that make their lives easier,' showcasing the growing reliance on technology to streamline operations. Additionally, automated inventory management systems and robotics are revolutionizing manufacturing processes, effectively minimizing reliance on manual labor and reducing associated costs. Research indicates that AI-driven solutions not only optimize operations but also create avenues for uncovering cost reduction strategies in supply chain management through advanced data analytics, emphasizing the need to test hypotheses and modify approaches in real time.

The projected growth of global AI chip revenue, expected to surpass $80 billion by 2027, underscores the increasing demand for hardware that supports these technologies. This case study reflects the importance of adopting a continuous performance monitoring approach while fostering strong relationships through operationalizing the lessons learned during turnaround processes. Furthermore, the 'Decide & Execute' strategy emphasizes the importance of a shortened decision-making cycle, enabling organizations to act swiftly in preserving their operations.

For CFOs aiming to improve their teams’ abilities, online courses in data analysis offer a remarkable chance to upskill, ensuring that organizations are well-prepared to take advantage of emerging trends in technology adoption for savings. Incorporating a client dashboard for real-time analytics further supports this decision-making process, allowing for timely adjustments and maximizing return on invested capital.

Exploring Outsourcing Opportunities for Cost Efficiency

Organizations can unlock significant cost reduction strategies in supply chain management by outsourcing key functions within the supply chain. It is crucial for companies to assess which processes are suitable for outsourcing without sacrificing quality. Areas commonly targeted for outsourcing include:

- Logistics

- Warehousing

- Customer service

With order processing holding the major market share in by type.

By collaborating with specialized providers, businesses can utilize cost reduction strategies in supply chain management to leverage economies of scale, gain access to industry expertise, and lower operational expenses. This strategic approach not only allows companies to concentrate on their core activities but also drives overall growth. As highlighted by Cognitive Market Research, logistics needs can vary notably between durable and non-durable goods, emphasizing the necessity for tailored outsourcing strategies.

Moreover, with projections indicating that by 2025, 60% of finance and accounting outsourcing contracts will face non-renewal due to outdated pricing models, it becomes imperative for organizations to modernize their outsourcing agreements to maintain a competitive edge. Furthermore, companies can request tailored reports and extra data at no added expense, offering further value in their outsourcing choices. For those interested in the latest trends in warehouse logistics and robotics, subscribing to Exotec's newsletter offers timely insights and updates.

This proactive approach to outsourcing logistics and warehousing can lead to substantial operational efficiencies and implement cost reduction strategies in supply chain management, resulting in savings in 2024.

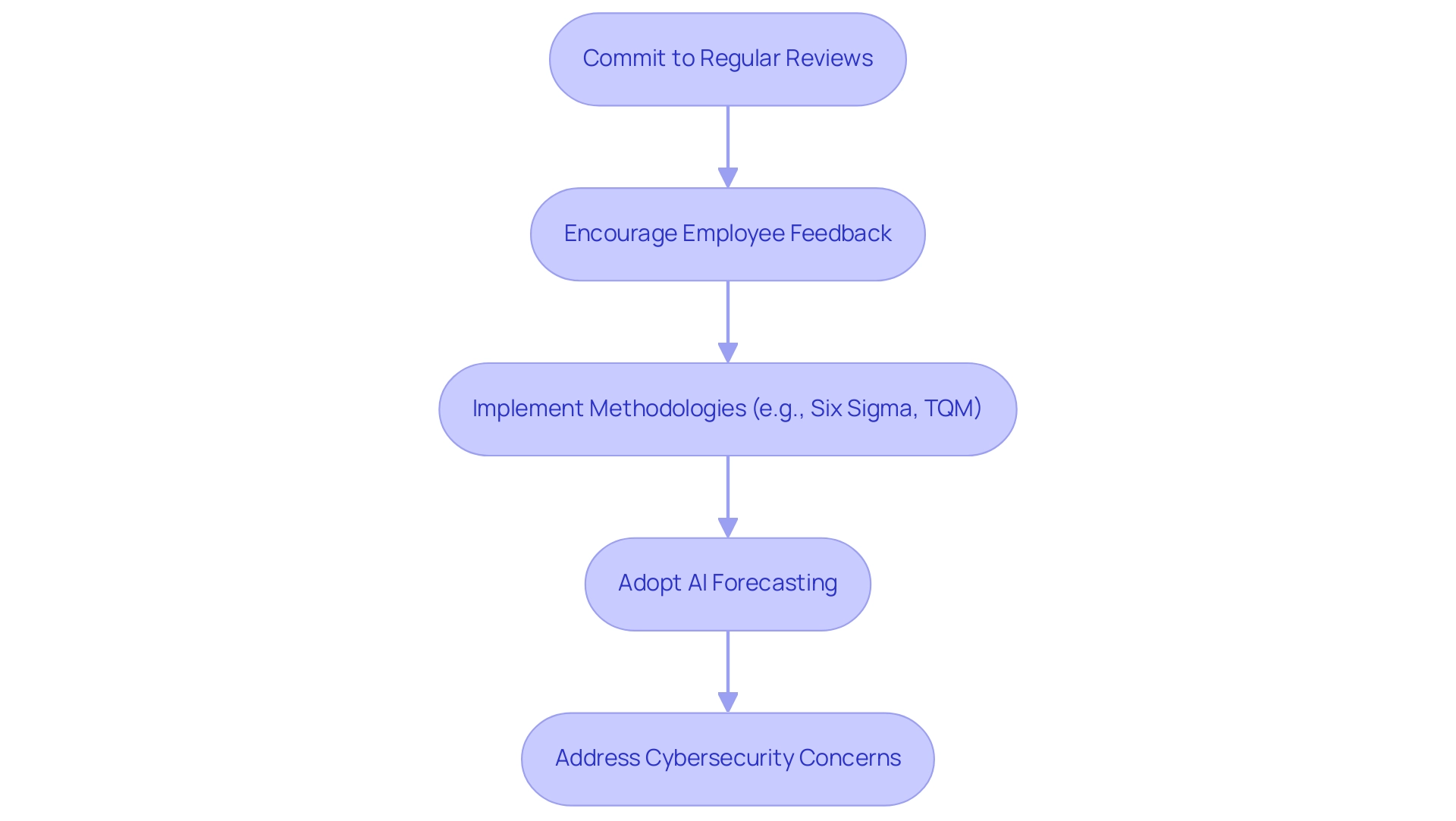

Fostering Continuous Improvement in Supply Chain Processes

Fostering a culture of ongoing enhancement within supply chain processes is crucial for maintaining efficient reduction strategies. Organizations must commit to regular process reviews, fostering an environment where feedback from employees at all levels is encouraged and valued. Implementing methodologies such as Six Sigma and Total Quality Management (TQM) serves as a powerful means to identify inefficiencies and propel enhancements throughout the supply chain.

For instance, AI forecasting can lower administrative costs by 25% to 40%, demonstrating how technology can significantly boost operational efficiency, ensuring organizations remain agile and competitive in a rapidly evolving market landscape. Moreover, as emphasized in 2023, 55.6% of organizations identified cybersecurity as a primary concern for supply chain resilience, underscoring the importance of addressing risks in continuous improvement efforts. As 2024 approaches, staying attuned to continuous improvement trends becomes increasingly critical, with insights from a recent Gartner survey emphasizing the necessity for supply chain leaders to adapt to disruptive technologies.

Notably, Schneider Electric was recognized as the top supply chain of 2023 for its growth, inventory management, and ESG strategies, serving as a real-world example of effective supply chain management practices. The emphasis on continuous improvement not only enables businesses to respond to market fluctuations but also solidifies their long-term strategic advantage.

Conclusion

Operational efficiency is no longer just a goal; it is a necessity in today’s competitive environment. By implementing cost reduction strategies such as:

- Just-In-Time inventory management

- Advanced demand forecasting

- Strategic supplier negotiations

CFOs can significantly enhance their organizations’ bottom lines. These approaches not only lead to immediate savings but also foster long-term sustainability and growth.

Moreover, the integration of technology and automation within logistics and manufacturing processes streamlines operations, reduces reliance on manual labor, and opens avenues for continuous improvement. Embracing methodologies like:

- Lean manufacturing

- Outsourcing key functions

further empowers organizations to focus on their core competencies while optimizing resource allocation.

As the landscape continues to evolve, fostering a culture of continuous improvement is essential. By regularly assessing processes and adapting to emerging trends, organizations can maintain their competitive edge and ensure resilience against market fluctuations. The strategies outlined provide a comprehensive framework for CFOs to drive cost efficiency and innovation, positioning their companies for success in the ever-changing business landscape.

Frequently Asked Questions

Why is efficient inventory control important?

Efficient inventory control is essential for matching stock levels with customer demand and implementing cost reduction strategies in supply chain management to minimize unnecessary holding expenses.

What is Just-In-Time (JIT) inventory control?

Just-In-Time (JIT) inventory control is a strategy that synchronizes inventory orders with production schedules to significantly reduce excess stock, cut down on carrying costs, and enhance cash flow.

What is the ABC analysis in inventory management?

The ABC analysis categorizes inventory into three groups based on importance: A for high-value items, B for moderate-value items, and C for low-value items, allowing businesses to focus their oversight on the most critical stock.

What was the average global stock turn over the past year?

The average global stock turn over the past year was 5.3, serving as a benchmark for evaluating inventory effectiveness.

What is the projected worth of the inventory control software market by the end of 2024?

The inventory control software market is expected to reach a worth of $2,191.2 million by the end of 2024.

How do labor considerations impact cost reduction strategies in supply chain management?

Labor considerations, such as warehouse worker salaries, play a significant role in cost reduction strategies, making it essential for CFOs to factor these elements into their inventory management plans.

Why is accurate demand forecasting crucial in supply chain management?

Accurate demand forecasting is crucial because it helps minimize costs associated with overstocking and stockouts, which can significantly impact a company's bottom line.

What percentage of respondents cite reporting system limitations as a barrier to accurate sales forecasting?

66% of respondents cite the inability of reporting systems to access historical CRM or performance data as a primary barrier to accurate sales forecasting.

How can companies enhance forecasting accuracy?

Companies can enhance forecasting accuracy by adopting advanced analytics and machine learning algorithms, which help align inventory levels with market demand.

What role does collaboration between sales and marketing teams play in inventory management?

Collaboration between sales and marketing teams is essential for developing cost reduction strategies, as it provides a comprehensive understanding of market trends and customer preferences, optimizing inventory levels effectively.

How does investing in high-quality data benefit businesses?

Investing in high-quality data helps brands set accurate targets, achieve long-term growth, and minimize waste, ultimately enhancing customer satisfaction through improved service levels.